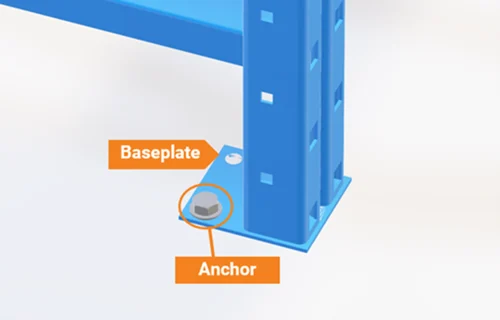

Pallet rack anchors may be small, but they’re one of the most critical components of any warehouse racking system. Anchors secure the baseplate of the upright to the concrete floor, helping stabilize the entire structure and prevent tipping or shifting under load.

At Total Warehouse, we emphasize proper anchoring as a key part of warehouse safety and compliance. Whether you’re installing new racking or inspecting existing systems, ensuring anchor integrity should always be a top priority.

Why Anchor Condition Matters

Anchors are designed to keep your pallet racking system firmly in place, even during heavy loading, forklift movement, or seismic activity. If an anchor is missing, loose, or sheared off, it compromises the stability of the entire bay—and increases the risk of collapse.

Damaged or missing anchors can lead to:

- Rack sway or misalignment

- Baseplate bending or tearing

- Upright column failure during impact

- Spreading bays in drive-in or high-density systems

- Serious safety risks for warehouse personnel

This is especially critical in high-traffic areas or in systems like drive-in racking, where repeated equipment entry puts added stress on rack bases.

Signs Your Anchors May Need Inspection or Repair

Regular visual inspections should be part of your warehouse maintenance routine. Look for:

- Missing anchors at any upright base

- Anchors that appear loose or unstable

- Sheared or snapped anchor bolts

- Torn, bent, or twisted baseplates

- Uprights leaning or pulling away from the floor

According to safety standards like ANSI MH16.1, any baseplate that is visibly twisted more than ½ inch or missing anchors must be addressed immediately.

Choosing the Right Anchors for Your Pallet Rack System

Proper anchoring is essential to the safety and performance of any pallet racking system. At Total Warehouse, we evaluate, specify, and install anchors that meet engineering and seismic requirements—especially for high-impact and high-risk zones across the West Coast.

Here’s a quick breakdown of common anchor types and why your selection matters.

Why We Recommend Wedge Bolts

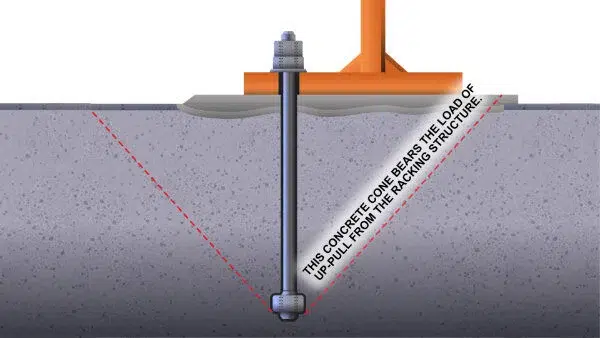

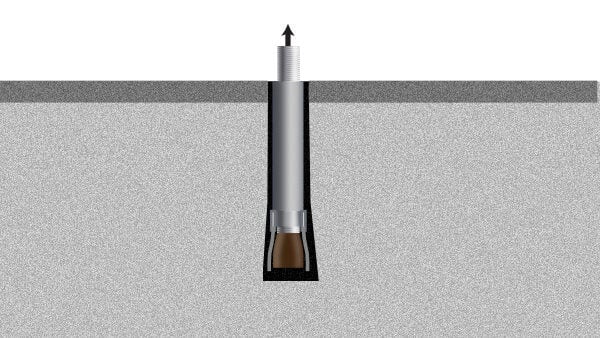

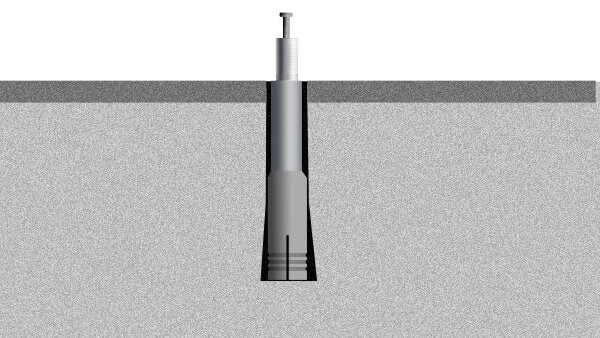

Wedge bolts are the preferred solution for most racking applications due to their strength, durability, and seismic compatibility. These anchors expand at the base when torqued to spec, creating a high-tension, secure connection to the concrete slab.

Key benefits:

- Stronger tension and shear capacity than strike anchors

- Ideal for high-traffic and seismic zones

- Can be retightened if loosened after impact

- Engineered for reusability when properly maintained

We use wedge bolts when performing structural rack repairs or installing engineered kits, ensuring your system meets safety and load-bearing requirements.

Why Strike Anchors Are Not Recommended

Strike anchors, while easier to install and remove, offer significantly lower strength ratings and cannot be reused. They’re more prone to failure in seismic zones or under heavy use, which is why we don’t recommend them for warehouse environments requiring high reliability.

The Role of Baseplates and Anchor Placement

Every rack upright sits on a baseplate, which must align with OEM specs for anchor size, hole spacing, and thickness. Choosing a thicker steel footplate improves impact resistance and helps distribute load during forklift strikes or seismic events.

Important considerations:

- Anchor holes must avoid rebar and be properly spaced

- Plate thickness affects overall rack system resilience

- Seismic applications often require larger or custom footplates

Our team ensures all anchors are installed to manufacturer and code specifications, including those required for seismic engineering compliance.

Free Rack Anchor Assessments from Total Warehouse

The integrity of your pallet racking system starts at the ground level. Anchors play a critical role in maintaining structural stability, and even minor issues can lead to serious safety risks if left unaddressed. At Total Warehouse, we offer complimentary on-site anchor evaluations to help facility managers stay ahead of potential failures and maintain a safe, compliant operation.

As part of our assessment, we examine:

- Proper anchor installation and quantity per upright

- Compatibility with rack design and load specifications

- Baseplate condition, spacing, and alignment

- Overall rack-to-floor connection stability

If we identify compromised or missing anchors, our team provides clear, expert guidance on corrective actions—whether that involves re-anchoring, reinforcement, or broader system adjustments. All recommendations are grounded in current safety standards and decades of field experience.

We support clients across a wide range of rack types and operating environments, offering services such as:

- Anchor and baseplate repair or replacement

- Structural evaluations of uprights and braces

- Installation of safety reinforcements including rack guards

- System re-leveling or reconfiguration following impact or modification

Whether you’re responding to visible damage or preparing for regulatory review, Total Warehouse delivers practical, reliable solutions tailored to your facility’s needs.

To schedule your no-cost rack anchor assessment, contact our team today. We’re here to ensure your racking systems are built—and maintained—for lasting performance and safety.