Determine the Right Capacity for Your Operational Needs

If you’re uncertain about the forklift capacity needed for your operations, contact the experts at Total Warehouse and prepare to answer these 4 questions.

- How heavy is your general load?

- What is the maximum height your load needs to be lifted to?

- How wide is your largest possible load?

- Will you require any attachments?

X = Load Center

Y = Effective Thickness

Forklift Load Center and Capacity Calculations

Forklift Load Center: Measure the length of the load you’re lifting and divide that number by 2. Ex. If lifting a pallet that’s 48 inches long, load center would be 24 inches from face of forks.

Forklift Lifting Capacity: Rated load center ÷ Actual load center x Rated capacity of Lift

Revised Capacity: (Truck capacity x Load center) / (New load center)

New Capacity: Base capacity x (Base LC ÷ New load center)

Forklift Derated Calculator

| Forklift Derate Calculator | |

|---|---|

| Rated Load Center (in.) | The original horizontal load center that is rated for your forklift. |

| New Load Center (in.) | This is typically the length from the mast to the center of the new load. |

| Rated Capacity (lbs) | The rated capacity for the height you are lifting the load to. |

| Derated Capacity | 0.00 lbs |

Rated Load Center: This is the forklift’s rated horizontal load center, as specified on the forklift’s data card.

New Load Center: The new horizontal load center, calculated by adding the effective thickness of any attachments to the original load center. It represents the distance from the mast to the center of the new load.

Rated Capacity: The lifting capacity at a given height, noted on data plate. Adjust by subtracting any added attachment weight not included in original capacity rating.

Example:

Rated Load Center: 32 in | New Load Center: 45 in | Rated Capacity: 3,000 lbs | DeRated Capacity: 2,133 lbs

Forklift Capacity and Load Center – Everything To Know

Forklift capacity and load center are important for safety, efficiency, and equipment longevity.

Safety: A forklift’s capacity and load center are important for safety because overloading a forklift can cause it to tip over, which can lead to injuries or fatalities.

Efficiency: A forklift that operates within its load capacity performs optimally, which ensures smooth and efficient handling of materials.

Equipment Longevity: Operating a forklift beyond its load capacity can cause excessive wear and tear on its components, leading to premature failure.

Forklift Load Center

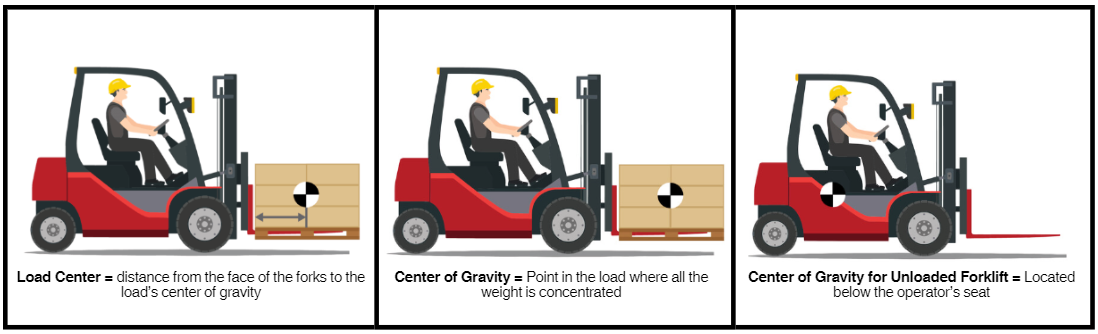

The load center is the distance between the vertical part of the forks (the face) and the center of gravity of the load being carried. In most forklifts, this distance is typically rated at 24 inches.

Center of Gravity

The center of gravity refers to an imaginary point within an object where all of its weight is concentrated. This concept is crucial for maintaining balance and stability, especially when lifting heavy loads with a forklift. Understanding these concepts is essential for safe and efficient forklift operation, ensuring that the load is balanced and the equipment is used within its rated capacity.

Load Capacity

Load capacity refers to the maximum weight a forklift can safely lift and carry. This capacity is closely tied to the load center, the distance from the load’s center of gravity to the front face of the forks. It’s important to ensure that loads are centered when lifting to maximum height or carrying at maximum capacity to maintain stability and safety. The load capacity can vary based on several factors, including the use of attachments, the height to which the load is lifted, and the overall balance of the forklift.

Net Capacity

Net capacity, also known as payload capacity, takes into account additional elements that may impact the forklift’s lifting capabilities. This includes attachments, the style of the mast, and any other add-ons. The net capacity represents the actual weight a forklift can safely handle when these factors are considered. Understanding net capacity is crucial for ensuring that the forklift operates within its safe limits, preventing accidents and equipment damage.

Importance of Load Center

When operating a forklift, maintaining load stability is crucial for safe and efficient handling. A key factor in this is understanding the load center.

The Role of the Counterweight

In a loaded forklift, the counterweight plays a vital role in balancing the load on the forks. The counterweight must effectively offset the load to prevent tipping.

The Importance of Centering the Load – If the load is not properly centered, it can destabilize the forklift. This imbalance increases the risk of tipping, which can lead to serious injury or even death.

Forklift Weight Considerations – Did you know that forklifts typically weigh about three times their rated lift capacity? This significant weight helps ensure stability, but only when the load is correctly centered and balanced.

By understanding these principles, you can keep both your forklift and its load stable, ensuring a safer working environment.

At Total Warehouse, we’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.