One of the most overlooked aspects of warehouse safety is pallet rack capacity labeling. While structural integrity and anchoring are essential, clearly posted capacity labels ensure your team understands the limits of each bay—and helps prevent dangerous overloading that can lead to rack failure.

At Total Warehouse, we help clients properly identify, label, and maintain racking systems to meet OSHA and ANSI MH16.1 standards.

What Is Pallet Rack Weight Capacity?

Storage rack load capacity refers to the maximum safe load that a rack beam level or upright frame can support. This is determined by several factors, including:

- Upright frame design and spacing

- Beam size, gauge, and connection style

- Type and weight of pallets being stored

- Seismic zone and floor load ratings

Understanding pallet rack weight capacity goes beyond knowing how much weight each beam level can hold — it also requires awareness of the “unsupported span,” or the vertical distance between beam levels within the racking system. This spacing plays a critical role in overall rack integrity. As the unsupported span increases, the structural strength of the upright frame decreases, which can reduce how much weight the entire system can safely hold. In warehouse environments where maximizing vertical space is a priority, it’s easy to overlook the trade-off between taller configurations and load capacity, but this oversight can pose serious safety risks.

The largest unsupported span within a racking system essentially sets the tone for the entire rack’s weight capacity. Longer spans increase the chance of beam deflection and can introduce more stress to the upright frames, especially when heavy pallets are involved. That’s why it’s essential to maintain proper beam spacing based on manufacturer guidelines. Reinforcements such as sway braces and correctly placed diagonal supports can help distribute the load and improve rack stability, but they don’t eliminate the need for accurate weight assessments and conservative loading practices.

To optimize pallet rack performance and ensure warehouse safety, companies should routinely inspect their racking systems and verify that all weight loads remain within the rated capacity — especially when reconfiguring beam levels or handling different pallet types. Floor conditions, such as concrete thickness and flatness, also influence rack safety and performance. Investing time in rack layout planning, understanding unsupported spans, and training warehouse personnel on weight distribution can prevent costly accidents and maintain OSHA compliance while maximizing storage efficiency.

Exceeding these limits—even temporarily—can weaken your system, stress key components, and put your team and inventory at risk.

Why Storage Rack Capacity Labels Matter

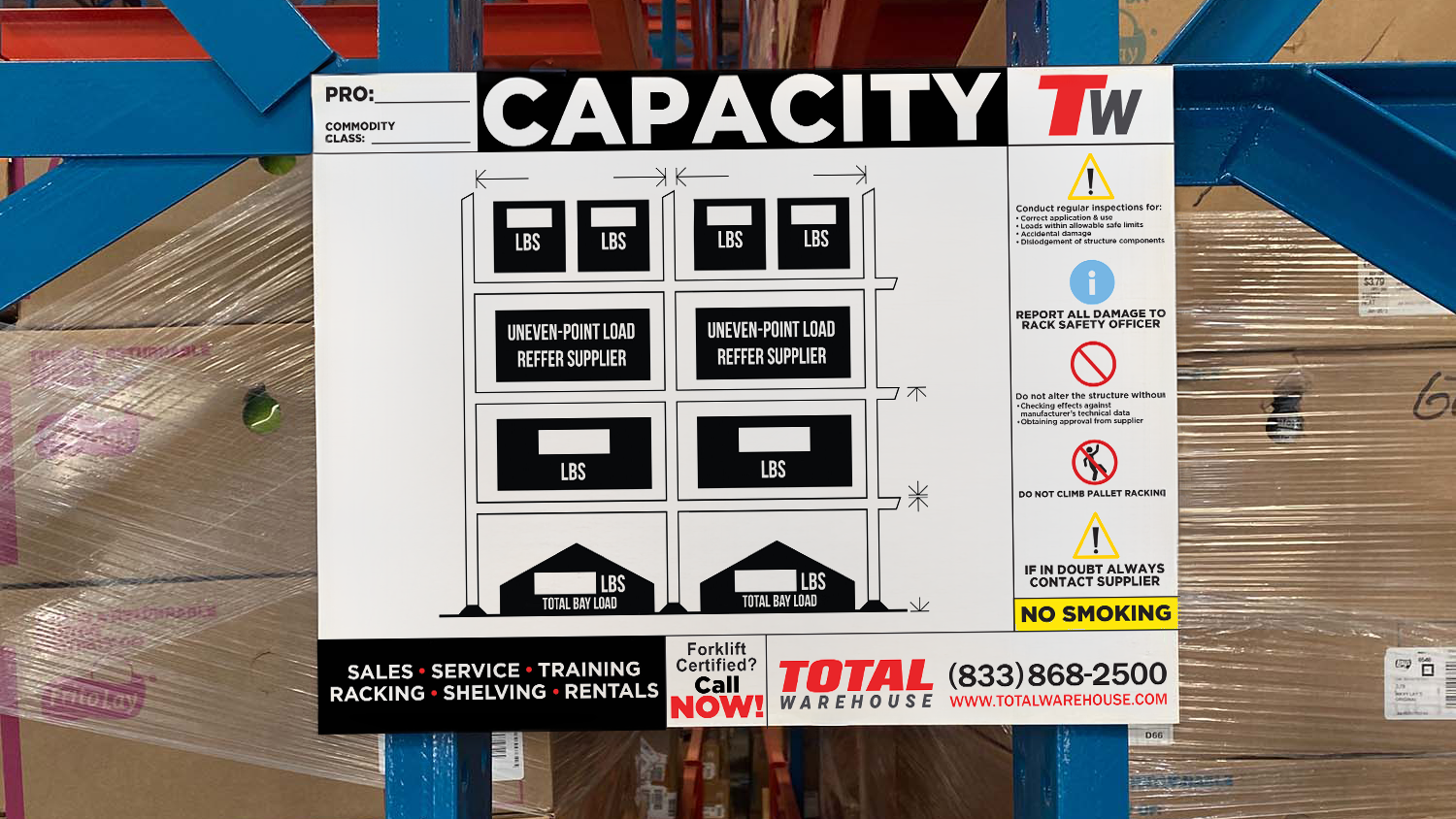

According to RMI (Rack Manufacturers Institute) guidelines, all pallet shelving racks must have clearly visible load capacity labels installed on each bay. These labels provide critical details such as:

- Maximum beam load per level

- Total bay load capacity

- Manufacturer or engineering contact info

- Rack system model/type

Without proper labeling, even well-trained operators can unknowingly overload storage bays. Worse, unlabeled or inaccurate racks can lead to compliance violations during audits or inspections.

Stay Compliant and Confident with Total Warehouse

If your warehouse racking is missing capacity labels—or if you’ve recently reconfigured your system—Total Warehouse offers free site consultations to help you:

- Verify accurate rack capacity based on system specs

- Supply and install up-to-date capacity labels

- Evaluate load distribution and rack configuration

- Ensure your system meets ANSI MH16.1 and OSHA guidelines

We work directly with engineering partners and leading manufacturers to validate load ratings and provide clients with peace of mind that their systems are both safe and fully documented.

Don’t leave safety to guesswork. Let Total Warehouse help you get your rack system labeled, compliant, and load-ready.