Key Takeaways

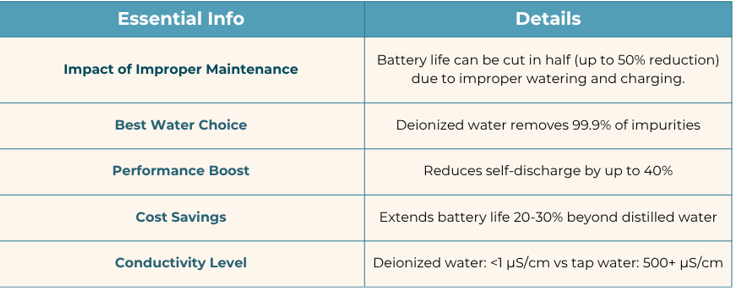

Did you know that a simple act like watering your forklift battery correctly could double its lifespan? A typical forklift battery is built to last about five years, but neglecting proper watering and charging can slice that lifespan in half. I learned this the hard way early in my career, and trust me, replacing a forklift battery is a costly mistake to avoid.

Overlooking regular watering can slash your battery’s life expectancy by as much as 50%, forcing you into expensive replacements that could have been easily avoided and so I’ve put together this guide to share everything I’ve learned about watering forklift batteries, from the basics to the pro-tips that will save you time and money.

What Is Deionized Water and Why Your Batteries Crave It

Now, let’s talk about the type of water you should be using. This is where a lot of people go wrong. You can’t just use water straight from the tap. I made this mistake once, thinking “water is water,” and it cost me a battery.

- Tap water is a no-go. It contains dissolved minerals and salts that can build up on the battery plates, which seriously shortens the battery’s life and run times.

- Chlorine, which is added to some city water supplies, can also damage your battery.

- The best choice for lead-acid batteries is deionized water.

Deionization is a process that purifies water by removing dissolved minerals and salts. It’s even more effective than distillation or conventional filters. The minerals in regular water can interfere with the battery’s cell voltage and increase self-discharge, which means your battery won’t hold a charge for as long. Deionized water also helps reduce corrosion of the cells.

The Science Behind Deionization

Deionized water goes through a process that removes virtually all dissolved minerals and salts – not just most of them, but nearly every ionic particle. Regular distillation removes a lot, but deionization takes it to the next level.

Here’s what blew my mind: deionized water has a conductivity of less than 1 microsiemen per centimeter, while our “clean” tap water measured over 500. That’s a massive difference in electrical interference.

Why Minerals Are Forklift Battery Killers

Here’s why minerals and dissolved particles are harmful to the batteries:

- Build up on battery plates over time

- Create electrical paths that cause self-discharge

- Interfere with the chemical reactions inside cells

- Reduce the battery’s ability to hold a charge

The mineral buildup acts like tiny conductors inside your battery, slowly draining power even when the forklift isn’t running.

FAQs

- Can I use distilled water instead of deionized water?

- While distilled water is better than tap water, deionized water is recognized as the best choice for maintaining lead-acid batteries.

- Where can I get deionized water?

- You can purchase it from auto parts stores or industrial supply companies.

How to Water a Forklift Battery: Step-by-Step

Before you start, safety should be your top priority. I can’t stress this enough.

- Always wear personal protective equipment (PPE) like safety goggles, gloves, and an apron to protect yourself from acid splashes.

- Make sure there’s an eyewash station within 20 feet.

- The forklift should be turned off, and the key removed.

- Work in a well-ventilated area and avoid any open flames or smoking, as charging can produce hydrogen gas.

The Watering Process – Manual Method

If you’re manually watering your forklift battery, follow these steps:

1) Locate the battery’s fill holes or vent caps on the top of each cell.

2) Remove the vent caps, using a tool if needed.

3) Slowly pour distilled water into each cell using a watering jug or gun. Be careful to fill each cell evenly and avoid overfilling.

4) Stop when the electrolyte level reaches the recommended height.

5) Securely replace the vent caps to prevent contamination and evaporation.

The Watering Process – Automated Method

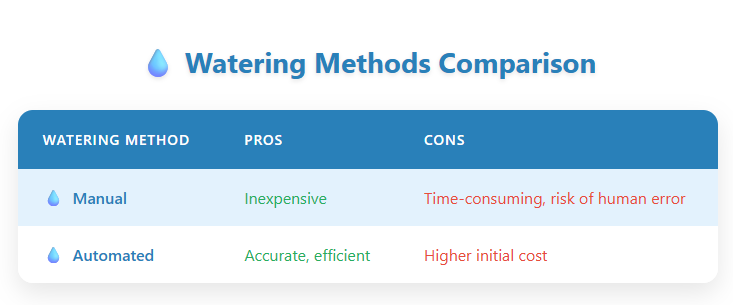

Automated battery watering systems are a game changer for large operations or businesses seeking to optimize maintenance.

These systems connect directly to the vent caps and automatically fill each cell to the correct level.

All you need to do is attach the system to a water source, and it will handle the rest—ensuring consistent, accurate water levels without the risk of under- or over-watering.

Why is Battery Watering Important?

Proper maintenance is everything when it comes to forklift batteries. Think of it like this – you wouldn’t drive your car for years without an oil change, right? The same principle applies here. Consistent watering and charging are the keys to unlocking the full potential of your investment.

- A well-maintained battery can last its full five-year lifespan

- Neglecting maintenance can cut that lifespan in half

- Regular watering prevents costly and premature replacements

I’ve seen firsthand how a little bit of time spent on maintenance each week can pay off in the long run. It’s not just about avoiding the cost of a new battery; it’s about keeping your operations running smoothly without unexpected downtime.

FAQs

- How much can I save by properly maintaining my forklift battery?

- While it varies, you can save thousands of dollars by avoiding premature replacements.

- Is it really necessary to water the battery every week?

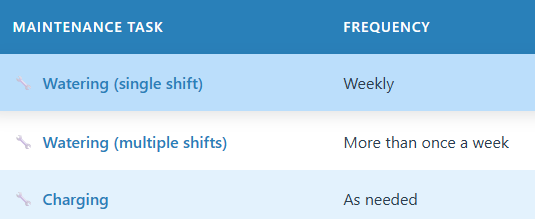

- Yes, for a single-shift operation, weekly watering is the standard recommendation.

When Is Watering Necessary?

Most forklift batteries, especially the lead-acid types, need regular watering to keep their electrolyte levels in check. The process of charging and discharging causes some of the electrolyte to evaporate, and adding water keeps everything balanced.

As a rule of thumb, a forklift running one shift per day should be watered weekly. However, if you’re running multiple shifts or using reconditioned batteries, you’ll need to water them more often. The golden rule is to always water the battery after it’s fully charged and has had time to cool down.

Checking the Electrolyte Levels

There are two common ways to check the battery’s electrolyte levels:

- Visual Inspection: Take a look at the electrolyte levels in each cell. If they’re below the top of the plates, it’s time to add water.

- Float or Eye Indicators: Some batteries have built-in indicators that will let you know when it’s time to water them. Check the manufacturer’s guidelines for specific instructions.

The Watering Process

If you’re watering the battery manually, here’s what you need to do:

- Find the battery’s fill holes or vent caps on top of each cell.

- Remove the vent caps.

- Slowly pour distilled water into each cell using a watering jug or gun.

- Be careful to fill each cell evenly and don’t overfill them.

- Stop when the electrolyte level reaches the recommended height.

- Securely replace the vent caps.

For larger operations, an automated battery watering system can be a real lifesaver. These systems connect directly to the vent caps and fill each cell to the correct level automatically.

The Payoff of Proper Maintenance

Regular maintenance of your lead-acid forklift batteries will help preserve their capacity and could increase their life and run times34. This means less downtime, increased productivity, and more money in your pocket35. One of the most important parts of this maintenance is keeping an eye on the water levels and adding water when needed to get the best performance36.

In my experience, the businesses that are the most successful are the ones that pay attention to the small details, and battery maintenance is one of those details that makes a big difference.

FAQs

- How much time does it take to water a forklift battery?

- With a manual watering system, it can take 15-20 minutes. An automated system can do it in a fraction of that time.

- What happens if I overfill the battery?

- Overfilling can cause the electrolyte to boil over during charging, which can damage the battery and create a safety hazard37.

In closing, taking care of your forklift batteries isn’t just a chore; it’s a smart business practice. By following these simple guidelines, you can get the most out of your investment and keep your operations running smoothly. I encourage you to create a regular maintenance schedule and stick to it. And if you have any of your own tips or experiences to share, please leave them in the comments below!