With over fifteen years of specialization in forklift maintenance and service operations, I have consistently observed that organizations implementing proactive forklift care strategies achieve superior operational outcomes compared to those relying on reactive repair approaches. The distinction between systematic forklift maintenance and emergency-driven service calls often determines warehouse productivity, safety compliance, and long-term equipment investment returns.

The Critical Role of Forklift Service Programs

Forklifts represent the backbone of modern material handling operations, yet they are treated with insufficient attention until failure occurs. This reactive approach to forklift maintenance creates operational vulnerabilities that extend throughout the entire supply chain, affecting everything from inventory management to customer delivery commitments.

Understanding Forklift-Specific Maintenance Challenges

Direct Financial Impacts

- Productivity Losses: A single forklift breakdown can halt entire warehouse operations, with productivity losses often exceeding $500-1,000 per hour depending on facility size and throughput requirements.

- Emergency Service Premiums: After-hours forklift repairs typically cost 150-200% more than scheduled maintenance, while emergency parts sourcing adds additional expense and delay.

- Operator Idle Time: Forklift downtime creates immediate labor inefficiencies as operators await equipment restoration or alternative assignment.

Indirect Operational Consequences

- Customer Service Disruption: Forklift failures can delay shipments, compromise delivery schedules, and ultimately impact customer satisfaction and retention.

- Safety Incident Risk: Poorly maintained forklifts pose significant safety hazards, with potential liability costs far exceeding maintenance expenses.

- Insurance and Compliance Issues: Inadequate forklift maintenance can result in insurance claims, regulatory violations, and increased premium costs.

Comprehensive Forklift Service Solutions

Modern forklift service programs encompass far more than basic mechanical repairs. Effective programs integrate preventive maintenance, predictive diagnostics, and performance optimization to maximize equipment availability and operational efficiency.

Essential Forklift Service Components

- Preventive Maintenance Schedules: Systematic inspection and service intervals based on operating hours, load cycles, and manufacturer specifications ensure optimal forklift performance and longevity.

- Hydraulic System Services: Specialized hydraulic maintenance including fluid analysis, filter replacement, seal inspection, and pressure testing to maintain lifting precision and safety.

- Battery Maintenance Programs: Comprehensive battery care including electrolyte management, charging system optimization, and terminal maintenance to maximize electric forklift performance.

- Attachment Servicing: Specialized maintenance for forklift attachments ensuring proper operation, safety compliance, and extended service life.

- Diagnostic Services: Advanced forklift diagnostics using manufacturer-specific equipment to identify potential issues before they result in operational failures.

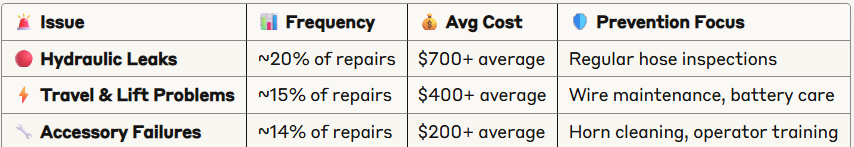

The Most Common Forklift Issues

Based on our data of thousands of forklift repair calls, hydraulic leaks account for roughly one in five forklift breakdowns, yet most facilities I’ve visited don’t even have a basic leak prevention protocol. That’s like ignoring a ticking time bomb in your warehouse. After reviewing extensive repair data and combining it with my own hard-learned lessons, I’m sharing the three most critical forklift issues that’ll either make or break your operation.

🔴 Issue #1: Hydraulic Leaks – The Silent Killer

Here’s what really gets under my skin about hydraulic leaks – they’re completely preventable, yet they’re the top reason forklifts end up in the repair bay. I learned this the hard way when I had three units down simultaneously because nobody was checking the obvious warning signs.

Picture this: You walk into your warehouse Monday morning, and there’s a perfect puddle of hydraulic fluid under your best reach truck. That puddle represents more than just a mess – it’s lost productivity, safety hazards, and a repair bill that could’ve been avoided with a five-minute inspection.

Root Causes and Repair Strategies:

• Blown hoses and damaged tubing (roughly 40% of leak cases)

- These babies fail because of constant pressure and movement

- The mast hoses take the worst beating – they’re flexing thousands of times per day

- Pro tip from the trenches: Replace hoses when you see the metal wire framework peeking through

• Loose fittings and clamps (about 10% of cases)

- Usually happens gradually – fittings work themselves loose over time

- Quick torque check during PM can catch these before they become puddles

• Failing seals and O-rings (roughly 18% combined)

- These are the sneaky ones – they start as a “weep” before becoming a full leak

- Watch for telltale signs: fluid residue without ground contact means replacement time

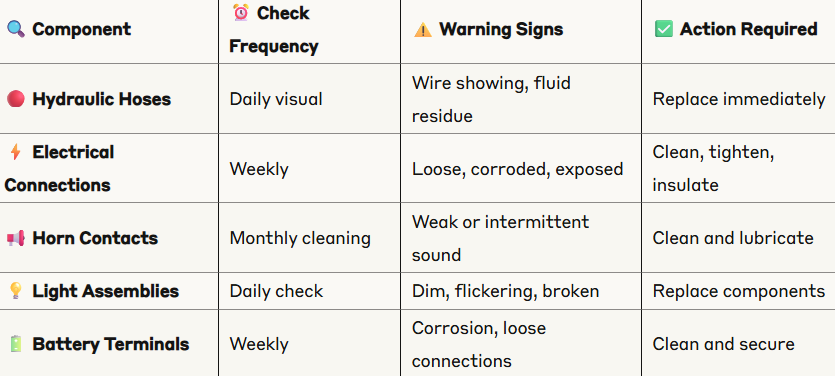

Daily visual inspections save thousands. Train your operators to spot the difference between a weep and a leak – one’s preventable maintenance, the other’s emergency repair time.

Common FAQs on Hydraulic Leaks:

- Q: How often should hydraulic hoses be replaced? A: Replace when you see wire reinforcement or every few years for high-movement hoses

- Q: Can small leaks wait? A: Never ignore leaks – they create slip hazards and always get worse

⚡ Issue #2: Travel and Lift Malfunctions – When Your Workhorse Won’t Work

Nothing’s more frustrating than a forklift that won’t lift or move when you need it most. These problems hit about 15% of all service calls, and I’ve personally dealt with more than my share of units that decided to quit mid-shift.

The worst case I remember? Our main order picker died during peak season because of a broken wire that could’ve been spotted during routine maintenance, which cost us two days while we waited for parts.

Primary Failure Points:

• Broken or corroded wiring (roughly 17% of travel/lift issues)

- Heat, age, and constant movement create the perfect storm for wire failure

- Electric units are particularly vulnerable – all that current flowing through aging wires

- Reality check: I’ve seen wires so brittle they’d snap if you looked at them wrong

• Malfunctioning switches and contactors (about 16% of cases)

- Contactors in electric forklifts take a beating from constant engagement

- These usually fail without warning – one day they work, the next they don’t

• Battery-related movement issues (roughly 10% of occurrences)

- Weak batteries don’t just affect starting – they kill performance too

- Under-charged batteries can’t provide the power needed for normal operation

Electrical tape is your friend – but only as a temporary measure. Any exposed wire needs proper insulation or replacement. Battery discipline makes the difference. Keep them watered, keep them charged, and never put a partially charged battery into service.

Common FAQs about Travel/Lift Problems:

- Q: Why do electric forklift wires fail more often? A: Higher electrical loads and more complex wiring systems create more failure points

- Q: How can I tell if a battery is truly dead? A: Load test it – weak batteries might start the unit but won’t sustain operation

🔧 Issue #3: Accessory Failures

Don’t let the ~14% frequency fool you – accessory failures can shut down your operation just as fast as major mechanical issues. OSHA doesn’t care if “it’s just a horn” – no working horn means no operating forklift.

I’ve had inspectors red-tag units for burnt-out backup alarms and faulty horn contacts. The frustrating part? Most of these failures are completely preventable with basic maintenance.

Most Common Accessory Problems:

• Dirty or worn components (roughly one-third of accessory issues)

- Horn contacts are the biggest culprit – they need regular cleaning and lubrication

- Light bulbs burn out, but operators often don’t report them until inspection time

- Pro maintenance tip: Clean horn contacts with di-electric grease every PM cycle

• Damaged assemblies (about 28% of cases)

- Headlights, taillights, and travel alarms get smashed by careless operation

- These are usually operator-damage issues, not mechanical failures

• Broken accessory wiring (roughly 19% of failures)

- Vibration and movement gradually work connections loose

- Check connections during routine maintenance – loose is fixable, broken costs money

Operator accountability cuts damage by half. When people know they’re responsible for reporting damage, they drive more carefully.

Common FAQs about Accessory Maintenance:

Q: How often should horn contacts be cleaned? A: Monthly cleaning with di-electric grease prevents most failures

Q: Are LED lights worth the extra cost? A: Absolutely – they last longer and draw less power

🛠️ Essential Maintenance Quick Reference

Selecting Expert Forklift Service Providers

The complexity of modern forklift systems requires specialized expertise that extends beyond general mechanical knowledge. Organizations must carefully evaluate service providers to ensure comprehensive forklift maintenance capabilities.

Critical Provider Qualifications

Forklift-Specific Certification: Verify technicians possess current certifications from major forklift manufacturers including Toyota, Hyster, Crown, Raymond, and others relevant to your fleet composition.

Hydraulic System Expertise: Ensure service providers demonstrate specialized knowledge in forklift hydraulic systems, including complex multi-function valve bodies and precision lifting controls.

Battery Service Capabilities: For electric forklift fleets, confirm providers offer comprehensive battery services including reconditioning, charging system optimization, and replacement programs.

Parts Inventory Management: Assess the provider’s forklift parts inventory, including availability of critical components, OEM versus aftermarket options, and emergency sourcing capabilities.

Fleet Management Services: Evaluate additional services such as fleet tracking, maintenance scheduling, and performance reporting that optimize overall forklift operations.

Implementing Strategic Forklift Maintenance Programs

Successful forklift maintenance programs require systematic implementation tailored to specific operational requirements, fleet composition, and utilization patterns. Organizations must develop comprehensive approaches that address both immediate service needs and long-term asset management objectives.

Program Development Framework

Fleet Assessment and Analysis: Conduct thorough evaluation of current forklift condition, utilization patterns, maintenance history, and operational requirements to establish baseline performance metrics.

Customized Service Schedules: Develop maintenance intervals based on manufacturer recommendations, actual operating conditions, and historical performance data rather than generic schedules.

Performance Monitoring Systems: Implement tracking mechanisms to monitor forklift availability, service costs, safety incidents, and productivity metrics to measure program effectiveness.

Continuous Optimization: Regularly review maintenance outcomes and adjust service protocols based on performance data, technological advances, and changing operational needs.

Advanced Forklift Service Technologies

Telematics Integration: Modern forklift telematics systems provide real-time monitoring of equipment performance, utilization patterns, and maintenance requirements, enabling predictive service scheduling.

Condition-Based Monitoring: Advanced diagnostic tools monitor critical forklift systems continuously, alerting service providers to developing issues before failures occur.

Fleet Optimization Analytics: Sophisticated analysis of forklift performance data identifies opportunities for operational improvements, energy savings, and service optimization.

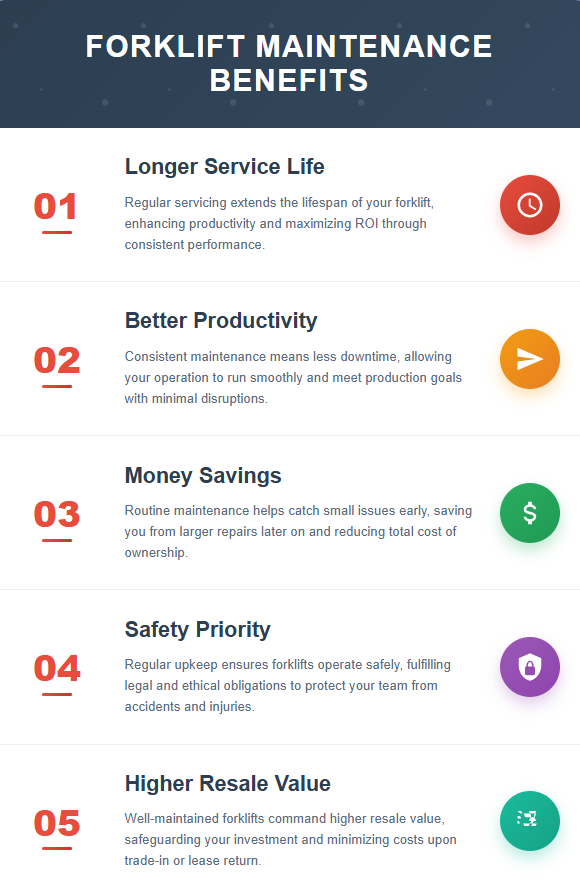

Return on Investment in Forklift Maintenance

Organizations implementing comprehensive forklift maintenance programs consistently achieve measurable returns through improved equipment availability, reduced emergency repairs, enhanced safety performance, and extended asset life.

Quantifiable Benefits

Increased Equipment Availability: Proactive forklift maintenance typically achieves 95-98% equipment availability compared to 85-90% for reactive approaches.

Reduced Total Cost of Ownership: Systematic maintenance programs reduce overall forklift operating costs by 15-25% through improved efficiency and extended equipment life.

Enhanced Safety Performance: Well-maintained forklifts experience significantly fewer safety incidents, reducing liability exposure and insurance costs.

Improved Productivity: Reliable forklift performance eliminates unexpected disruptions, enabling consistent achievement of productivity targets and delivery commitments.

Conclusion: Excellence Through Strategic Forklift Care

The distinction between operationally excellent and struggling facilities often centers on their approach to forklift maintenance and service. Organizations that recognize forklifts as critical business assets requiring specialized care consistently outperform those treating them as disposable equipment.

Implementing comprehensive forklift maintenance programs represents a strategic investment in operational reliability, safety performance, and long-term profitability. The specialized nature of forklift systems demands expert service providers with deep knowledge of hydraulic systems, battery technologies, and material handling applications.

For organizations committed to operational excellence, the path forward requires partnership with qualified forklift service specialists who understand the unique demands of material handling environments. This strategic approach will invariably result in improved equipment reliability, enhanced safety performance, and optimized total cost of ownership.

Success in modern material handling operations depends not merely on having forklifts, but on maintaining them with the specialized expertise they require. Organizations that embrace this philosophy position themselves for sustained competitive advantage through superior operational performance.