Have you ever watched a forklift operator effortlessly lift a pallet and wondered, “How much does a forklift weigh anyway?” I’ve observed somebody learned this the hard way when he assumed a forklift could fit on a regular truck trailer. Spoiler alert: it couldn’t, and that mistake cost us a delivery delay.

| Forklift Type | Typical Weight Range | Load Capacity | Best Use |

|---|---|---|---|

| Electric Indoor | 3,000 – 8,000 lbs | 3,000 – 6,000 lbs | Warehouse operations |

| Propane Standard | 8,000 – 10,000 lbs | 3,000 – 8,000 lbs | Mixed indoor/outdoor |

| Diesel Heavy-Duty | 15,000 – 140,000+ lbs | 10,000 – 100,000+ lbs | Heavy industrial work |

| Rough Terrain | 12,000 – 30,000 lbs | 5,000 – 25,000 lbs | Construction sites |

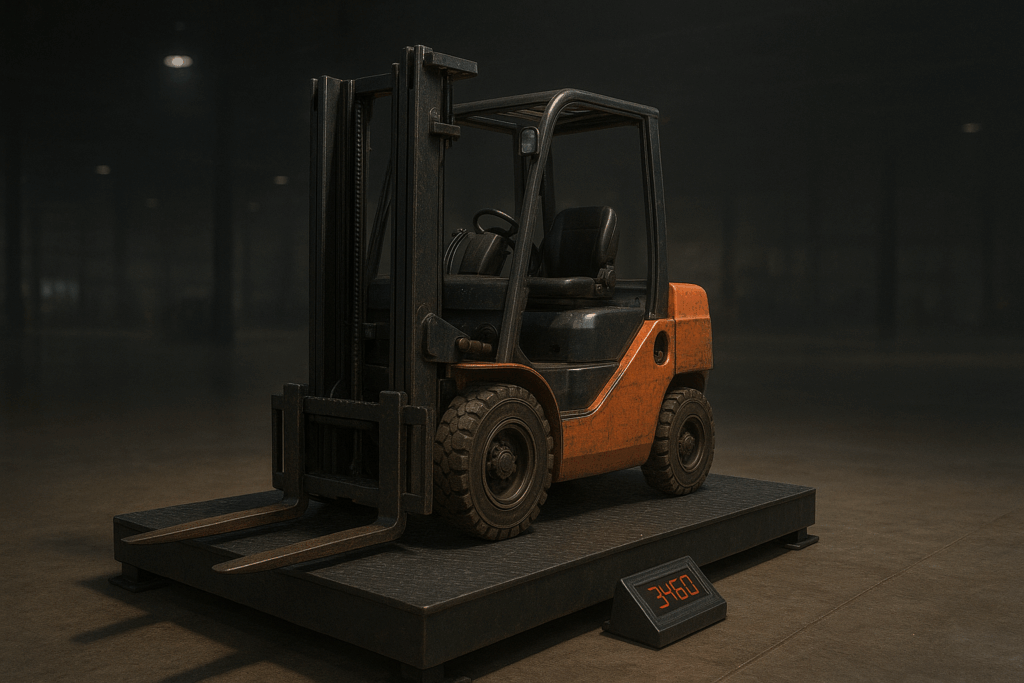

The average forklift weighs between 8,000 to 9,000 pounds – that’s roughly three times heavier than your car! This weight isn’t accidental; it’s engineered for stability and safety when lifting heavy loads.

Types of Forklifts and Their Weight Classifications

Electric Warehouse Forklifts

- Typically weigh 6,000-8,000 pounds for standard models

- Battery pack adds significant weight (1,500-3,000 lbs alone)

- Lighter overall than combustion engine counterparts

- Better weight distribution due to low center of gravity

- Perfect for smooth warehouse floors and tight spaces

I remember thinking electric forklifts would be lighter because they don’t have engines. Boy, was I wrong! The battery pack in these machines is basically a giant lead-acid powerhouse that can weigh as much as a small car.

Propane (LPG) Powered Forklifts

- Standard models: 8,000-10,000 pounds

- Propane tank adds 35-69 pounds when full

- Most common type in warehouses and distribution centers

- Good balance of power and maneuverability

- Can operate indoors and outdoors effectively

Diesel Engine Forklifts

- Range from 15,000 to over 140,000 pounds

- Heavier engines and fuel systems increase weight

- Built for demanding outdoor applications

- Exceptional lifting capacity for heavy loads

- Robust construction for harsh environments

Rough Terrain Forklifts

- Typically 12,000-30,000 pounds

- Reinforced frames and larger tires add weight

- Designed for construction and outdoor use

- Higher ground clearance affects center of gravity

- Variable reach models (telehandlers) can exceed 35,000 lbs

What Factors Determine How Much a Forklift Weighs?

Load Capacity Requirements

The lifting capacity directly influences forklift weight through several mechanisms:

- Counterweight design: Heavier loads require more counterweight

- Frame reinforcement: Higher capacities need stronger, heavier frames

- Hydraulic system size: More powerful hydraulics weigh more

- Mast construction: Taller, stronger masts add significant weight

| Capacity | Typical Forklift Weight |

|---|---|

| 3,000 lbs | 5,000 – 6,500 lbs |

| 5,000 lbs | 8,000 – 9,500 lbs |

| 8,000 lbs | 11,000 – 13,000 lbs |

| 15,000 lbs | 20,000 – 25,000 lbs |

| 30,000+ lbs | 35,000+ lbs |

Fuel Type and Power Systems

Electric Systems:

- Lead-acid batteries: 1,500-3,000 lbs

- Lithium-ion batteries: 20-30% lighter than lead-acid

- Electric motors are lighter than combustion engines

- No fuel tank weight fluctuation

Propane Systems:

- Engine weight: 500-800 lbs

- Propane tank: 35-69 lbs (empty to full)

- Fuel system components add 100-200 lbs

- Consistent weight regardless of fuel level

Diesel Systems:

- Heavy-duty engines: 1,000-2,500 lbs

- Fuel tank capacity: 15-50 gallons (additional 100-350 lbs when full)

- Cooling systems and exhaust components

- Reinforced engine mounts and frames

Mast Height and Design

Higher masts require additional structural support:

- 2-stage masts: Standard weight

- 3-stage masts: Add 300-500 lbs

- 4-stage masts: Add 600-800 lbs

- Quad masts: Can add 1,000+ lbs

- Telescoping masts: Heaviest option due to complex hydraulics

Weight Distribution and Stability Principles

The Counterweight Concept

Here’s where physics gets interesting (and why I failed to load that forklift properly years ago):

- Counterweight typically equals 1.5-2x the rated capacity

- Located at the rear of the forklift

- Balances loads carried on front forks

- Prevents tipping forward during lifting operations

- Made from cast iron or steel for maximum density

Real-world example: A 5,000 lb capacity forklift has approximately 7,500-10,000 lbs of counterweight. This explains why these machines are so surprisingly heavy!

Center of Gravity Considerations

- Forklift + load creates a stability triangle

- Weight distribution changes with load height

- Side-to-side stability depends on tire spacing

- Forward stability relies on counterweight effectiveness

- Improper loading can shift center of gravity dangerously

Forklift Weight Specifications by Popular Models

Toyota Models (Industry Standards)

- Toyota 7FBEU20: 6,180 lbs (4,000 lb capacity, electric)

- Toyota 8FGU25: 8,680 lbs (5,000 lb capacity, propane)

- Toyota 8FDU30: 11,200 lbs (6,000 lb capacity, diesel)

- Toyota 8TB50: 35,000 lbs (10,000 lb capacity, heavy-duty)

Hyster Popular Models

- Hyster J30XMT: 5,850 lbs (3,000 lb capacity, electric)

- Hyster H50FT: 9,100 lbs (5,000 lb capacity, propane)

- Hyster H80FT: 13,500 lbs (8,000 lb capacity, propane)

- Hyster H360HD: 45,000 lbs (36,000 lb capacity, diesel)

Crown Electric Forklifts

- Crown RC5500: 4,200 lbs (3,000 lb capacity)

- Crown FC5200: 6,800 lbs (5,000 lb capacity)

- Crown GPC3000: 5,500 lbs (6,000 lb capacity, counterbalance)

| Model Type | Weight Range | Capacity | Key Features |

|---|---|---|---|

| Compact Electric | 3,000-5,000 lbs | 1,500-3,000 lbs | Narrow aisles, indoor use |

| Standard Electric | 5,000-8,000 lbs | 3,000-6,000 lbs | General warehouse |

| IC Cushion Tire | 7,500-12,000 lbs | 3,000-8,000 lbs | Indoor/outdoor versatility |

| IC Pneumatic | 8,000-15,000 lbs | 5,000-15,000 lbs | Outdoor, rough surfaces |

| Heavy-Duty Diesel | 15,000-80,000+ lbs | 10,000-50,000+ lbs | Industrial applications |

Transportation and Logistics Considerations

Shipping Weight Implications

Getting forklifts delivered taught me some expensive lessons about weight limits:

- Standard truck trailers: 34,000 lb payload limit

- Low-boy trailers: Required for forklifts over 40,000 lbs

- Special permits: Needed for overweight/oversized loads

- Bridge restrictions: Some bridges have weight limits

- Fuel costs: Heavier equipment = higher shipping costs

Loading Dock Requirements

- Dock weight capacity: Must exceed forklift + maximum load

- Floor loading: Warehouse floors rated for point loads

- Ramp specifications: Grade limits based on forklift weight

- Overhead clearance: Mast height + safety margin

Storage and Facility Planning

- Floor reinforcement: May be needed for heavy forklifts

- Charging areas: Electric models need reinforced charging stations

- Fuel storage: Propane and diesel storage considerations

- Maintenance bays: Floor capacity for service work

Pro Tip from Experience

Always check your building’s floor load rating before bringing in heavy forklifts. I’ve seen warehouse floors crack under the concentrated weight of oversized equipment – it’s not pretty or cheap to fix.

Weight vs Performance Trade-offs

Advantages of Heavier Forklifts

- Superior stability: More counterweight = safer operation

- Higher capacity: Can handle heavier loads safely

- Better traction: More ground contact pressure

- Durability: Heavier construction typically lasts longer

- Outdoor capability: Weight helps with rough terrain stability

Disadvantages of Excessive Weight

- Floor loading concerns: May exceed building specifications

- Fuel consumption: Heavier machines use more energy

- Transportation costs: Expensive to ship and move

- Operator fatigue: Heavier steering and controls

- Infrastructure wear: More stress on docks and floors

Finding the Sweet Spot

The optimal forklift weight balances several factors:

- Load requirements: Match capacity to actual needs, not worst-case scenarios

- Operating environment: Indoor vs outdoor affects weight needs

- Facility limitations: Building and dock weight restrictions

- Operational efficiency: Heavier isn’t always better for productivity

- Total cost of ownership: Include transportation, fuel, and maintenance

Safety Considerations Related to Forklift Weight

Stability and Tipping Prevention

Understanding weight distribution prevents accidents:

- Load moment: Distance from mast × load weight

- Counterweight effectiveness: Decreases as load height increases

- Side stability: Depends on wheel base and center of gravity

- Dynamic forces: Acceleration and braking affect stability

- Attachments: Add-ons change weight distribution significantly

Operator Training on Weight Factors

Critical training points include:

- Capacity plate understanding: Never exceed rated limits

- Load positioning: Keep loads low and tilted back

- Speed limitations: Heavier loads require slower speeds

- Turning radius: Weight affects steering and stability

- Attachment compatibility: Each attachment has weight/capacity implications

Maintenance Weight Considerations

- Lifting equipment: Proper jacks and lifts for forklift weight

- Component replacement: Heavy parts require special handling

- Transportation to service: Getting broken forklifts to repair shops

- Parts inventory: Weight affects storage and handling of spare parts

Cost Implications of Forklift Weight

Initial Purchase Price Factors

Weight directly correlates with cost in several ways:

- Material costs: More steel and components = higher price

- Engineering complexity: Heavier models require more sophisticated design

- Manufacturing: Larger facilities and equipment needed for heavy models

- Shipping to dealer: Transportation costs built into price

Operating Cost Considerations

- Fuel/electricity consumption: Heavier machines use more energy

- Tire wear: More weight = faster tire degradation

- Maintenance frequency: Heavy-duty components need more service

- Facility costs: Reinforced floors and infrastructure requirements

Resale Value Factors

- Market demand: Common weights have better resale markets

- Transportation costs: Affect buyer willingness to pay

- Condition assessment: Weight affects wear patterns and evaluation

- Specialized applications: Very heavy models have limited buyers

| Weight Category | Purchase Cost | Operating Cost | Resale Value |

|---|---|---|---|

| Light (3,000-5,000 lbs) | Lower | Lower fuel/energy | Moderate |

| Standard (8,000-10,000 lbs) | Moderate | Balanced | Highest |

| Heavy (15,000-25,000 lbs) | Higher | Higher maintenance | Variable |

| Extra Heavy (25,000+ lbs) | Highest | Highest all costs | Limited market |

Common FAQs

How much does a standard warehouse forklift weigh?

A typical warehouse forklift with 5,000 lb capacity weighs between 8,000-9,000 pounds. This includes the counterweight, which makes up a significant portion of the total weight.

Why are forklifts so heavy compared to their lifting capacity?

Forklifts need substantial counterweight (typically 1.5-2x their capacity) to maintain stability when lifting loads. This counterweight, plus the robust frame and components, creates the surprisingly high total weight.

Do electric forklifts weigh more than propane models? Not necessarily.

Electric forklifts have heavy battery packs but lack engines and fuel systems. The weight difference is usually within 500-1,000 lbs, depending on the specific models compared.

Can my warehouse floor handle a heavy forklift?

Most modern warehouse floors can support standard forklifts (under 15,000 lbs), but you should verify the floor’s point load rating before bringing in heavy equipment. Older buildings may need reinforcement.

How does forklift weight affect transportation costs?

Heavier forklifts require larger trailers and may need special permits for overweight loads. Transportation costs can increase significantly for forklifts over 30,000 lbs due to specialized hauling requirements.

What’s the difference between operating weight and shipping weight?

Operating weight includes fluids, fuel, and sometimes attachments. Shipping weight is typically dry weight without fluids. The difference can be 200-500 lbs depending on fuel tank size and fluid capacities.

How much does the battery weigh in an electric forklift?

Electric forklift batteries typically weigh 1,500-3,000 lbs, representing 25-40% of the total forklift weight. Lithium-ion batteries can be 20-30% lighter than traditional lead-acid batteries.

Does forklift weight affect its lifting capacity?

Yes, there’s a direct relationship. Heavier forklifts generally have higher lifting capacities because they have more counterweight for stability. However, excessive weight without proper counterweight placement doesn’t help.

Can I modify a forklift to make it lighter?

Modifying forklift weight is dangerous and usually violates safety regulations. The weight is engineered for stability and safety. Any modifications should only be done by certified technicians with manufacturer approval.

How do I determine if my forklift is overweight for my application?

Check your facility’s floor load rating, dock capacity, and any bridge weight limits for your routes. Compare these limits to your forklift’s operating weight plus maximum load capacity for safe operation.

What’s the heaviest forklift ever made?

Industrial forklifts can exceed 140,000 lbs for specialized applications like steel mills and ports. Some container handling equipment technically classified as forklifts can weigh over 200,000 lbs.

How much does forklift weight affect fuel consumption?

Heavier forklifts typically consume 15-25% more fuel than lighter models with similar engines. The exact impact depends on operating conditions, load cycles, and efficiency of the power system.

Does the height of the mast affect forklift weight?

Yes, higher masts require additional structural support and hydraulic components. Each additional mast stage can add 300-800 lbs to the total forklift weight, affecting both stability and transportation requirements.

How accurate are manufacturer weight specifications?

Manufacturer weights are typically accurate within 2-3% for standard configurations. However, optional attachments, different tire types, or special configurations can add significant weight not reflected in base specifications.

Conclusion

Understanding how much a forklift weighs isn’t just academic curiosity – it’s critical for safe operation, proper facility planning, and smart purchasing decisions. From my years working with these machines, I’ve learned that weight affects everything from daily operations to long-term costs.

The key takeaway? A standard 5,000 lb capacity forklift weighs approximately 8,000-9,000 pounds, but this can vary dramatically based on type, fuel system, and intended application. Whether you’re buying your first forklift or managing a fleet, always consider the total weight implications for your specific situation.

Remember to verify your facility’s weight limits, plan for transportation requirements, and choose equipment that matches your actual needs rather than worst-case scenarios. The right forklift weight balance will serve your operation safely and efficiently for years to come.

Sources:

- U.S. Department of Labor, Occupational Safety and Health Administration. “Powered Industrial Trucks (Forklift) – Types & Fundamentals.” OSHA.gov, 2024.

- Conger Industries Inc. “How Much Does a Forklift Weigh? Understanding Forklift Weight.” February 6, 2025.

- CertifyMe. “How Much Does a Forklift Weigh? Forklift Weight & Load Capacity.” April 26, 2025.

- United Rentals. “Forklift Sizes: What to Know About Types, Capacities and Dimensions.” April 4, 2023.

- Toyota Material Handling. “Forklift Data Plate Reading Guide.” Toyota Forklifts Blog, 2024.