Key Features

Move Smarter with Modular Power.

Dematic’s Modular Conveyor System (MCS) offers flexible, scalable material handling by allowing easy reconfiguration without system replacement.

Its universal design supports efficient transport and integration with a wide range of warehouse technologies and load types.

- Easily modify or expand system without full replacement

- Universal side channel simplifies upgrades and module swaps

- Global metric design reduces spare part complexity

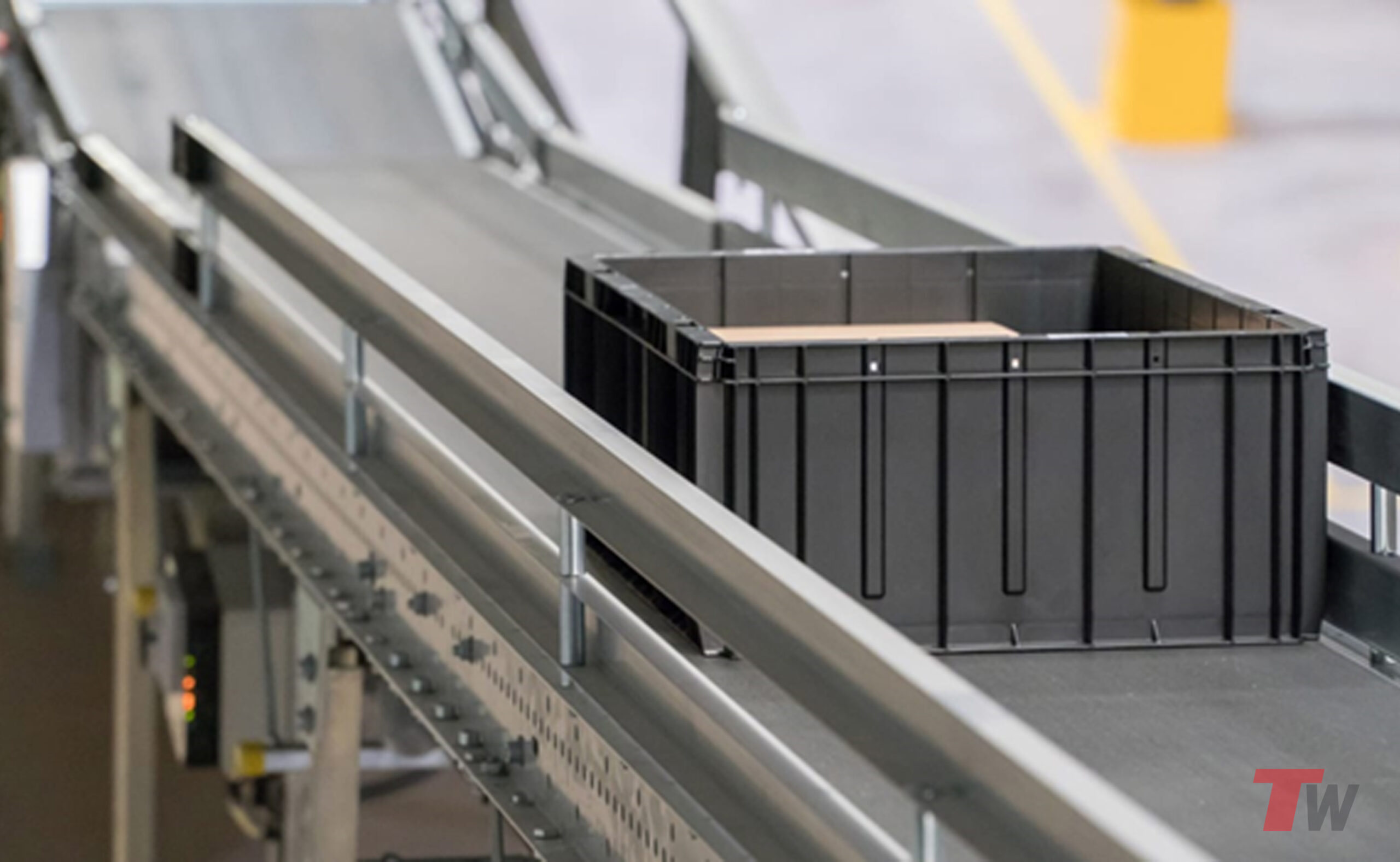

- Handles various load types: totes, trays, polybags, and parcels

- Integrates with scanners, printers, palletizers, robots, and more

Drive Smarter with Dematic MCS

Dematic MCS offers flexible drive options using AC motors, low-voltage motor-driven rollers, or both to optimize efficiency and reduce system costs.

Key features ensure quiet, precise, and reliable handling of various load types.

- AC motors for long, cost-effective runs

- Low-voltage rollers for modular control

- Quiet rollers with sealed bearings and spring action

- Vulcanized belts for stable carton handling

- Segmented belt conveyors with self-adjusting tracking

Seamless Sorting. Smarter Warehousing.

Dematic conveyor systems enhance warehouse efficiency by transporting, accumulating, and sorting products with precision.

Designed for seamless flow, they create optimal gaps and accurately divert items to their destinations.

- Versatile transport, accumulation, and sorting

- Precise gap creation and item diversion

- Seamless product flow across warehouse zones

- Supports strategic, high-throughput operations

- Enhances accuracy and operational speed

Engineered to Keep Goods Moving

Dematic Pallet Conveyor Systems efficiently move pallets, skids, tubs, and carts using integrated unit load technology, offering key functions such as transport, accumulation, diversion, rotation, and tilting.

Designed for seamless integration with AS/RS, palletizers, and stretch wrappers, they use standardized components and come in roller or chain formats.

- Transports various unit loads (pallets, tubs, carts)

- Offers accumulation, diversion, rotation, and tilting

- Seamlessly integrates with AS/RS and other systems

- Built with universal side channels and standardized parts

- Available in Roller and Chain configuration

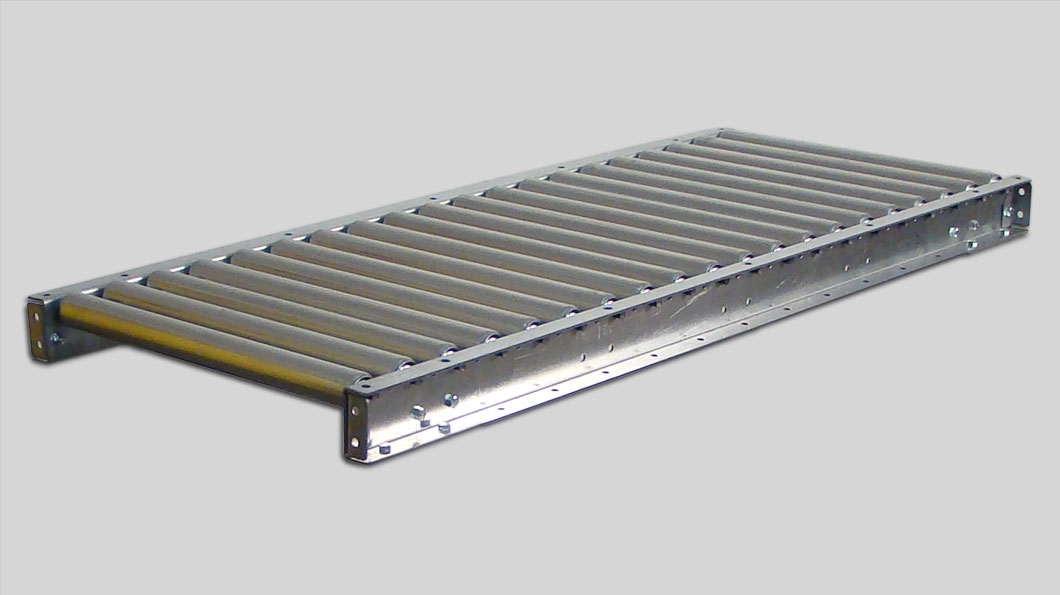

Roll Forward with Efficiency

Conveyor Roller Systems use cylindrical rollers to move goods efficiently, offering a durable, low-maintenance solution ideal for warehouses, distribution centers, and manufacturing.

Their modular, cost-effective design supports various layouts and integrates easily with broader material handling systems.

- Moves goods via powered or gravity-driven rollers

- Ideal for pallets, containers, and rigid packages

- Durable with low maintenance

- Works in straight, curved, or inclined paths

- Easily reconfigurable and scalable

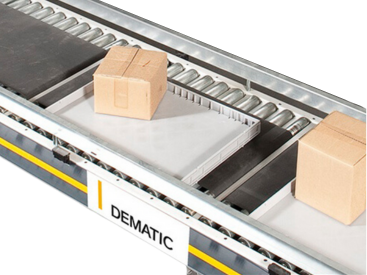

Smart Transport Starts with a Strong Belt.

Conveyor belt systems use a continuous moving belt to efficiently transport materials over varying distances and configurations.

Known for their versatility, they handle bulk or discrete items across industries, with options to customize for specific applications.

- Continuous belt spans between pulleys for smooth material transport

- Suitable for bulk and discrete handling

- Available in rubber, plastic, fabric, metal, or leather

- Customizable with guards, cleats, or coatings

- Energy-efficient and adaptable for horizontal, inclined, or vertical use

Air-Driven Precision for Sensitive Materials

Pneumatic conveyor systems use compressed air to transport dry bulk materials like powders and granules through enclosed pipes, offering superior cleanliness, containment, and routing flexibility.

Ideal for industries like food, pharma, and chemicals, they require minimal floor space and protect materials from contamination and environmental exposure.

- Enclosed transport prevents contamination

- Ideal for powders, granules, and dry bulk materials

- Flexible routing (vertical, horizontal, around obstacles)

- Space-saving design

- Supports multiple destinations with diverters and valve

Move More with Less

Gravity Conveyor Systems use a controlled decline to move goods without power, offering a cost-effective and energy-efficient solution for short-distance material handling.

Their simplicity, reliability, and ability to integrate with powered systems make them ideal for picking, shipping, and assembly areas.

- No power required – energy-efficient and cost-saving

- Ideal for short-distance movement (e.g., docks, packing stations)

- Simple design with minimal maintenance

- Reliable even during power outages

- Easily integrates with powered conveyors

Seamless Flow, Stronger Output

Automated conveyor systems help durable goods manufacturers move heavy components efficiently across production stages like cutting, welding, and assembly—reducing manual handling and labor costs.

With consistent material flow, these systems boost production speed, accuracy, and operational efficiency.

- Streamlines movement of WIP inventory

- Reduces manual handling and labor

- Enhances speed and accuracy

- Improves production consistency

- Optimizes overall operational efficiency

Precision Sorting for Every Parcel

Automated conveyor systems in parcel and postal operations streamline cross-docking by moving packages efficiently through sorting, packing, and loading.

With integrated barcode scanning, they reduce manual handling and accelerate delivery speeds.

- Streamlined inbound and outbound cross-docking

- Accurate sorting via barcode scanning

- Faster delivery times

- Reduced manual labor

- Efficient package routing through all processing stages

Warehousing Transport & Automation Specialists

Total Warehouse is your trusted specialist in Material Handling Automation Systems. With extensive experience, we create tailored solutions to address your unique business challenges. Powered by our partnership with Dematic, we deliver best-in-class solutions designed to optimize your warehouse operations.

Dematic Modular Conveyor

Flexible, Scalable, and Versatile

The Dematic Modular Conveyor features a universal metric side frame across all modules, making reconfiguration easy as operational needs evolve. With over 40 standard models, it supports a range of functions, including transportation, accumulation, gapping, and diverting—such as right-angle transfers and steerable wheel diverts. Available in multiple standard widths and configurations, the system offers horizontal, inclining, and declining sections, along with straight, curved, or angled junctions (wedges) to accommodate diverse material handling requirements.

Lease Rates

We can deliver the columbia journeyman today

Daily

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveWeekly

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveMonthly

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

Reservelong term

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveStill not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.