Dematic Automated Guided Vehicles

Smart Moves, No Support Legs.

Counterbalance AGVs are ideal for replacing manual forklift tasks, offering flexibility without support legs and handling a wide range of pallet applications. They’re perfect for repetitive transport, storage, and retrieval tasks across warehouse environments.

- No support legs needed due to rear counterweight

- Ideal for single, double, or quadruple pallet handling

- Automates repetitive forklift tasks

- Suitable for various storage systems (selective racking, drive-in, floor stacking)

- Supports product transfers, raw materials handling, and pallet replenishment

From Line to Warehouse, Seamlessly

Straddle AGVs automate repetitive forklift tasks with a compact design and tight turning radius, ideal for diverse warehouse layouts. They efficiently transport materials, handle multiple pallets, and streamline point-to-point operations.

- Replaces repetitive forklift tasks

- Handles multiple pallet types

- Operates in tight spaces

- Ideal for end-of-line transfers

- Supports production-to-warehouse transport

Precision Meets Performance at 33 Feet

High-Reach AGVs are built for high-bay racking systems, reaching up to 10 meters to handle storage and retrieval tasks. They offer a flexible, efficient alternative to fixed cranes in AS/RS environments and integrate easily with manual operations.

- Reach up to 10 meters for high-bay storage

- Suitable for both single-selective and double-deep racking

- Ideal for put-away and retrieval tasks

- Flexible alternative to fixed AS/RS cranes

- Seamless integration with manual operations

Navigate Narrow. Operate Big.

Very Narrow Aisle (VNA) AGVs are designed to operate efficiently in tight spaces between pallet racks, maximizing storage density. Their compact footprint allows businesses to reclaim valuable floor space and enhance operational flexibility.

- Operate efficiently in narrow aisles

- Maximize storage density

- Increase available floor space

- Improve operational flexibility

- Ideal for high-volume, space-constrained facilities

Heavy Loads, Handled Smartly.

Tugger AGVs are high-capacity, automated vehicles designed to pull carts loaded with materials across facilities, offering significantly more capacity than traditional forklifts. Ideal for manufacturing, they follow programmed routes to streamline the movement of heavy materials to and from assembly areas.

- Highest material transport capacity among AGV types

- Replaces traditional forklifts for bulk movement

- Supports both manual and automatic loading

- Ideal for long-distance or looped transport routes

- Enhances efficiency in manufacturing environments

Seamless Transfers. Smarter Operations.

Load Deck AGVs are designed to transport multiple unit loads between workstations, production areas, and warehouse zones, enhancing efficiency in material handling. They can be customized with various load-handling devices like roller conveyors, lift platforms, and shuttle systems to match operational needs.

- Transport 1–8 unit loads per trip

- Connect seamlessly with conveyors, palletizers, wrappers, and AS/RSs

- Support production and warehouse workflows

- Customizable load handling (rollers, belts, lifts, etc.)

- Ideal for end-of-line and inter-process automation

Compact Power, Maximum Productivity.

Compact Transfer AGVs are space-efficient vehicles designed for point-to-point material transport, ideal for tight spaces, narrow paths, and compact charging areas. Perfect for robotic cells and pick-and-go applications, they handle pallets efficiently and adapt well to production lines and conveyors.

- Operate in tight spaces with small turning radius

- Use lift or belt transfers based on load type

- Ideal for end-point delivery and pickup

- Integrate seamlessly with conveyors and robotic cells

- Support efficient pallet handling for pick & go workflows

From Specialty Tasks to Seamless Support

Custom Dematic AGVs are designed to meet unique operational needs while still using reliable, off-the-shelf components for ease of service. They’re ideal for specialized applications like retort processing, reel handling, and outdoor transfers.

- Tailored to specific business requirements

- Built with proven, serviceable components

- Supports unique workflows (retort, reels, containers)

- Handles complex or outdoor transfers

- Enhances operational flexibility and customization

Warehousing Transport & Automation Specialists

Total Warehouse is your trusted specialist in Material Handling Automation Systems. With extensive experience, we create tailored solutions to address your unique business challenges. Powered by our partnership with Dematic, we deliver best-in-class solutions designed to optimize your warehouse operations.

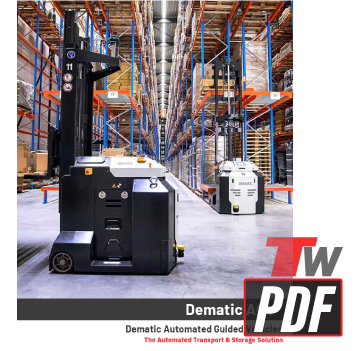

Dematic AGV's

Engineered to Move You Forward.

Dematic AGVs are flexible, safe, and efficient solutions for automating material handling across industries. Built with reliable components and smart software, they lift, move, and store goods with precision—reducing labor, damage, and costs. Seamlessly integrated with ERP/MES systems and designed for 24/7 use, they’re a scalable, future-ready tool for optimizing warehouse and production workflows.

Lease Rates

We can deliver the columbia journeyman today

Daily

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveWeekly

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveMonthly

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

Reservelong term

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveStill not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.