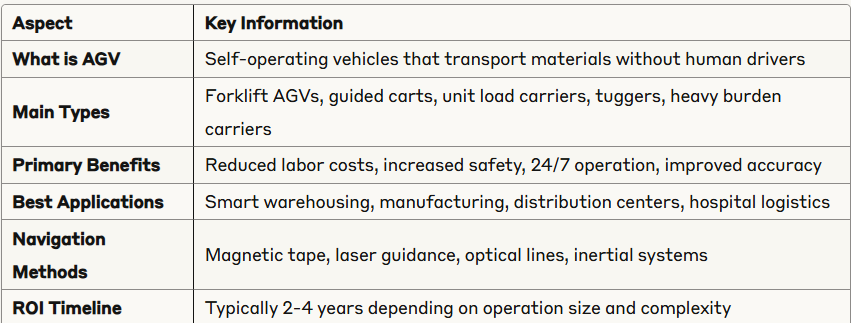

Key Takeaways: Everything You Need to Know About AGVs

AGVs represent one of the most practical advances in smart warehousing technology. These automated guided vehicle systems are basically self-driving vehicles that move stuff around without needing a person behind the wheel. Trust me, once you see them in action, you’ll wonder how warehouses ever functioned without them.

What is AGV Technology and Why It Matters

An automated guided vehicle (AGV) is essentially a mobile robot designed to transport materials, products, or equipment within controlled environments like warehouses and manufacturing facilities. I remember the first time I saw an agv robot in action – it was like watching magic happen on the warehouse floor.

The core purpose of AGVs is simple: replace human-operated vehicles like forklifts and manual carts with smart, automated systems. These agv robots follow predetermined paths and can handle repetitive material handling tasks with incredible precision.

Key Components of AGV Systems:

- Navigation system – Uses various guidance technologies

- Safety sensors – Detect obstacles and prevent collisions

- Communication modules – Connect to warehouse management systems

- Power systems – Usually battery-operated for continuous operation

- Load handling mechanisms – Forks, platforms, or specialized attachments

Types of Robots: Different AGV Categories for Smart Warehousing

Based on my experience implementing various automated guided vehicle systems, I’ve learned that choosing the right type of agv robot makes all the difference. Here are the main categories:

Automated Guided Carts (AGCs)

These are the simplest types of robots in the AGV family. I’ve deployed hundreds of these in assembly line operations because they’re perfect for lighter loads.

Common applications:

- Moving components between workstations

- Transporting tools and small parts

- Waste removal operations

- Hospital supply delivery

AGV Forklifts

AGV forklifts are probably what most people think of when they hear “automated guided vehicle.” These agv robots can lift, stack, and retrieve pallets just like traditional forklifts, but without a human operator.

I once worked with a client who replaced 12 forklift operators with 8 agv forklifts and saw their accuracy rate jump from 94% to 99.7%. The difference was remarkable.

| AGV Forklift Specs | Typical Range |

|---|---|

| Lifting Height | 6-40 feet |

| Load Capacity | 2,000-10,000 lbs |

| Operating Speed | 3-5 mph |

| Battery Life | 8-16 hours |

Unit Load AGVs

These automated guided vehicle systems are workhorses for pallet movement. They’re designed to transport individual unit loads like pallets, containers, or large racks.

Towing AGVs (Tuggers)

Think of these as train engines for your warehouse. Tugger agv robots pull multiple carts or trailers, making them incredibly efficient for moving multiple smaller loads simultaneously.

Heavy Burden Carriers

For the really big stuff – we’re talking about moving massive industrial components weighing several tons. I’ve seen these types of robots handle everything from aircraft parts to steel coils.

FAQ: What’s the difference between an AGV and a regular forklift? An AGV operates autonomously without a human driver, follows predetermined paths, and integrates with warehouse management systems for automated task assignment.

FAQ: Can AGV forklifts work in freezer environments? Yes, many agv forklifts are designed to operate in extreme temperatures, from -30°F freezers to high-temperature manufacturing environments.

How AGV Navigation Works in Smart Warehousing

The navigation system is the brain of any automated guided vehicle. After testing dozens of different guidance methods, I can break down the main approaches:

Magnetic Tape Navigation

This is old school but reliable. You literally stick magnetic tape on the floor, and the agv robot follows it like a bloodhound follows a scent trail.

Pros:

- Simple installation

- Cost-effective for basic routes

- Highly reliable

Cons:

- Limited flexibility

- Tape wear and tear

- Floor modifications needed

Laser Navigation Systems

This is where things get sophisticated. AGVs use laser scanners to detect reflectors positioned around the facility. I love this method because it’s incredibly precise.

Inertial Navigation

These systems use gyroscopes and accelerometers to track movement from known positions. Think of it as GPS for indoor environments.

| Navigation Method | Accuracy | Flexibility | Installation Cost |

|---|---|---|---|

| Magnetic Tape | High | Low | Low |

| Laser | Very High | Medium | Medium |

| Inertial | High | High | High |

Smart Warehousing Applications for AGVs

Smart warehousing is where AGVs really shine. I’ve implemented these systems across various industries, and the applications keep expanding.

Raw Material Transportation

AGVs excel at moving raw materials from receiving docks to storage areas or production lines. One manufacturing client saw their material flow time decrease by 40% after implementing automated guided vehicle systems.

Work-in-Process Movement

Moving partially completed goods through different production stages is perfect for agv robots. They maintain consistent timing and reduce handling damage.

Finished Goods Handling

Getting completed products from production to shipping areas safely and efficiently. AGVs eliminate the human error factor in this critical final step.

FAQ: How do AGVs integrate with existing warehouse management systems? Most modern AGVs connect via Wi-Fi or ethernet to WMS platforms, receiving real-time task assignments and reporting completion status automatically.

FAQ: What happens if an AGV breaks down during operation? Smart warehousing systems include redundancy planning – other AGVs can take over routes, and maintenance alerts prevent unexpected failures.

AGV Robot Safety and Obstacle Detection

Safety is huge when you’re dealing with automated guided vehicle systems. I’ve learned this the hard way – you can’t just plop these agv robots into an environment without proper safety measures.

Primary Safety Features:

- Lidar sensors – Create 360-degree awareness zones

- Ultrasonic sensors – Detect nearby obstacles

- Emergency stop buttons – Manual override capabilities

- Speed reduction zones – Automatically slow in pedestrian areas

- Audio/visual warnings – Alert nearby workers

The safety systems have gotten incredibly sophisticated. Modern agv robots can distinguish between a dropped box and a person, adjusting their response accordingly.

Benefits of Implementing AGVs in Smart Warehousing

After implementing dozens of automated guided vehicle projects, here are the real benefits I consistently see:

Cost Reduction Benefits:

- Labor cost savings – Reduce dependency on human operators

- Reduced product damage – Consistent handling reduces breakage

- Lower insurance costs – Fewer workplace accidents

- Energy efficiency – Electric AGVs cost less to operate than gas forklifts

Operational Improvements:

- 24/7 operation capability

- Consistent performance – No fatigue or sick days

- Data collection – Track every movement and optimize routes

- Scalability – Add more AGVs as operations grow

I worked with one distribution center that reduced their picking errors by 85% after implementing agv robots for material transport. The consistency is what really makes the difference.

| Benefit Category | Typical Improvement |

|---|---|

| Labor Costs | 30-50% reduction |

| Accuracy | 99%+ vs 95% manual |

| Operating Hours | 24/7 vs 16 hours |

| Safety Incidents | 75% reduction |

Challenges and Limitations of AGV Systems

Let me be honest about the downsides because I’ve dealt with them all:

Technical Limitations:

- Path dependency – AGVs need predetermined routes

- Dust sensitivity – Sensors require clean environments

- Limited flexibility – Can’t easily adapt to layout changes

- Space requirements – Need wider aisles than some alternatives

Implementation Challenges:

- High upfront costs – Significant initial investment

- Staff training – Teams need education on AGV operations

- System integration – Complex WMS connectivity requirements

- Maintenance expertise – Specialized technical knowledge needed

The biggest mistake I see companies make is underestimating the infrastructure changes needed for successful AGV implementation.

FAQ: How much space do AGVs need compared to human-operated equipment? AGVs typically require 10-20% wider aisles than manual equipment to accommodate their safety sensors and navigation systems.

FAQ: What maintenance is required for AGV systems? Regular sensor cleaning, battery maintenance, software updates, and periodic navigation recalibration are the main requirements.

AGV vs Alternative Technologies

Smart warehousing offers several automation options beyond AGVs. Here’s how they compare:

AGVs vs Conveyor Systems

Conveyors are fixed-path systems while AGVs are mobile. Conveyors handle higher throughput but AGVs offer more flexibility.

AGVs vs Autonomous Mobile Robots (AMRs)

AMRs are more advanced – they create their own maps and navigate dynamically. AGVs follow predetermined paths. AMRs cost more but adapt better to changing environments.

AGVs vs AS/RS Systems

Automated Storage and Retrieval Systems combine storage and transport. AS/RS systems use 75% less floor space than AGV-based systems but cost significantly more upfront.

| Technology | Flexibility | Throughput | Space Efficiency | Cost |

|---|---|---|---|---|

| AGVs | Medium | Medium | Medium | Medium |

| Conveyors | Low | High | Low | Low |

| AMRs | High | Medium | Medium | High |

| AS/RS | Low | High | Very High | Very High |

Implementation Best Practices for AGV Projects

Based on my project experience, here’s what actually works:

Planning Phase:

- Conduct detailed workflow analysis – Map every material movement

- Calculate ROI scenarios – Include all costs and benefits

- Plan infrastructure modifications – Floor markings, charging stations

- Design redundancy – Plan for equipment failures

Installation Phase:

- Start with pilot areas – Prove the concept before full deployment

- Train operators thoroughly – Both technical and safety aspects

- Test safety systems extensively – Better safe than sorry

- Document everything – Create detailed operational procedures

Optimization Phase:

- Monitor performance metrics – Track efficiency improvements

- Adjust routes based on data – Optimize for actual usage patterns

- Regular maintenance scheduling – Prevent unexpected downtime

- Continuous staff training – Keep everyone updated on best practices

Future of AGVs in Smart Warehousing

The agv robot technology keeps evolving. Here’s what I’m seeing on the horizon:

Emerging Technologies:

- AI-powered route optimization – Real-time path planning

- Advanced sensor fusion – Better environmental awareness

- Wireless charging – Eliminate charging downtime

- 5G connectivity – Faster, more reliable communication

Market Trends:

- Smaller, more agile AGVs – Better for tight spaces

- Collaborative robots – Work safely alongside humans

- Cloud-based fleet management – Remote monitoring and control

- Predictive maintenance – AI prevents failures before they happen

I believe we’ll see AGVs become as common as forklifts within the next decade, especially in smart warehousing applications.

AGV Integration with Existing Systems

Getting automated guided vehicle systems to play nice with existing warehouse technology is critical. I’ve seen too many projects fail because of poor integration planning.

Key Integration Points:

- Warehouse Management Systems (WMS) – Task assignment and tracking

- Enterprise Resource Planning (ERP) – Inventory and order management

- Transportation Management Systems (TMS) – Shipping coordination

- Building Management Systems – Door controls and environmental systems

Common Integration Challenges:

- Data format compatibility – Different systems speak different languages

- Real-time communication – Ensuring instant data updates

- System reliability – One failure shouldn’t stop everything

- Security protocols – Protecting against cyber threats

FAQ: How long does AGV system integration typically take? Most implementations take 3-6 months from planning to full operation, depending on system complexity and facility size.

FAQ: Can AGVs work with existing barcode systems? Yes, AGVs can be equipped with barcode scanners and integrate with existing inventory tracking systems seamlessly.

Cost Analysis and ROI Calculations

Let me break down the real costs because this is where many projects succeed or fail:

Initial Investment Costs:

- AGV hardware – $25,000-$100,000+ per unit

- Infrastructure modifications – Floor prep, charging stations

- Software licensing – WMS integration and fleet management

- Training and implementation – Staff education and system setup

Ongoing Operational Costs:

- Maintenance contracts – Typically 10-15% of hardware cost annually

- Energy costs – Usually 60-80% less than gas-powered equipment

- Software updates – Regular feature enhancements

- Operator training – Ongoing education for staff

ROI Calculation Factors:

- Labor cost savings – Reduced headcount or redeployment

- Productivity improvements – Faster material movement

- Accuracy gains – Reduced errors and rework

- Safety benefits – Lower insurance and accident costs

| Cost Category | Year 1 | Year 2-5 | Total 5-Year |

|---|---|---|---|

| Initial Investment | $500K | $0 | $500K |

| Annual Operating | $75K | $75K/year | $375K |

| Annual Savings | $200K | $200K/year | $1,000K |

| Net ROI | 25% | 167% | 125K net gain |

Training and Change Management

The human element is often the trickiest part of AGV implementation. I’ve learned that success depends as much on people as technology.

Staff Training Components:

- Safety procedures – Working around automated equipment

- System operation – Basic AGV interaction and monitoring

- Troubleshooting – Identifying and resolving common issues

- Emergency procedures – Handling system failures or accidents

Change Management Strategies:

- Early involvement – Include staff in planning discussions

- Clear communication – Explain benefits and address concerns

- Gradual implementation – Phase in AGVs rather than wholesale replacement

- Continuous feedback – Regular check-ins and adjustments

One thing I always tell clients: your existing warehouse staff are your best resource for optimizing AGV operations. They know the workflow better than anyone.

FAQ: How do workers typically react to AGV implementation? Initial skepticism is common, but most workers appreciate the reduced physical strain and ability to focus on higher-value tasks once they see the benefits.

FAQ: What skills do employees need to work with AGVs? Basic computer literacy, safety awareness, and problem-solving skills are most important. Technical expertise isn’t required for daily operations.

Maintenance and Troubleshooting

Keeping AGVs running smoothly requires a structured approach. Here’s what I’ve learned from managing hundreds of these systems:

Preventive Maintenance Schedule:

- Daily checks – Battery levels, sensor cleaning, visual inspection

- Weekly maintenance – Software updates, detailed sensor calibration

- Monthly services – Mechanical component inspection, performance analysis

- Annual overhauls – Complete system evaluation and upgrades

Common Issues and Solutions:

- Navigation errors – Usually sensor cleaning or recalibration

- Battery problems – Monitoring charge cycles and replacement timing

- Communication failures – Network connectivity troubleshooting

- Mechanical wear – Bearing, wheel, and motor maintenance

Troubleshooting Best Practices:

- Remote diagnostics – Monitor systems from central control

- Predictive analytics – Identify problems before failures occur

- Spare parts inventory – Keep critical components in stock

- Technical support contracts – 24/7 vendor support for complex issues

Real-World Case Studies and Lessons Learned

Let me share some actual implementations I’ve been involved with:

Case Study 1: Automotive Parts Distribution

Challenge: 500,000 sq ft facility needed to reduce picking errors and increase throughput Solution: 15 unit load AGVs with laser navigation Results:

- 45% reduction in picking errors

- 30% increase in daily throughput

- ROI achieved in 28 months

- Key lesson: Start with high-volume, repetitive routes for best results

Case Study 2: Pharmaceutical Manufacturing

Challenge: Strict contamination control requirements in clean room environment Solution: 8 specialized AGVs with sealed electronics and easy-clean surfaces Results:

- Zero contamination incidents

- 60% reduction in material handling labor

- Compliance with FDA requirements maintained

- Key lesson: Industry-specific modifications are worth the extra investment

Case Study 3: E-commerce Fulfillment

Challenge: Seasonal volume fluctuations and tight delivery windows Solution: Hybrid AGV/manual system with scalable fleet Results:

- 200% peak season capacity increase

- Maintained service levels during volume spikes

- 25% reduction in temporary labor costs

- Key lesson: Flexibility is crucial for seasonal businesses

Conclusion: Making Smart Warehousing Decisions About AGVs

After years of implementing automated guided vehicle systems, I can say with confidence that AGVs are transforming smart warehousing operations. These agv robots offer tremendous benefits for the right applications, but they’re not a magic bullet for every situation.

The key is matching the technology to your specific needs. If you have predictable, repetitive material handling tasks in a controlled environment, AGVs can deliver exceptional ROI. If your operations are highly variable or space-constrained, you might want to consider alternatives like AS/RS systems or AMRs.

Remember these critical success factors:

- Thorough planning – Map your workflows and calculate realistic ROI

- Proper integration – Ensure AGVs work with existing systems

- Staff buy-in – Include your team in the planning process

- Gradual implementation – Start small and scale up

- Ongoing optimization – Continuously improve based on performance data

The future of smart warehousing will definitely include more automation, and AGVs are a proven stepping stone toward fully automated facilities. Whether you choose agv forklifts, guided carts, or other types of robots, the most important thing is to start with a clear understanding of your goals and constraints.