Key Takeaways:

- Implement a logical flow system and use vertical space effectively

- Use FIFO method and regular stock counts for inventory management

- Maintain cleanliness with a regular schedule and 5S system

- Ensure safety through proper training, signage, and equipment maintenance

- Optimize space with appropriate storage solutions and technology implementation

- Utilize Warehouse Management Systems (WMS) and data analytics for efficiency

Hey there, fellow warehouse warriors! Today, we’re diving into the world of warehouse maintenance. Trust me, I’ve seen my fair share of chaotic warehouses, and let me tell you, it ain’t pretty. But don’t worry, I’ve got your back with some essential guide lines for maintaining warehouse space that’ll help you keep your warehouse running smoother than a freshly oiled conveyor belt.

Did you know that poor warehouse management can lead to a 20-30% decrease in operational efficiency? Yikes! That’s like throwing money straight into the dumpster. But here’s the thing: maintaining a warehouse isn’t just about keeping things tidy (though that’s important too). It’s about creating a well-oiled machine that’ll make your life easier and your boss happier.

Organizing Your Warehouse Layout

Here are the summarization of key elements to consider when organizing your warehouse layout:

Alright, let’s talk about organizing your warehouse layout. This is where the magic happens, folks! A well-organized warehouse is like a beautiful dance – everything just flows.

First things first, you need implement a logical flow system. Think about it like this: you want your warehouse to be as smooth as your favorite dance move (mine’s the robot, in case you’re wondering). Start by mapping out the most common paths your products take from receiving to shipping. Then, arrange your storage areas and workstations along these paths. Trust me, this’ll save you more steps than a fitness tracker!

Now, let’s talk about using vertical space effectively. I once worked in a warehouse where we only used about half of our vertical space. What a waste! It was like having a two-story house but only living on the ground floor. Don’t make the same mistake I did. Invest in some good quality pallet racks or shelving units that reach all the way up to the ceiling. Just make sure you’ve got the right equipment to reach those top shelves safely!

Creating designated areas for different activities is crucial too. You wouldn’t want your packing station right next to your receiving area, would you? That’s a recipe for chaos, my friend. I learned this the hard way when I accidentally shipped out a bunch of empty boxes because our packing and receiving areas were too close together. Talk about a facepalm moment!

Lastly, don’t forget about optimizing your aisle width and pallet rack configuration. You want your aisles wide enough for your equipment to move through safely, but not so wide that you’re wasting space. It’s a delicate balance, like trying to fit into your favorite jeans after Thanksgiving dinner.

Remember, organizing your warehouse layout isn’t a one-and-done deal. You need to be willing to shake things up if something’s not working. Be flexible, be creative, and don’t be afraid to try new things. Your perfect layout is out there, I promise!

Inventory Management Strategies

Alright, buckle up buttercup, we are about to dive into the wild world of inventory management. This is where the rubber meets the road in warehouse maintenance, and let me tell you, I’ve seen some inventory nightmares that’d make your hair stand on end.

Key Inventory Management Strategies:

- Implement a robust inventory tracking system

- Use barcode or RFID technology

- Account for every item coming in or going out

- Avoid lost inventory nightmares

- Use the FIFO (First-In-First-Out) method

- Crucial for perishable goods

- Organize storage areas with older stock at the front

- Prevent expired product shipments

- Conduct regular stock counts and audits

- Catch discrepancies early

- Treat it like a check-up for your warehouse

- Opportunity to discover hidden inventory issues

- Optimize reorder points and safety stock levels

- Balance demand with inventory levels

- Avoid drowning in excess stock

- Show off your inventory management skills

Remember, good inventory management is all about staying on top of things. It might seem like a pain in the rear now, but trust me, it’ll save you a world of headaches down the road. And who knows? You might even start to enjoy it. Stranger things have happened!

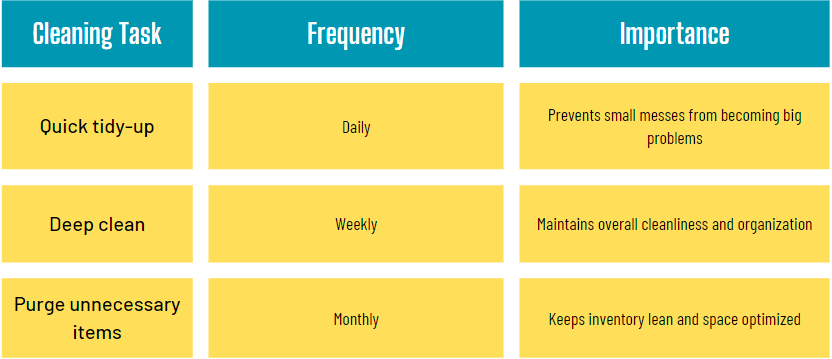

Maintaining Cleanliness and Order

Alright, folks, let’s roll up our sleeves and dive into the glamorous world of warehouse cleanliness and order. I know, I know, it’s not exactly the hottest topic, but trust me, a clean warehouse is a happy warehouse.

Next up, let’s talk about implementing a 5S system. It’s like Marie Kondo for your warehouse!

The 5S System:

- Sort: Get rid of what you don’t need

- Set in order: Organize what’s left logically

- Shine: Clean everything thoroughly

- Standardize: Create consistent processes

- Sustain: Maintain your efforts long-term

Now, let’s chat about proper waste management and recycling procedures. This isn’t just about being eco-friendly (although that’s important too). It’s about keeping your warehouse clean and safe.

Waste Management Tips:

- Designate specific areas for different types of waste

- Ensure everyone knows proper disposal procedures

- Don’t let cardboard pile up by the baler (trust me on this one!)

- Address spills and damages immediately for safety

Remember, maintaining cleanliness and order isn’t a one-time thing. It’s an ongoing process that requires commitment from everyone in the warehouse. But hey, look on the bright side – at least you’re getting your steps in while you clean!

Ensuring Warehouse Safety

Alright, folks, it’s time to talk about something that’s near and dear to my heart – warehouse safety. Now, I know what you’re thinking. “Safety? Boooring!” But let me tell you, after spending years in this industry and seeing my fair share of close calls, I can assure you that safety is anything but boring.

Key Safety Measures:

- Regular equipment maintenance and inspections

- Stick to maintenance schedules religiously

- Prevent unexpected breakdowns

- Avoid disruptions during busy seasons

- Proper training for ALL staff members

- Include office workers who rarely visit the warehouse floor

- Cover safety protocols for every role

- Prevent accidents due to lack of knowledge

- Clear signage and floor markings

- Think of them as road signs for your warehouse

- Guide people on where to go (and where not to go)

- The more visible, the better!

- Comprehensive safety protocol

- Cover everything from proper lifting techniques to emergency procedures

- Make it your warehouse’s constitution

- Regularly review and update as needed

Remember, safety isn’t just about following rules. It’s about creating a culture where everyone looks out for each other. It’s about being able to go home at the end of the day in the same condition you came in. And hey, if you can do all that while still having a bit of fun, then you’re doing it right!

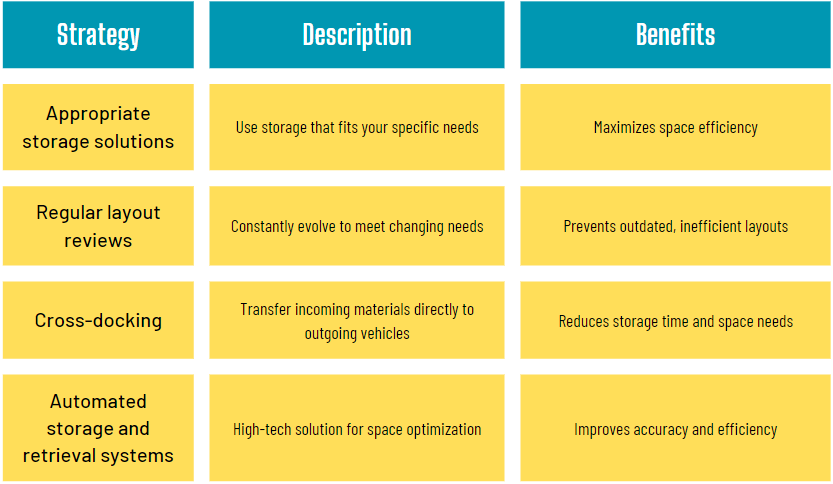

Guidelines for Optimizing & Maintaining Space Utilization

Alright, space cadets, it’s time to talk about one of my favorite topics – optimizing space utilization in your warehouse. Now, I know what you’re thinking. “But Jim, my warehouse is already packed tighter than a can of sardines!” Well, buckle up buttercup, because I’m about to blow your mind with some space-saving strategies that’ll make you feel like you’ve discovered a whole new dimension.

Space Optimization Strategies:

Remember, optimizing your space isn’t just about cramming more stuff in. It’s about making the most of what you’ve got. It’s like playing a real-life game of Tetris, but instead of lines disappearing when you complete them, you get a more efficient warehouse. And trust me, that’s way more satisfying!

Implementing Technology for Efficiency

Alright, now it’s time to geek out over some warehouse technology! Now, I know some of you old-school warehouse managers might be breaking out in a cold sweat at the mere mention of new tech. But trust me, embracing technology in your warehouse is like discovering fire – it’ll change your life!

Key Warehouse Technologies:

- Warehouse Management Systems (WMS)

- Acts as the brain of your operation

- Tracks inventory, processes orders, manages shipping schedules

- Like having a super-smart, tireless assistant

- Barcode and RFID technology

- Barcode: Reliable workhorse for inventory tracking

- RFID: Flashy newcomer with impressive capabilities

- Dramatically reduces errors in data entry

- IoT sensors for environmental monitoring

- Track temperature, humidity, light levels

- Catch issues before they cause damage

- Like having tiny meteorologists throughout your warehouse

- Data analytics for performance optimization

- Spot trends and identify bottlenecks

- Make data-driven decisions

- Optimize operations like picking routes

Remember, implementing new technology isn’t about replacing your workforce – it’s about empowering them. It’s about giving them the tools they need to work smarter, not harder. And hey, who doesn’t want to feel like they’re working in a warehouse of the future?

Conclusion

Whew! We’ve covered a lot of ground today, haven’t we? From organizing your layout to implementing cutting-edge technology, we’ve explored the A to Z of maintaining an efficient warehouse space. But here’s the thing – there’s no one-size-fits-all solution. Every warehouse is unique, with its own quirks and challenges.

Key Takeaways:

- Customize these guidelines to fit your specific needs

- Warehouse optimization is an ongoing process

- Prioritize safety and ethical considerations

- Use technology responsibly, especially regarding data and privacy

Now, I want to hear from you! What challenges are you facing in your warehouse? What tips and tricks have you discovered that make your job easier? Share your experiences in the comments below. After all, we’re all in this together, and the best way to improve is to learn from each other.

So go forth, warehouse warriors! Armed with these guidelines, you’re ready to transform your warehouse into a lean, mean, storing machine. And remember, if you ever feel overwhelmed, just take it one pallet at a time. You’ve got this!

About the Author:

Dom is an engineering manager at Total Warehouse with extensive experience in optimizing warehouse spaces and designing innovative pallet racking systems. With a career spanning over 8 years, he has successfully led cross-functional teams to implement solutions that improve operational efficiency and maximize storage capacity. Known for his expertise in lean manufacturing principles and warehouse automation, Dom has delivered projects that not only reduce costs but also enhance safety and workflow. With a proven track record in both design and execution, Dom is a trusted expert in warehouse optimization.