Your racking system is the backbone of your warehouse—and like any core infrastructure, it requires regular inspection and maintenance to stay safe, efficient, and compliant. Over time, even the best-installed systems can suffer wear, impact damage, or anchoring failures. Ignoring these signs can lead to serious safety risks, costly downtime, and non-compliance with OSHA and RMI standards.

At Total Warehouse, we specialize in pallet rack inspections, structural evaluations, and expert repair services designed for the real-world demands of distribution centers and high-traffic storage facilities. Based in Anaheim, CA, we also bring specialized expertise in seismic rack inspections for businesses operating throughout the West Coast.

When Do You Need a Professional Rack Inspection?

Not every issue is visible to the untrained eye. If your warehouse is experiencing any of the following, it’s time to schedule a professional inspection:

- A forklift has struck a rack

- Racking has been modified or reconfigured

- Load weights have changed or increased

- Anchors are visibly missing, loose, or sheared

- Beams or uprights appear bent or misaligned

- Monthly internal walkthroughs reveal signs of wear

- Your facility is preparing for an OSHA audit or certification

Even seemingly minor rack damage—like a slightly twisted upright or bent footplate—can reduce the system’s load capacity and compromise safety. That’s why industry standards recommend annual inspections by a certified racking professional, along with more frequent checks for high-volume operations.

What Our Rack Inspection Services Include

Our expert team uses a proven multi-step process to ensure nothing is missed:

- Structural Integrity Check – We evaluate uprights, beams, braces, and anchors for stress, deformation, or wear.

- Connection Review – Beam locking mechanisms, safety pins, and anchor points are inspected for proper installation and security.

- Load Labeling and Compliance – We verify that load capacities are clearly marked and align with current inventory and system specs.

- Floor Conditions and Baseplates – A close review of baseplates, floor leveling, and anchoring integrity ensures the system is stable from the ground up.

- Damage Report and Repair Plan – After inspection, we deliver a detailed report with repair recommendations, safety risks, and next steps to restore system compliance.

All inspections are performed in accordance with RMI (ANSI MH16.1) guidelines, as well as OSHA 1910.176(b) safety standards.

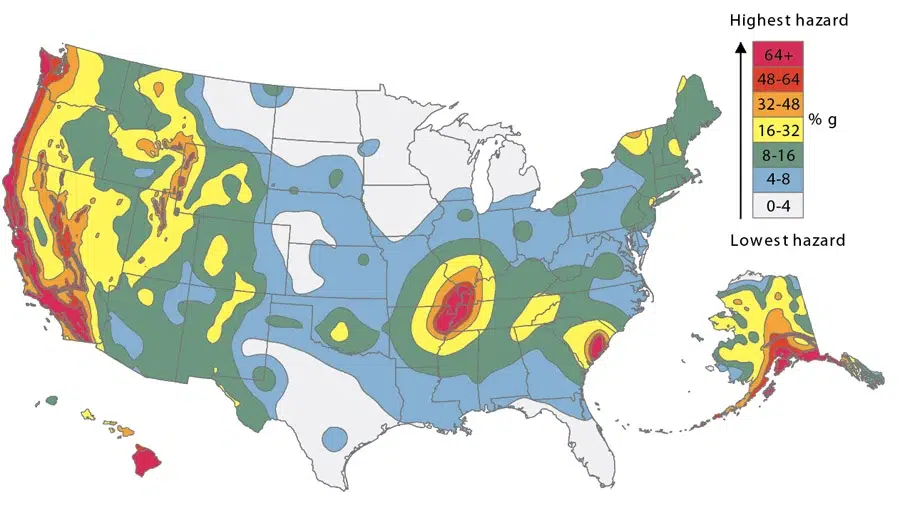

Seismic Rack Inspections: West Coast Expertise

For warehouses located in California and other seismic-prone areas, racking systems must meet additional structural and anchoring requirements to withstand potential earthquake activity. This is especially important in cities like Los Angeles, Anaheim, San Diego, and San Francisco, where seismic risk is higher.

Total Warehouse offers specialized seismic racking inspections designed to:

- Evaluate current rack systems for seismic zone compliance

- Ensure seismic footplates and anchor bolts meet California building code requirements

- Identify stress points that may fail under lateral force

- Prepare facilities for permitting and regulatory approval during retrofits or build-outs

Our Anaheim-based team has decades of experience helping clients navigate California’s seismic engineering requirements for storage racking. Whether you’re expanding your facility, upgrading old systems, or pursuing seismic recertification, we can help you ensure your racking meets code and keeps your operation protected.

When Repairs Are the Right Move

Rack repairs can often be completed faster and more cost-effectively than full replacements—especially when only select components are damaged. We offer custom rack repair solutions including:

- Upright reinforcement and replacement

- Brace and footplate repairs

- Anchor bolt reinstallation or upgrade

- Structural retrofits for seismic zones

- Rack guard installation for impact protection

All repair components are built to spec, restoring your system to its original load rating while minimizing downtime.

Why Choose Total Warehouse?

With over 25 years in the industry, Total Warehouse brings a comprehensive, consultative approach to warehouse safety. We don’t just flag issues—we partner with you to design smart, durable solutions that protect your team and inventory long-term.

Clients across the West Coast rely on us for:

- Certified rack inspections

- OSHA and RMI compliance assessments

- Seismic and structural rack evaluations

- Professional on-site repairs and retrofits

- End-to-end project support for upgrades and reconfigurations

We offer free site assessments, fast turnaround on quotes, and expert guidance from our Southern California-based team.

Schedule Your Rack Safety Assessment

If your racking system hasn’t been professionally inspected in over a year—or you’ve recently experienced damage, growth, or layout changes—now is the time to act.

Contact Total Warehouse today to schedule your free rack inspection or consultation. Our team will assess your system, identify vulnerabilities, and provide a clear path toward restoring full safety and compliance.

Your storage system deserves more than a patchwork fix. Let’s protect your operation with expert service you can trust.