Linde Forklifts vs. Toyota Forklifts vs. Hyster Forklifts

In the material handling equipment industry, businesses often weigh the merits of leading forklift brands: Toyota, Hyster, and Linde. While Toyota and Hyster have established reputations, Linde forklifts, a subsidiary of the KION Group, offer distinctive advantages that cater specifically to the dynamic needs of U.S. industries.

In this comparison, we’ll break down the key features and differences between Linde Forklifts, Toyota Forklifts, and Hyster Forklifts to help you make an informed decision for your warehouse operations.

Linde Forklifts vs Toyota Forklifts vs Hyster Forklifts

1. Efficiency and Productivity

Linde Forklifts

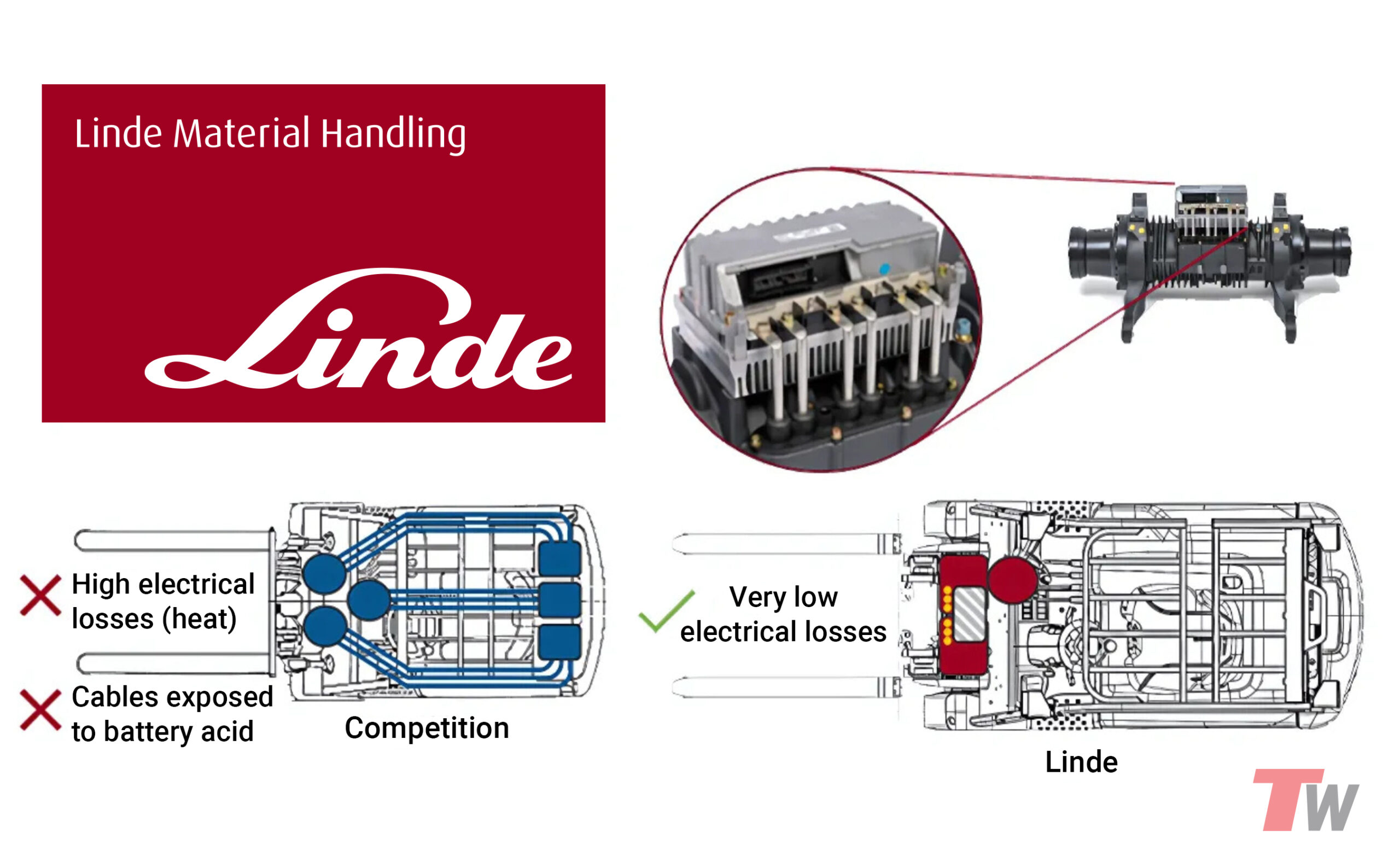

- Hydrostatic Drive System: Linde’s proprietary hydrostatic drive system delivers smooth, precise control over speed and direction, reducing wear and tear on components. This system ensures optimal productivity, especially in high-intensity operations.

- Modular Design: Linde’s modular concept allows for customization, enabling businesses to adapt the forklift to specific needs, further enhancing efficiency.

- Lower Fuel Consumption: Linde forklifts are designed to minimize fuel consumption (up to 40-50% less fuel) with hydrostatic drive, reducing operational costs over time.

Toyota Forklifts

- AC Drive Systems: Toyota’s AC drive systems are efficient but lack the precision and smoothness of others’ hydrostatic drives.

- Focus on Reliability: Toyota forklifts are known for their reliability, but fall behind in quality and innovative technologies such as hydrostatic drive system and modular design

Hyster Forklifts

- Variable Power Technology: Hyster forklifts offer customizable performance options that allow users to adjust performance modes.

- Lower Fuel Consumption: Lower fuel consumption with on-demand hydraulics and customizable performance modes.

Comparison

Linde’s hydrostatic drive system and modular design give it a clear edge in efficiency and productivity, making it ideal for businesses looking to maximize output.

2. Ergonomics and Operator Comfort

Linde Forklifts

- Ergonomic, Multifunction Control Handle: Engineered with an intuitive shape, angle, and grip, Linde’s control handle minimizes wrist and arm strain, allowing operators to work more comfortably for extended periods.

- Linde Load Control System: Enables seamless, fingertip control of all hydraulic functions, reducing effort and improving precision—especially important for repetitive material handling tasks.

- Intelligent Suspension System: Absorbs shocks and vibrations, even on uneven warehouse surfaces, resulting in a smoother, quieter ride and less physical strain on the operator.

- Suspended Operator Compartment: Isolated from chassis vibrations, this feature enhances ride comfort and minimizes fatigue during long shifts.

- Spacious Cab with Adjustable Components: Linde cabs are built around the operator, featuring adjustable armrests, seats, and steering columns to suit different body types and postures.

- Maintenance-Free Components: Systems such as sealed brakes and hydrostatic drives reduce maintenance needs and unscheduled downtime, keeping operators on the job and reducing workplace frustration.

Toyota Forklifts

- Suspension Seats: Improves comfort by absorbing floor vibration, but does not address full-body ergonomics or control efficiency.

- Good Sight Lines: Prioritizes safety through improved mast visibility, contributing to situational awareness but not directly enhancing physical comfort.

- Traditional Cab Design: Functional but lacks the adaptive elements and SP ergonomic layout of Linde’s operator-centric approach.

Hyster Forklifts

- Spacious Cab Design: Offers more legroom and open space to reduce the feeling of confinement during long shifts.

- Basic Ergonomic Controls: Designed with intuitive placement, though they don’t offer the same multi-functionality or adjustability found in Linde controls.

- Sturdy Build: Prioritizes durability, though this sometimes comes at the expense of operator comfort refinements.

Comparison

Linde leads the industry in ergonomics and operator comfort. Its SP Concept—an integrated ergonomic strategy—goes beyond comfort to directly enhance productivity, reduce repetitive stress injuries, and support long-term operator health. With intelligent suspension systems, adaptive controls, and purpose-built comfort technology, Linde forklifts are the clear choice for businesses that prioritize operator well-being and operational efficiency.

3. Maintenance and Total Cost of Ownership

Linde Forklifts

- Hydrostatic drive system: Reduces mechanical wear, leading to longer service intervals and lower maintenance costs, enhancing overall value.

- EVO Models: Linde’s pioneering emission-reducing models align with sustainability goals, making them a future-proof investment.

- Maintenance-Free Systems: Linde’s brake and drive systems require minimal maintenance, reducing downtime and costs.

- Lower Fuel Consumption: The hydrostatic drive system contributes to significant fuel savings over time.

Toyota Forklifts

- Low-Maintenance Systems: Known for low maintenance requirements and high resale value, contributing to a lower total cost of ownership.

Hyster Forklifts

- Durability: Offers durable machines, but maintenance costs can be higher over time, especially for older models.

Comparison

Linde takes a comprehensive approach to operator ergonomics, integrating advanced design and technology to reduce fatigue and increase productivity throughout long shifts.

4. Durability and Longevity

Linde Forklifts

- 20,000-Hour Lifespan: Linde forklifts are rigorously tested to withstand the harshest applications, ensuring a minimum life expectancy of 20,000 hours.

- Reduced Wear and Tear: The hydrostatic drive system minimizes mechanical stress, contributing to longer-lasting performance.

Toyota Forklifts

- 25,000–30,000-Hour Lifespan: Toyota forklifts are known for their exceptional durability, often outlasting competitors.

- High Resale Value: Toyota’s reputation for reliability translates to strong resale value.

Comparison

While Toyota excels in durability and resale value, Linde’s focus on reducing wear and tear through advanced engineering ensures competitive longevity with added efficiency benefits.

Conclusion: Why Linde Forklifts Are Ideal For Your Operations

Linde leads the industry in ergonomics and operator comfort. Its SP Concept—an integrated ergonomic strategy—goes beyond comfort to directly enhance productivity, reduce repetitive stress injuries, and support long-term operator health. With intelligent suspension systems, adaptive controls, and purpose-built comfort technology, Linde forklifts are the clear choice for businesses that prioritize operator well-being and operational efficiency.

Looking for the Best Linde Forklift for Your Fleet?

At Total Warehouse, we specialize in Linde forklifts, sit down, and standup trucks to help you boost productivity and efficiency. Contact us today to explore our Linde forklift options and schedule a demo!

Total Warehouse are proud dealers for Linde, Big Joe, UniCarriers, Landoll. and Dematic. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.