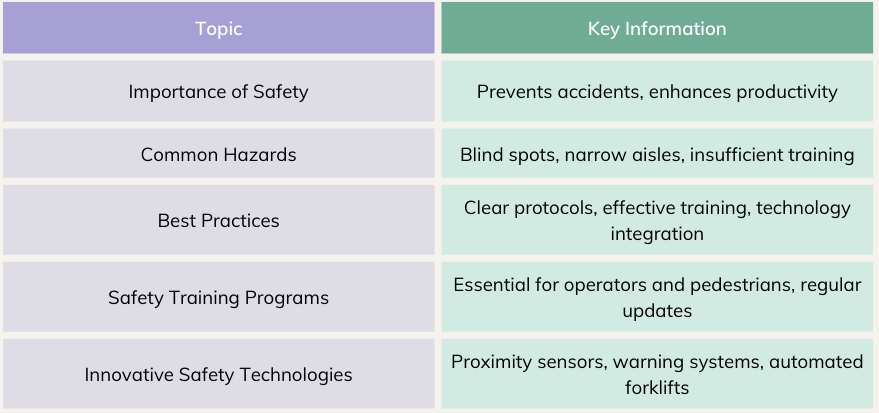

Key Takeaways

Introduction to Forklift and Warehouse Pedestrian Safety

In the bustling environment of a warehouse, ensuring the safety of both forklift operators and pedestrians is paramount. Forklift pedestrian safety is a critical aspect of warehouse operations that, when properly managed, can significantly reduce accidents and improve overall efficiency. Warehouse pedestrian safety encompasses a broad range of practices and protocols designed to protect employees from the various hazards present in a dynamic warehouse setting.

The interplay between forklifts and pedestrians in a warehouse can be fraught with danger if not properly managed. Forklifts, despite their utility, pose significant risks due to their size, speed, and the often crowded and busy nature of warehouse environments. Accidents can lead to severe injuries or even fatalities, highlighting the need for stringent safety measures.

FAQ

Q: Why is forklift pedestrian safety important? A: It prevents accidents and injuries, ensuring a safe and productive work environment.

Q: What are the key components of warehouse pedestrian safety? A: Effective training, clear safety protocols, and the use of advanced safety technologies.

Key Statistics on Warehouse Accidents

Understanding the gravity of forklift-related accidents is crucial. According to recent data, thousands of accidents occur annually involving forklifts, many of which involve pedestrians. These accidents often result from a lack of training, poor visibility, and inadequate safety measures.

Statistics:

- 25% of forklift accidents involve a pedestrian.

- 85 deaths annually in the U.S. are caused by forklift accidents.

- 34,900 serious injuries each year are linked to forklifts.

These statistics underscore the importance of comprehensive safety protocols and regular training to mitigate risks. Warehouses that prioritize safety see fewer accidents, which translates to less downtime and higher productivity.

FAQ

Q: How common are forklift-related accidents? A: Forklift accidents are quite common, with significant injuries and fatalities reported annually.

Q: What factors contribute to these accidents? A: Common factors include inadequate training, poor visibility, and a lack of safety protocols.

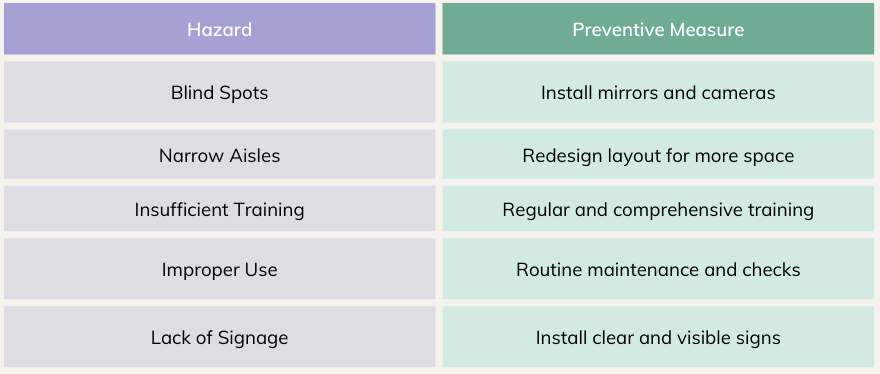

Identifying Common Hazards in the Warehouse

Warehouses are inherently hazardous environments, with a variety of risks that can lead to accidents. Recognizing these hazards is the first step in mitigating them.

Common Hazards:

- Blind Spots: Forklift operators often have limited visibility, especially when carrying large loads.

- Narrow Aisles: Tight spaces increase the risk of collisions.

- Insufficient Training: Both operators and pedestrians need to be aware of safety protocols.

- Improper Use of Equipment: Misuse or faulty equipment can lead to accidents.

- Lack of Signage: Clear signage is essential to guide pedestrian traffic and forklift operations.

Table 1: Common Hazards and Preventive Measures

FAQ

Q: What are the most common hazards in a warehouse? A: Blind spots, narrow aisles, insufficient training, improper use of equipment, and lack of signage.

Q: How can these hazards be mitigated? A: Through effective layout design, regular training, routine maintenance, and clear signage.

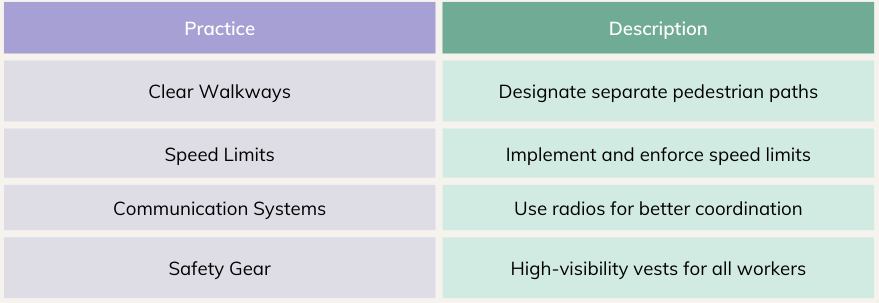

Implementing Best Practices for Safety

Best practices for forklift pedestrian safety involve a combination of training, technology, and clear protocols. Implementing these practices can create a safer and more efficient warehouse environment.

Safety Protocols:

- Clear Walkways: Designate and mark pedestrian walkways to separate them from forklift traffic.

- Speed Limits: Enforce speed limits for forklifts to reduce the risk of collisions.

- Communication Systems: Use two-way radios or other communication tools to enhance coordination between operators and pedestrians.

- Safety Gear: Ensure all employees wear appropriate safety gear, such as high-visibility vests.

Table 2: Best Practices for Forklift Pedestrian Safety

FAQ

Q: What are some best practices for forklift pedestrian safety? A: Best practices include clear walkways, speed limits, effective communication systems, and mandatory safety gear.

Q: How can these practices be enforced? A: Through regular training, strict enforcement of rules, and the use of technology to monitor compliance.

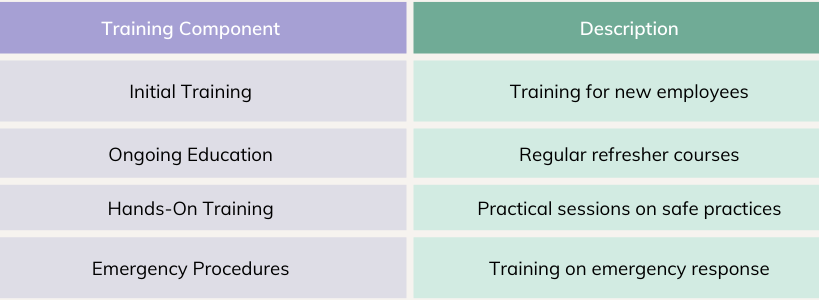

The Importance of Forklift Pedestrian Safety Training

Safety training is the cornerstone of an effective forklift and warehouse pedestrian safety strategy. Comprehensive training programs ensure that both operators and pedestrians understand the risks and know how to mitigate them.

Components of Effective Training:

- Initial Training: All new employees should receive training before starting work in the warehouse.

- Ongoing Education: Regular refresher courses to keep safety protocols top-of-mind.

- Hands-On Training: Practical sessions where employees can practice safe operation and pedestrian navigation.

- Emergency Procedures: Training on what to do in case of an accident or emergency.

Table 3: Components of Effective Safety Training

Investing in training programs not only enhances safety but also boosts employee confidence and operational efficiency.

FAQ

Q: Why is safety training important? A: It ensures that employees are aware of risks and know how to mitigate them, reducing accidents and improving safety.

Q: What should safety training programs include? A: Initial training, ongoing education, hands-on practice, and emergency procedures.

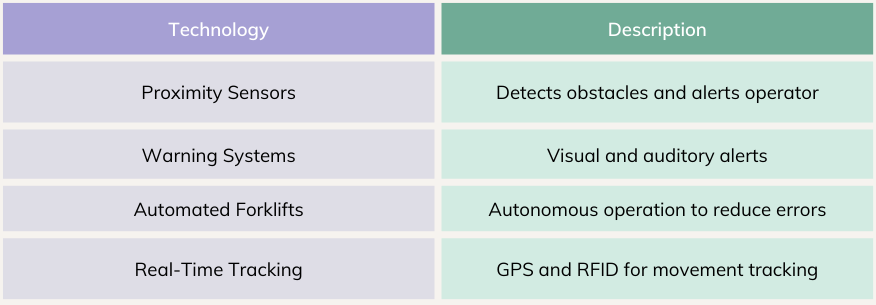

6. Innovative Safety Technologies

The integration of cutting-edge technologies can significantly enhance forklift and warehouse pedestrian safety. These technologies not only help in preventing accidents but also streamline warehouse operations, making them more efficient.

Advanced Safety Technologies:

- Proximity Sensors: These sensors detect obstacles and pedestrians in the path of a forklift, alerting the operator to potential hazards.

- Warning Systems: Visual and auditory alarms that activate when a pedestrian is nearby, ensuring both the operator and pedestrian are aware of each other’s presence.

- Automated Forklifts: Autonomous forklifts reduce human error, as they are equipped with advanced navigation systems to avoid collisions.

- Real-Time Tracking: GPS and RFID systems track the movement of forklifts and pedestrians, helping in route optimization and collision prevention.

Table 4: Innovative Safety Technologies

FAQ

Q: What are proximity sensors used for in forklifts? A: They detect obstacles and alert the operator to prevent collisions.

Q: How do automated forklifts enhance safety? A: They minimize human error through advanced navigation systems, reducing the risk of accidents.

Designing a Safe Warehouse Layout

A well-designed warehouse layout is crucial for minimizing risks and ensuring the smooth flow of both forklift traffic and pedestrian movement. Proper layout planning can greatly enhance safety and efficiency.

Layout Design Tips:

- Separate Paths: Clearly defined paths for forklifts and pedestrians to avoid intersections.

- Adequate Lighting: Proper illumination to eliminate blind spots and improve visibility.

- Clear Signage: Use of signs to indicate pedestrian crossings, forklift routes, and restricted areas.

- Spacious Aisles: Wider aisles to accommodate safe forklift operation and pedestrian movement.

- Safety Barriers: Install barriers to protect pedestrian walkways from forklift traffic.

Bullet Points: Warehouse Layout Best Practices

- Designate separate paths for forklifts and pedestrians.

- Ensure proper lighting throughout the warehouse.

- Use clear and visible signage.

- Maintain spacious aisles for easy movement.

- Install safety barriers where necessary.

FAQ

Q: Why is a well-designed warehouse layout important? A: It reduces the risk of accidents by clearly separating forklift and pedestrian paths and improving visibility.

Q: What are some key elements of a safe warehouse layout? A: Separate paths, adequate lighting, clear signage, spacious aisles, and safety barriers.

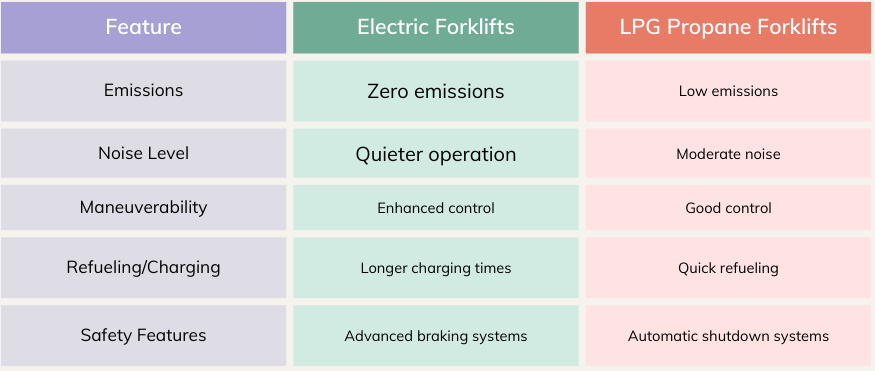

Benefits of Electric and LPG Propane Forklifts

Choosing the right type of forklift can significantly impact warehouse safety. Electric and LPG propane forklifts offer several advantages over traditional internal combustion forklifts, particularly in terms of safety and efficiency.

Benefits:

- Electric Forklifts:

- Lower Emissions: Produce no harmful emissions, making them safer for indoor use.

- Quieter Operation: Reduced noise levels improve communication and awareness.

- Enhanced Control: Advanced braking and control systems for better maneuverability.

- LPG Propane Forklifts:

- Consistent Power: Provide consistent performance in various conditions.

- Refueling Efficiency: Quick refueling compared to battery charging.

- Safety Features: Equipped with safety features like automatic shutdown systems.

Table 5: Comparison of Electric and LPG Propane Forklifts

FAQ

Q: What are the safety benefits of electric forklifts? A: They produce no emissions and operate quietly, reducing indoor pollution and improving communication.

Q: How do LPG propane forklifts ensure safety? A: They offer consistent power and are equipped with safety features like automatic shutdown systems.

Fleet Management for Enhanced Safety

Effective fleet management is essential for maintaining a safe and efficient warehouse environment. By leveraging fleet management services, businesses can ensure regular maintenance, compliance with safety standards, and optimal performance of their forklifts.

Fleet Management Benefits:

- Regular Maintenance: Ensures forklifts are in good working condition, reducing the risk of mechanical failures.

- Safety Compliance: Keeps forklifts compliant with safety regulations and standards.

- Performance Monitoring: Tracks the performance of each forklift, identifying issues before they lead to accidents.

- Cost Efficiency: Reduces downtime and maintenance costs by proactively managing the fleet.

Bullet Points: Key Aspects of Fleet Management

- Schedule regular maintenance checks.

- Ensure compliance with safety standards.

- Monitor forklift performance continuously.

- Implement cost-efficient management strategies.

FAQ

Q: Why is fleet management important for warehouse safety? A: It ensures that forklifts are well-maintained, compliant with safety standards, and operating efficiently, thereby reducing the risk of accidents.

Q: What are the key benefits of effective fleet management? A: Regular maintenance, safety compliance, performance monitoring, and cost efficiency.