Traditionally, your inventory is to be held on pallets, which are moved from the loading dock to their rack position, and then back to the loading dock to be shipped out. If you store on pallets, you will need a pallet rack system, or if you don’t store your inventory on pallets, you will need to use a shelving system.

Storing stock on pallets is highly recommended unless not possible. Though it should be mentioned that most warehouses will have a mix of racking and shelving in their operation. If you don’t work with pallets then your warehouse storage project will be very easy, but very limiting: You should have a boltless shelving system custom designed and installed for your exact facility and inventory specifications.

Are you looking for onsite rack engineering? Check out our service today!

Are you storing inventory on pallets?

Storing material with pallets and rack is a little trickier, but much more rewarding. Pallets allow you to pack inventory more densely and securely than lose inventory on shelves. Also, Pallets can be easily handled and moved by forklifts and stackers to get your inventory where it needs to go more efficiently than having a human move stock individually. Your company will succeed if you’re able to move your commodity on a massive level, and that means on pallets.

Finally, pallet racking gives you more control over the performance of your warehouse. The term “pallet positions” is a quantifiable metric for how much inventory your warehouse can hold. When your rack system is installed, you will be given a pallet position number that you can use to determine your warehouse’s flow of inventory.

Example:

If you know your system holds a max of 350 pallet positions, and you know you’re shipping out 175 Pallets a day, you then know you’re experiencing a 50% daily turnover of inventory. That way your stock purchasing and facility performance can be tracked with real hard data.

Long story short: Always store on pallets unless not possible.

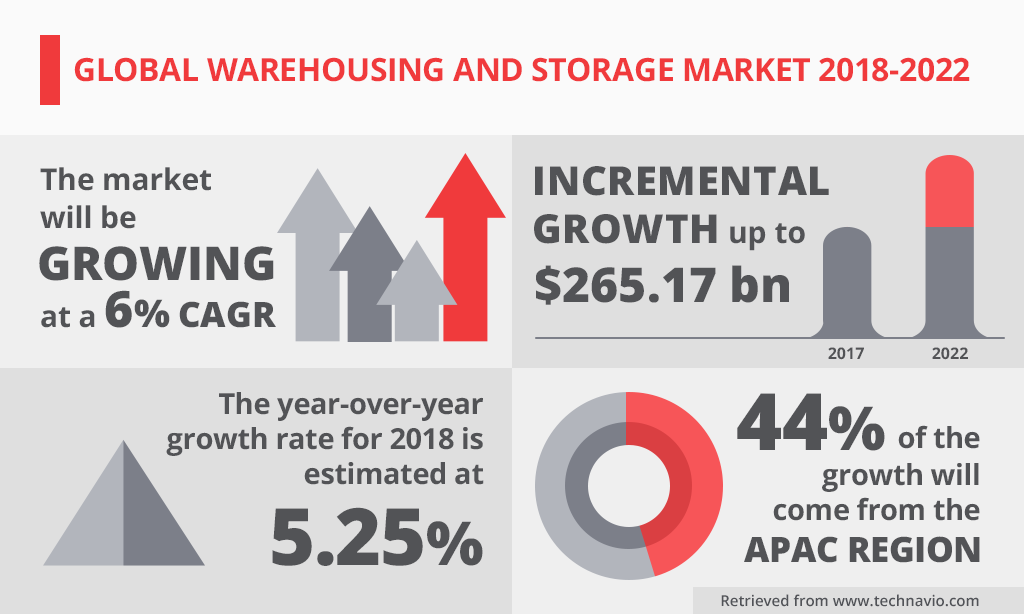

According to Technavio, the global warehousing and storage market is expected to have 5.25% YoY growth from 2018 to 2022.” This is why it’s more important than ever before to optimize your warehouse.

How many different types of Inventory are you going to store?

If your company handles only one type of inventory or SKU, you will fill your warehouse with an entirely different type of racking system than you would if you have a wide range of inventory types to be handled.

Minimal variety in inventory means you can pack identical pallets -one after the other- into push back, drive-in, or skate wheel systems that offer awesome storage density due to their lack of need for aisles.

Conversely, if your company handles a wide ariety of material, you’ll need the ability to access that material and thus will need to store your pallets in conventional rack systems with aisles. But, even conventional aisle-based rack systems can be optimized to increase storage density and pallet positions. More about that later.

Looking to optimize your warehouse? Contact us today!