Warehouse Safety and Transverse & Longitudinal Flue Spaces

At Total Warehouse, our team of engineers design warehouse storage systems that go beyond capacity—they’re built for safety, fire code compliance, and operational efficiency. One of the most critical yet often overlooked components in pallet rack design is flue space.

Defined by the National Fire Protection Association (NFPA), flue space refers to the open vertical areas within a racking system that allow heat and smoke to rise and activate overhead sprinkler systems during a fire. Fire safety is a critical priority in material handling operations and properly maintaining flue space between warehouse racks helps prevent fire spread and supports safer emergency response.

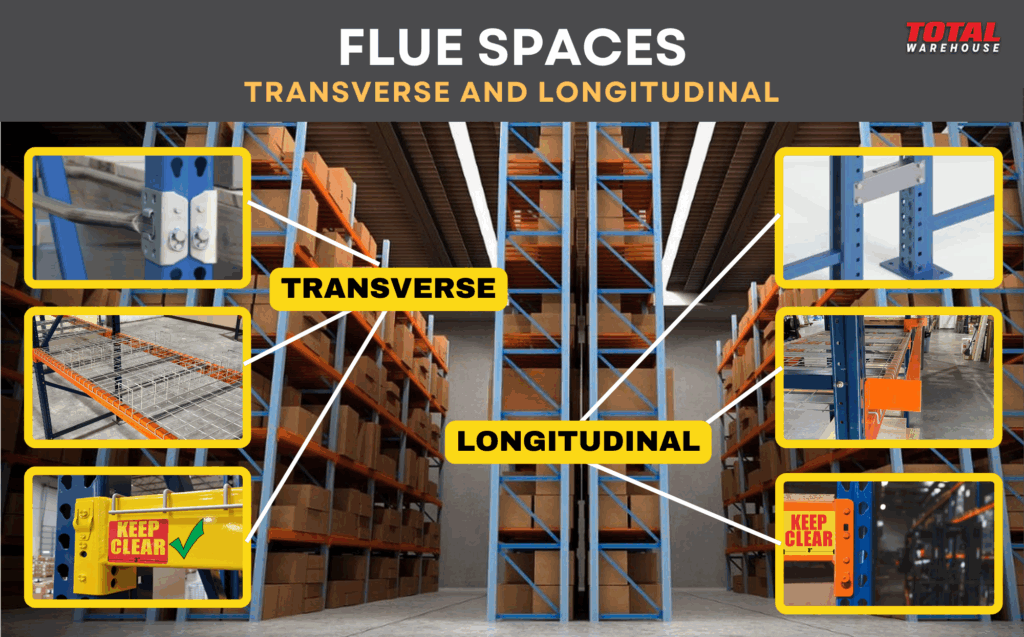

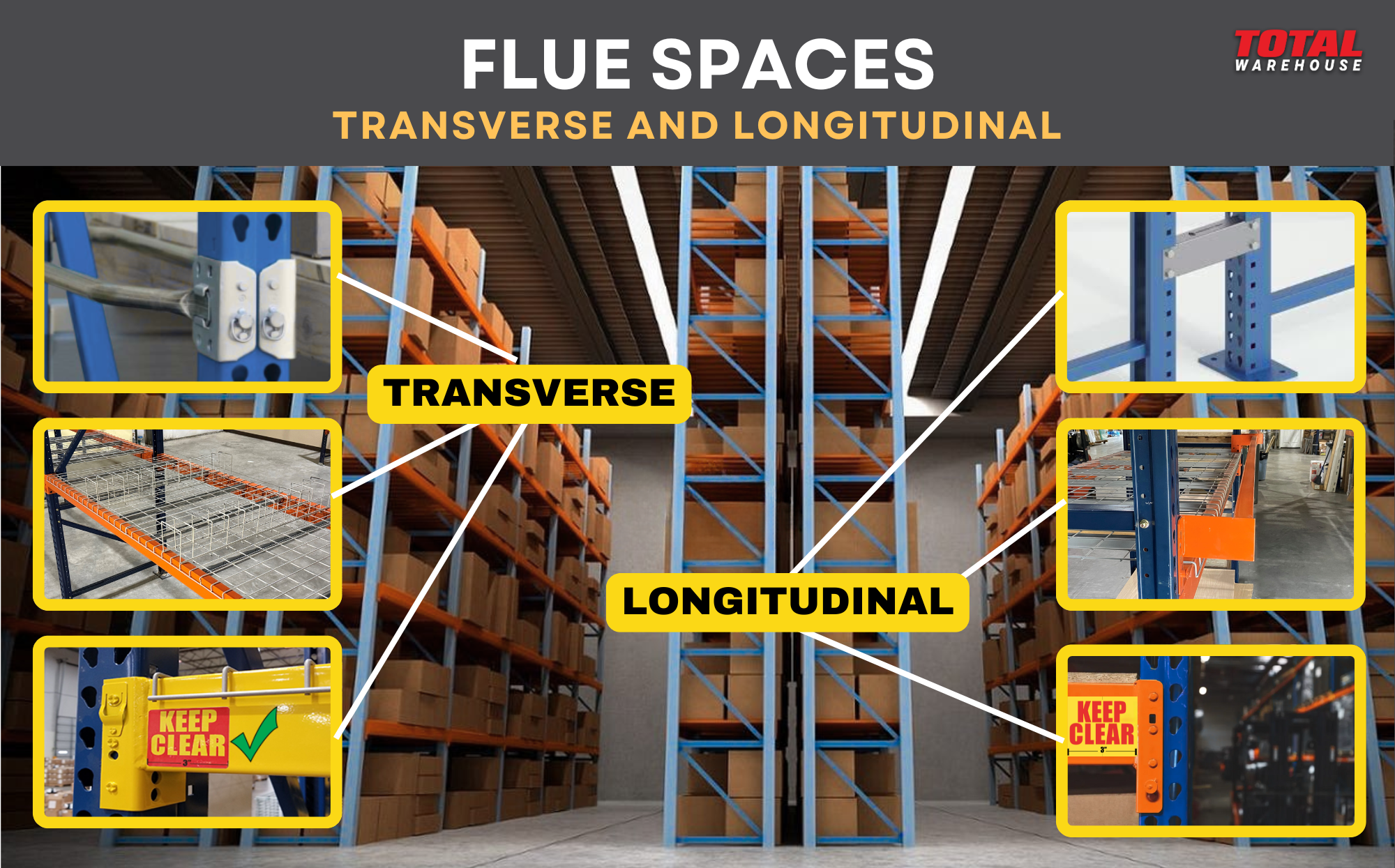

There are 2 types of flue space TW engineers ccount for: transverse and longitudinal. Learn how to protect your warehouse, employees, and inventory.

What is Transverse Flue Space?

Transverse flue space is the gap between pallets stored side-by-side on the same beam level. This spacing runs parallel to the direction of pallet loading.

- NFPA Requirement: 6 inches minimum between loads

- Why It Matters: Ensures proper sprinkler penetration and fire containment

- Common Misconception: A 92” beam with two 40” pallets leaves only 4” total flue space—not compliant

- Compliant Layout: A 96” beam with two 40” pallets provides 6” between loads and 5” on either side

Solutions We Recommend:

- Flue Keepers: Prevent pallets from encroaching into the flue space

- Snap-on Wire Dividers: Serve as visual guides for forklift operators

- “Keep Clear” Labels: Help communicate spacing requirements clearl

What is Longitudinal Flue Space?

Longitudinal flue space is the gap between back-to-back rows of pallet racks, running perpendicular to the loading direction.

- NFPA Requirement: 6 inches minimum (can vary by local fire code or product combustibility)

- Typical Design Scenario:

- 42” deep uprights

- 48” deep pallets with 3” overhang on front and rear

- Requires 12” total flue space (3” + 3” overhang + 6” clear flue)

Why It Matters:

- Allows heat and smoke to rise between racking rows

- Enhances the reach and effectiveness of sprinkler systems

- Prevents fire spread across entire rack bays

Solutions We Recommend:

- Row Spacers: Maintain consistent spacing during installation

- Pallet Load Stops: Physically limit how deep pallets can be placed

- Custom Layouts: Based on local code, commodity class, and equipment specs

Why is Flue Space Compliance Critical?

Neglecting proper flue spacing puts your people, inventory, and facility at risk. Obstructed or poorly designed flue spaces can prevent sprinkler systems from activating properly, allowing fires to spread across bays and rows unchecked. According to the NFPA, many warehouse fires result in significant damage due to non-compliant or blocked flue space.

Our warehouse storage space engineers ensure that every pallet position and rack row is engineered to fire code standards—no matter your load type, pallet size, or warehouse layout.

How To Maintain Clear Flue Space In Your Racking System

To stay compliant with safety regulations, it’s essential to keep your 3” transverse and 6” longitudinal flue spaces free of any obstructions. Pallets pushed too far back during loading can quickly violate this spacing—posing a serious fire safety risk. Here are effective solutions to prevent pallet push-through:

- Rack Straps – Installed at the back of each bay to stop pallets from entering the flue space.

- Pallet Stop Beams – Mounted 6–12” above the rear beam level to act as a physical barrier against push-through.

- Wire Rack Backing – Primarily used for safety, this can also prevent pallets from breaching flue space boundaries.

Partner With Total Warehouse for Safer Racking Systems

From concept to installation, Total Warehouse provides full-service support to help you:

- Design rack systems with code-compliant transverse and longitudinal flue space

- Install visual markers, row spacers, pallet stops, and more

- Pass fire inspections and reduce liability risks

- Maintain safety and functionality as your layout evolves

Learn More: TW Engineers

Raising the Bar for Reliability — The Total Warehouse Standard

Ready For Expert Pallet Rack Design and Installation?

Our expert engineers are here to help your space stay smart—and safe with back-to-back rack design and storage solution configuration projects. Ready to evaluate or redesign your flue space layout? Contact us today for a consultation. We partner directly with your team to ensure that your storage system is designed to the proper and safe design parameters to ensure operational efficiency, safety, and compliance. Contact us today to get started on your next pallet racking or warehousing design project.