Key Features

Maximize Your Storage Density

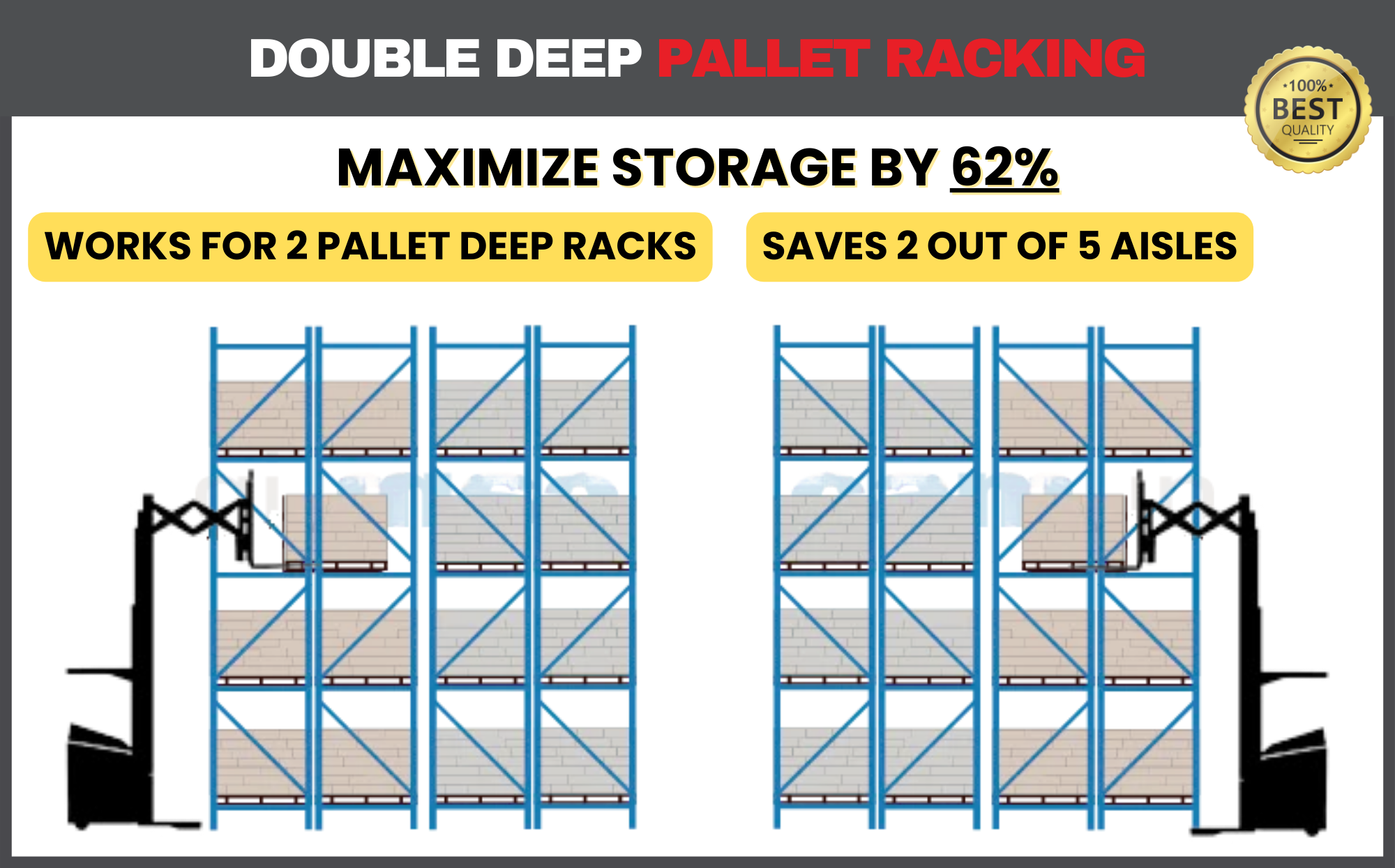

Double deep pallet racking maximizes the use of vertical and horizontal space by allowing pallets to be stored two rows deep. This configuration effectively doubles the storage capacity compared to traditional single-deep systems, making it ideal for warehouses with limited floor space.

Double deep pallet racking can increase storage density up to 40% with good selectivity.

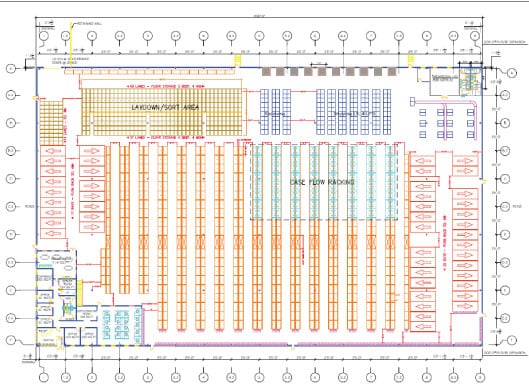

Maximize Your Floor Space

By reducing the number of aisles needed for access, double deep racking optimizes the layout of your warehouse. This creates more room for storage and ensures better utilization of available space, increasing floor space by 60–65%.

Cost-Effective Racking Configuration

Double deep pallet racks are one of the most cost-effective high density storage solutions. They provide an affordable solution for increasing storage capacity without expanding the physical size of your warehouse. This minimizes the need for costly building expansions or additional facilities.

Access Stock Quickly and Easily

Although double deep systems require specialized forklifts with telescopic forks, they still allow for quick and efficient access to pallets. With proper organization and inventory management, products can be retrieved with minimal effort, maintaining workflow efficiency.

Explore our Double Deep Reach Trucks

Safeguard Your Storage

Double deep pallet racking systems can help make the storage process safer. Double deep racking is designed to securely hold heavy loads, reducing the risk of items falling or becoming damaged. The system promotes a safer working environment by ensuring stability and compliance with U.S. warehouse safety regulations.

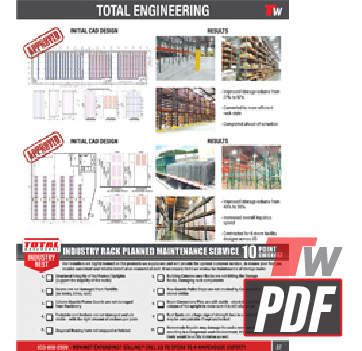

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

Double Deep Value

Provides 30-40% more pallet locations compared to single entry shelving, while ensuring 50% product accessibility at all times. Its compact design optimizes warehouse space, striking a favorable balance between storage capacity and accessibility.

- Best Floor Space Usage with Strong Aisle/Shelving Ratio

- Keep Product Lines Together by Storing 2 Pallets Deep

- Increase storage density by around 30-40%

- Cost-effective Racking Configuration

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.