Connect:Desk in Detail

Revolutionizing Your Forklift Fleet Management

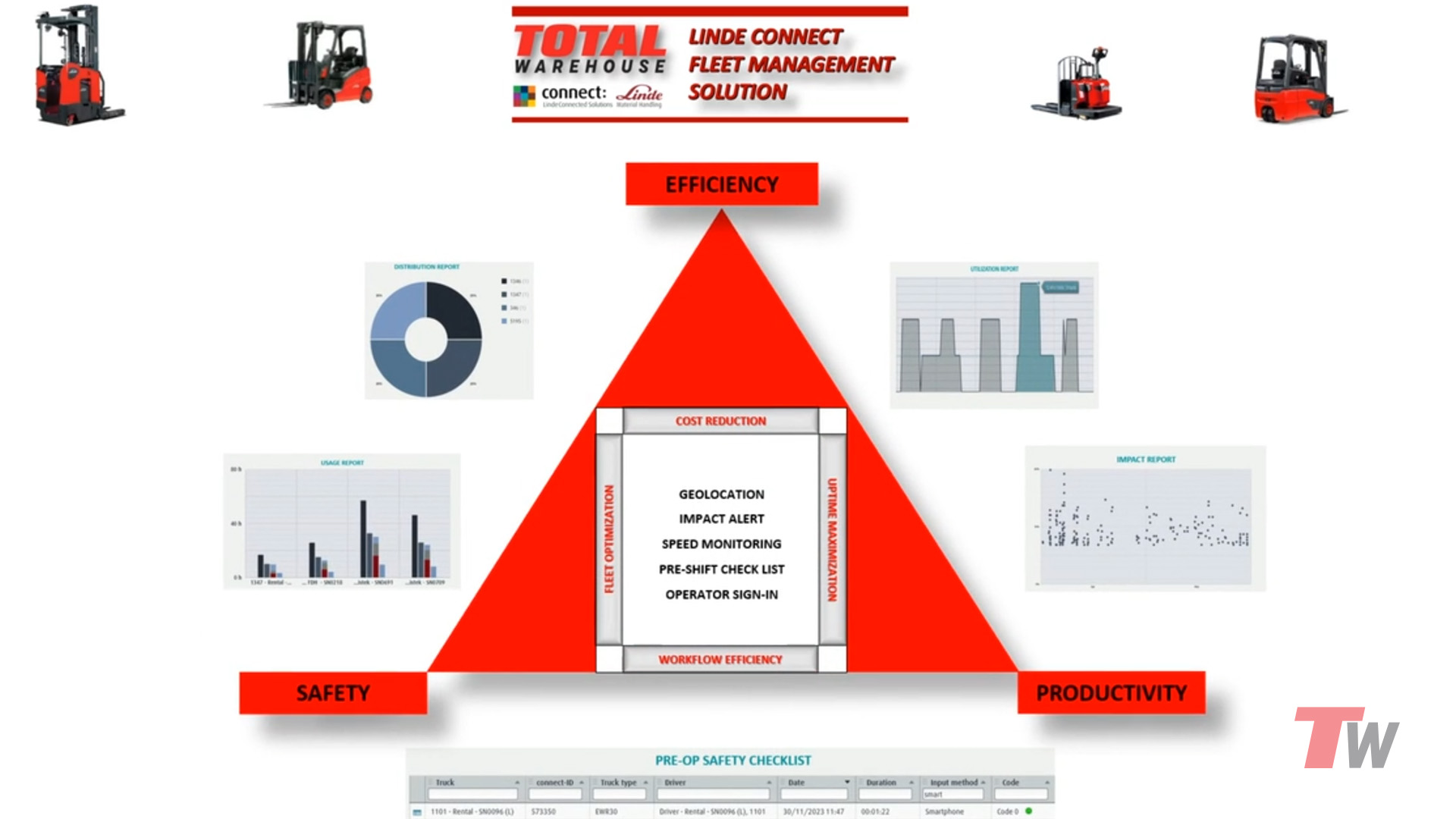

Digitization is transforming the world of intralogistics, with modern devices constantly gathering data for optimizing complex warehouse and transport operations.

The connect:desk fleet management system provides clear access to all your fleet data – managing forklift truck and driver data for effortless compilation of reports. Whether it’s in production or the warehouse, connect networks your forklifts and keeps you informed of your entire fleet’s current status.

Fleet Management Dashboard

Dashboard: Monitor the entire fleet on our communication hub with customizable widgets such as the calendar and forklift truck notifications, with all messages forwarded directly via email.

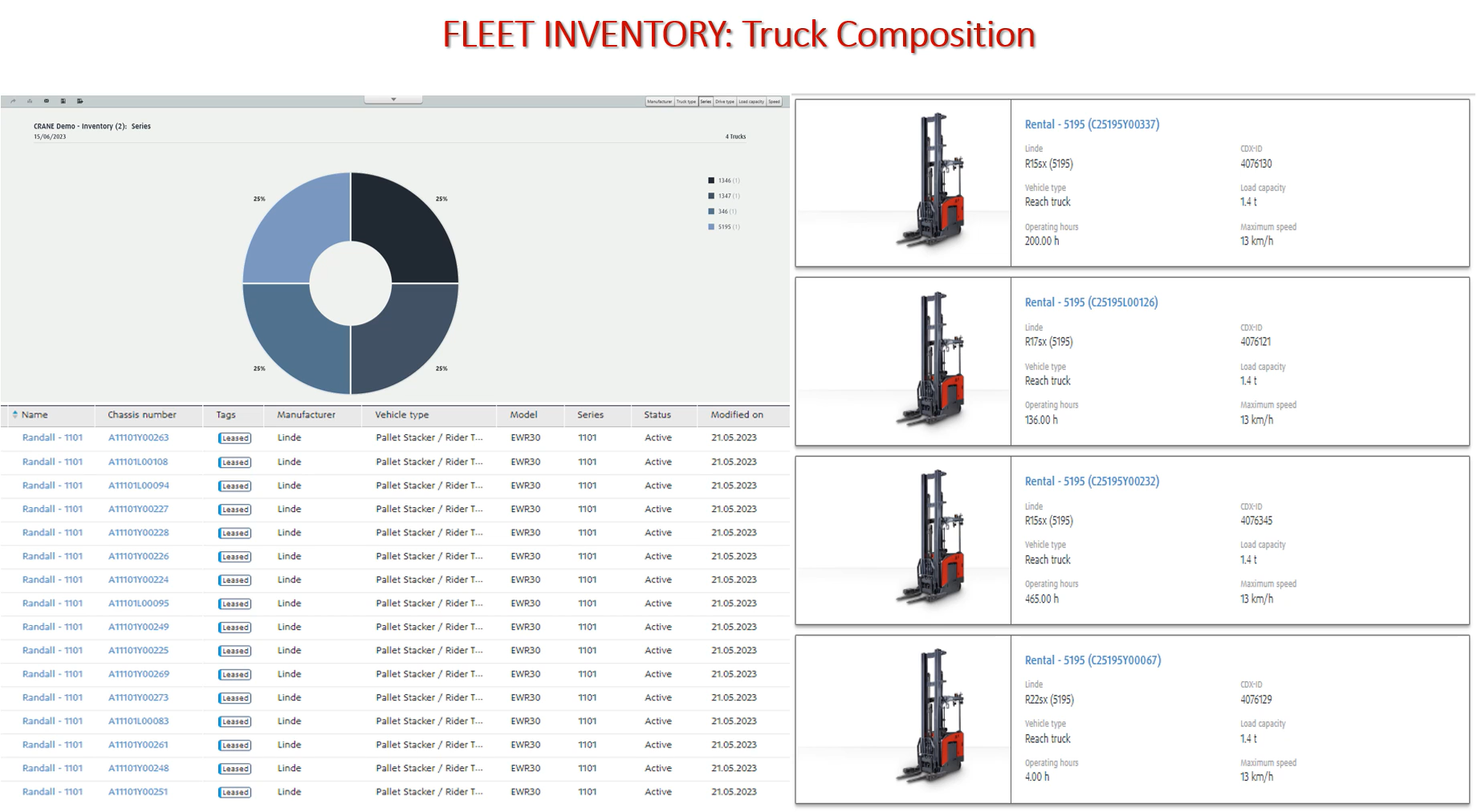

Organization: Make modifications to the driver, job location, assigned forklift trucks and other information. The structured list display offers an overview of the organizational structure, simplifying the assignment and management of access and usage rights.

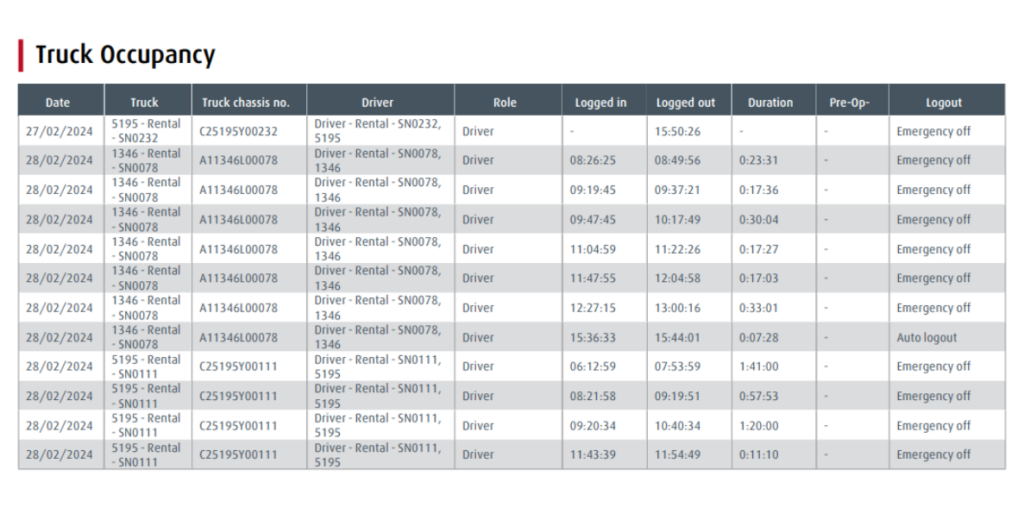

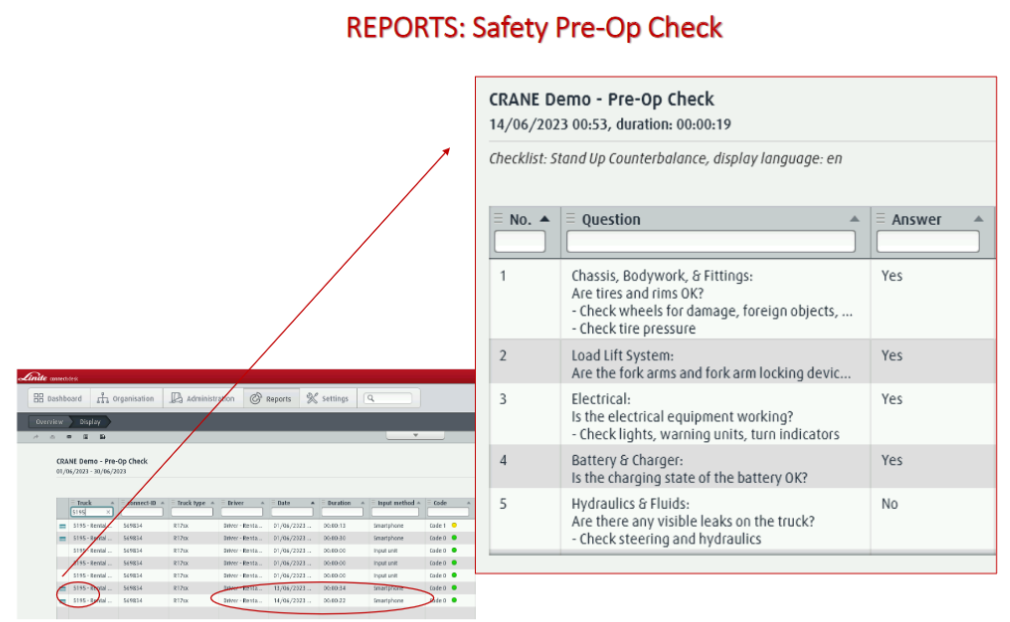

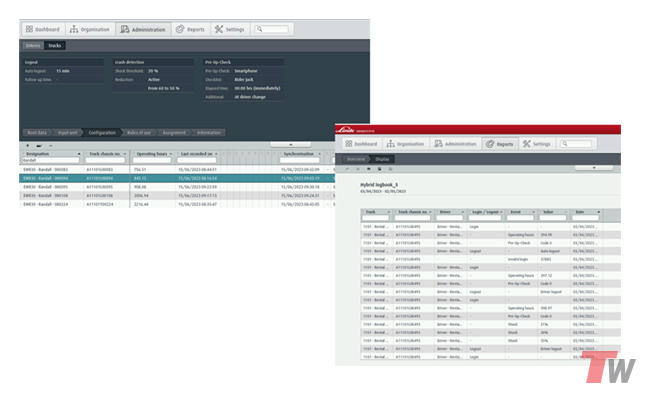

Administration & Login Reports

Administration: Enable flexible viewing, maintenance, and expansion of large amounts of data with tables, detailed views, and various input elements. Ex. Drivers’ licenses, training, and health checks can be managed with ease.

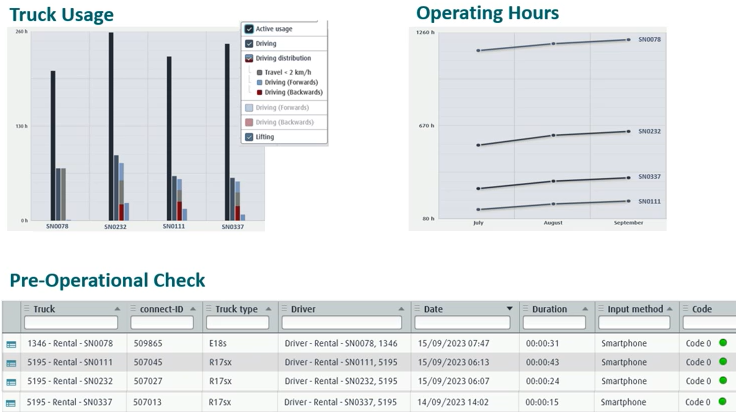

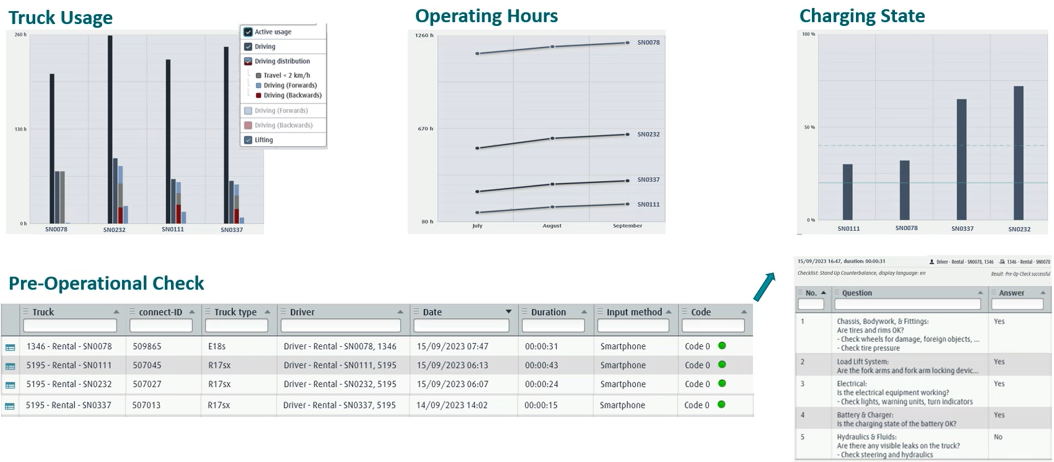

Login Reports: Interactive diagrams to track unusual charging levels and logouts, grouped by driver and forklift truck. The log book offers a summary of recorded events, including pre-op checks and drivers’ responses for selected units.

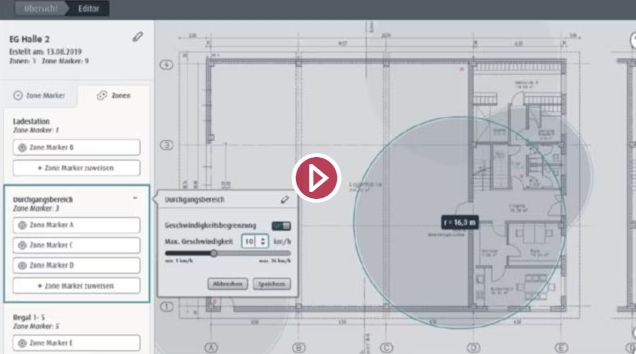

Linde Safety Zones

Linde Safety Guard: Configure restricted zones for trucks, enforcing either a prohibition or reduced speed (such as at crossings or narrow areas), and monitor their travel to determine the optimal paths within your warehouse.

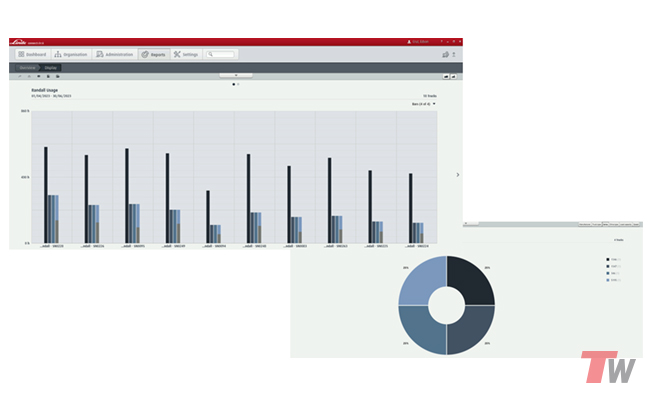

Forklift Usage & Coordination Reports

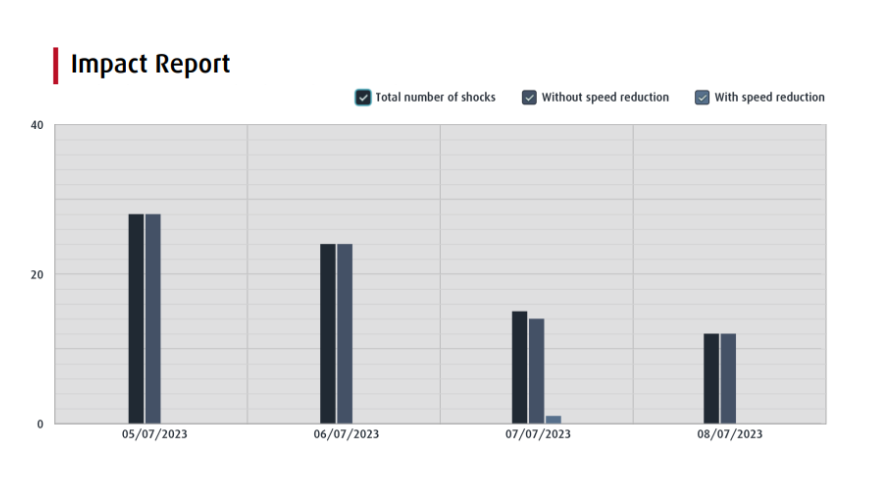

Usage Report: Receive insights into the performance and operation of your forklift trucks with an overview of usage and capacity utilization. The interactive diagram displays driver activity duration, reasons for usage, shock values, battery charge progression, and zone passages distribution.

Coordination Reports: Receive data on drivers, forklift truck usage, and capacity utilization. The forklift truck distribution categorizes the entire fleet based on manufacturer, type, and other criteria, while the fleet list details important characteristics, and driver training status is available under driver training.

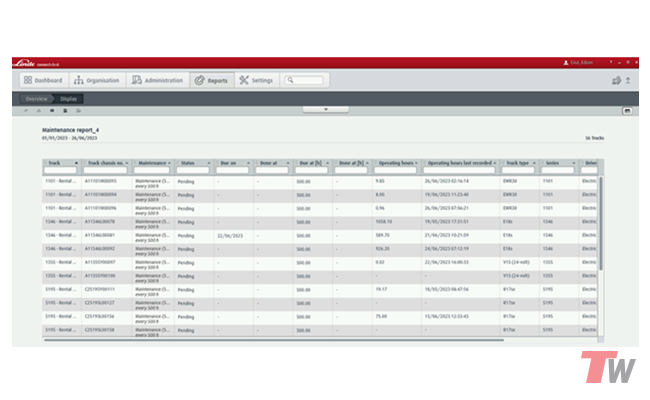

Service Reports

Service Area: The service area lists the service and maintenance dates for all fleet forklift trucks. Fleet managers can strategically bundle maintenance dates in a targeted manner to achieve reduced costs.

Advantages of Forklift Tracking

Forklift tracking provides numerous benefits, which can be categorized into asset and operational domains.

Forklift tracking enhances asset management by consolidating records, maximizing uptime, optimizing charging scenarios, and identifying avoidable maintenance. It also aids in planning preventative maintenance and managing spare parts inventory.

For operational management, forklift tracking automates decisions and communication, forecasts cost centers, and promotes safety through data-driven insights. Additionally, it helps manage rental contracts, perform quantitative analytics, and determine the total cost of ownership.

Learn More: Benefits of Forklift Asset Management Systems

CONNECT:DESK PORTAL

Real-Time Information & Real-World Value

Connect:Desk is a convenient web portal that allows authorized users to seamlessly access fleet and operator data from any internet-connected device.

- Early Detection and Resolution of Issues

- Real-Time Track and Monitor Trends

- Fleet Utilization Surveillance

- Evaluate Operator Performance

Uniqueness Unveiled

Linde Fleet Management

As your business requirements shift, Linde-Connect evolves and provides a scalable, versatile, and customizable solution. Scalable Solution with Actionable Data

- Readily Available Data on Entire Fleet

- Customized Report and Automation

- Actionable Insights

- Compatible With Many Industrial Vehicles

- Cellular and Wi-Fi Data Communication

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.