Key Features

Double the Depth, Double the Capacity

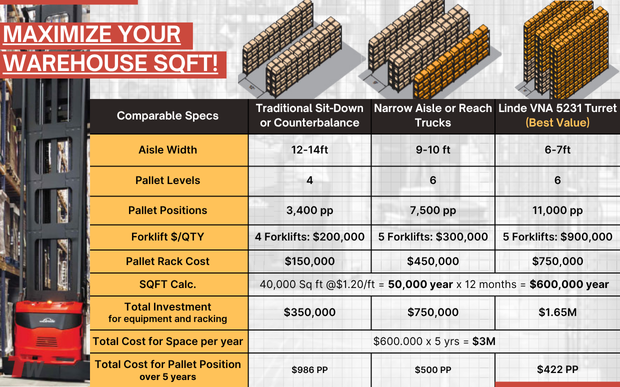

Maximize warehouse efficiency with high-density storage that boosts selectivity, reduces forklift travel, and optimizes space for faster, safer operations.

- Store 2–6 pallets deep without expanding your footprint

- Maintain access to multiple SKUs while maximizing storage density

- Boost safety by reducing congestion and forklift travel distance with fewer aisles

- Lower labor costs and equipment wear through streamlined movement

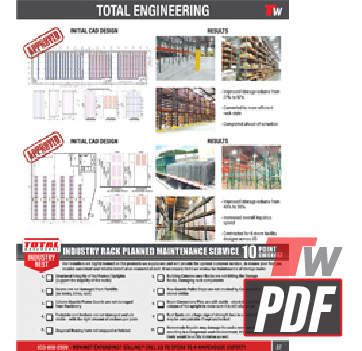

TW Engineered Solutions

Our experts design personalized, expert solutions to optimize your storage space.

- We Analyze Your Space & Load Requirements

- We Perform Comprehensive Seismic Calculations

- We Provide Detailed CAD Designs for Tailored Rack Systems

- Receive a Comprehensive Site Analysis

- We Match BEST EQT Utilization for Maximizing Space

Learn More: TW Engineers

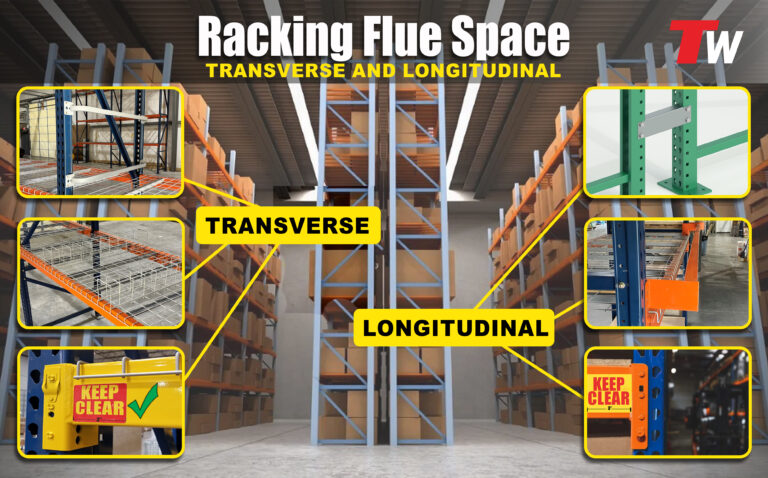

Flue Space Optimization

Proper transverse and longitudinal flue spacing is essential for fire safety and sprinkler performance. Our layouts ensure code-compliant spacing, using tools like indicator bars and labels to maintain clearances and support NFPA requirements.

- Transverse Spacing: Between pallets side-to-side

- Longitudinal spacing: Between rack rows front-to-back

- Supports NFPA and local fire codes

- Enhances sprinkler coverage and emergency response

- Reduces risk of blocked water distribution

Learn More: Pallet Rack Flue Space

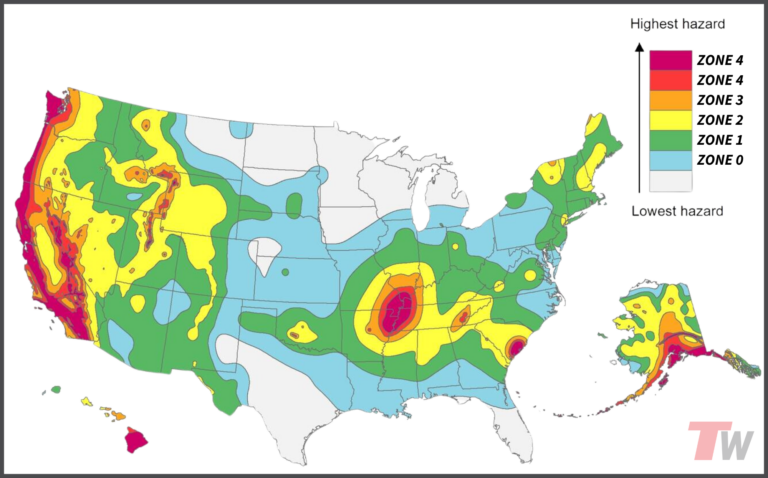

Seismic Engineering & Structural/Building Permits

Seismic zones dictate the earthquake resistance required for safe, compliant racking. We provide structural and seismic calculations to prevent collapse, protect inventory and staff, and minimize downtime in your area.

TW Engineering & Design Experts Provide:

- Seismic-compliant racking with structural analysis

- Code-compliant, permit-ready documentation

- Full support with permit submittals and regulatory compliance

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

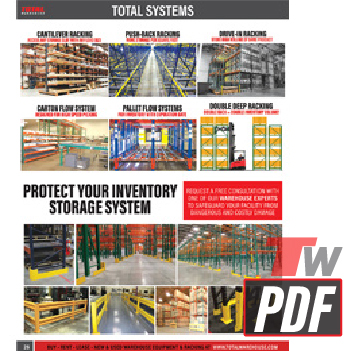

High Density

Storage Solution

Enables higher-density storage by storing multiple pallets stacked deep on each level, loaded from the front. Ideal for high-productivity operations with frequent stock turnover.

- Selective Storage & High-Density Storage

- Efficiently Store & Manage Inventory

- Enables 3x More Storage Space

- Decreases Costs with Space Optimization

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.