A January 2021 report by e-commerce media and research organization Digital Commerce 360 stated that US eCommerce grew an incredible 44% in 2020 from 2019’s 15.8%.

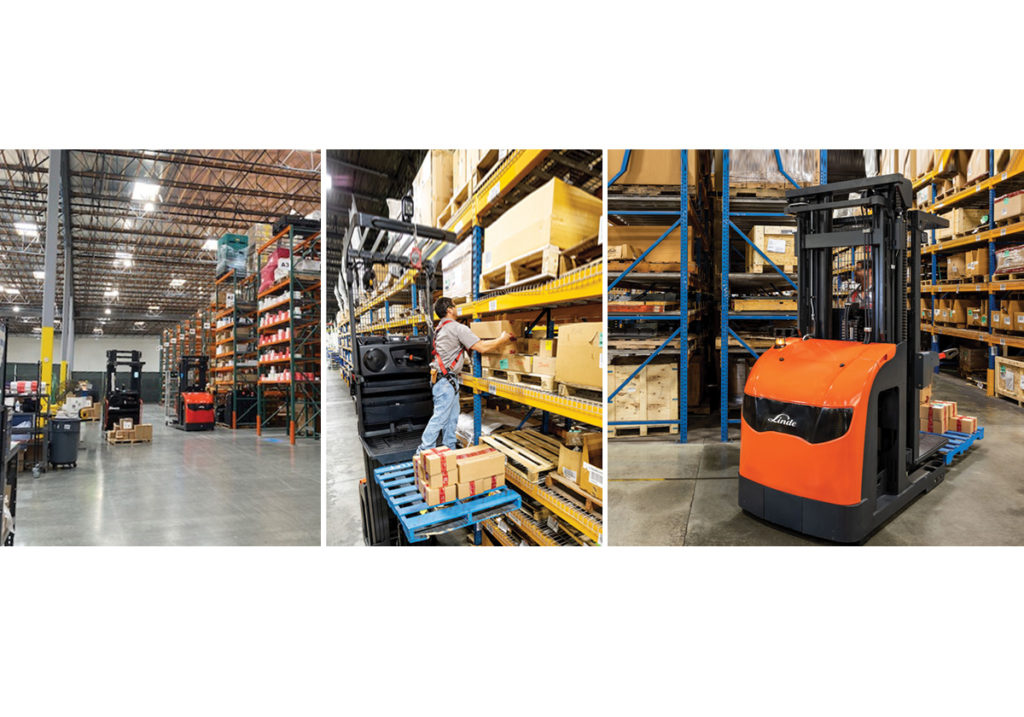

With the rise of consumers buying online, the need increased for warehouse companies to quickly adopt pick and pack operations to keep up with e-commerce order fulfillment. This means that warehouses also need to have the right equipment for pick and pack processes.

This article discusses order pickers and how they differ from forklifts. It also gives an overview of the three basic types of order pickers for sale.

The Role of Order Pickers

Order pickers work best in warehouses that operate for retail and archival storage. They are also an important part of pick and pack operations. When it comes to specific warehouse processes, they are a good fit for:

- Batch Picking: This is done when the inventory needs to be pulled for multiple orders at a time.

- Spacing: It’s the process of placing most goods in different aisles for less congestion and optimizing movement in the warehouse.

- Slotting: This is the method of organizing inventory to make order picking fast and efficient.

Most people unfamiliar with warehouse operations consider order pickers and forklifts to be the same thing. The biggest difference between the two is where the operator is staying.

- In a forklift, like reach trucks, the operator is sitting on the driver’s seat. From there the operator uses hand controls to move the lifting mechanisms. It’s designed for operations that need higher lift capability.

- In an order picker, the operator goes up with the load. They move pallets or smaller loads on and off the equipment manually. The order picker is designed to have an operator on the same level as the inventory to pick a specific order.

Common Order Pickers

While there are other specialized kinds of order pickers available, these are the three popular types:

Standard Order Picker

This is the most common order picking equipment. It’s found in most warehouses that require product picking.

It’s the default order picker of warehouses. If you are introducing pick and pack operations, this is a good piece of equipment to start with.

Its lift heights vary depending on the manufacturer, but most are capable of reaching 300 inches to retrieve items from medium to high locations.

The operator’s compartment provides some level of comfort and can handle full pallet loads. This means it can carry a lot of products simultaneously.

Most standard order pickers can be paired with wire guidance systems and rail-guided layouts. This makes the equipment faster and safer and with better throughput.

High-Level Order Picker

This order picker is capable of reaching products in up to 550 inches. Its reach supports warehouse racking systems that maximize vertical storage space.

If you are looking to optimize your warehouse by adding storage space at higher locations, then this equipment is the right choice.

High-level order pickers are fast and powerful with the capability of running 16 hours on a single charge of its 48-volt battery.

It’s one of the best in the market. When equipped with the latest technology like the warehouse navigation system, its picking speed can increase by 25% and it can drive or lift itself in the most efficient way possible.

Low-Level Order Picker

If your warehouse layout is designed to store bulk products higher up the racks and picked products are stored lower down, this order picker is the right fit.

Low-level order pickers are designed to pick products from floor level up to 180 inches. The machine is perfect for moving around the warehouse fast and picking up in seconds.

It is fast and maneuverable. Operators can also get on and off quickly with minimal risk.

This unit’s ground clearance also means that any uneven floor, debris, or ramp will not hinder its quick movements. Low-level order pickers are often considered one of the best-kept secrets in the industry.

Cost and Brand

The average cost of a standard order picker may range from $4,000 to $10,000, depending on the fuel, the type, and any additional accessories.

Some of the best brands offering order pickers for sale are Yale, Big Joe, Linde, Toyota Forklifts, and more.

Choosing the right order picker is a smart move in optimizing your warehouse. By understanding how popular order pickers are designed and how they work, you will find the best equipment that will make your operations cost-efficient and convenient.