Explore the Power of Lithium Ion Batteries and Chargers

Exploring the advantages of Lithium-Ion Batteries and Chargers for your forklift fleet management.

Li-Ion Energy Solutions

Embracing innovation is crucial for businesses aiming to stay at the forefront, and a growing number of forward-thinking enterprises are making the switch to electric forklifts. The recognition of their myriad benefits in terms of sustainability and efficiency is driving this shift.

Among electric forklifts, a standout game-changer is making waves in the industry: forklifts equipped with cutting-edge lithium-ion batteries and chargers.

Linde’s advanced energy solutions entail state-of-the-art technology for reducing energy costs and maximizing performance. Linde Li-ION Chargers and lithium ion batteries are ideal for every application and provide a multi-level safety concept, emission and maintenance-free technology, convenient charging, and continuous CAN bus communication.

Linde’s Li-Ion Batteries and Chargers are Ideal for Every Kind of Application

State-of-the-Art Technology – High System Efficiency by Increasing Energy Yield by 30% Compared to Lead-Acid Batteries

Multi-level Safety Concept at Cell, Module, and Battery Level

Immediate and Fast Charging – Achieve Full Charge Cycle Within 1 Hour for Increased Truck Availability

Lean Charging Infrastructure – Enabling Efficient Set-up at Sensible Waypoints

Intelligent Battery Management – Seamless Alignment of Vehicle Control and Battery Management

Continuous CAN Bus Communication – Enabling a Completely Harmonized Overall System

Cost-Effectiveness

Li-ION batteries enhance fleet efficiency during operations due to their technological advantages, providing significant time and cost benefits for daily logistics and associated infrastructure.

High System Efficiency

The Li-ION solution from Linde has a particularly high degree of system efficiency. The combination of Linde Li-ION battery and Linde charger increases the energy yield by 30 percent compared to lead-acid batteries. This leads to lower energy costs.

Intelligent Battery Management

In addition, vehicle control and battery management are perfectly aligned – using CAN bus interface, for example – which enables systems to communicate with each other. The battery system is therefore able to balance peak loads while at the same time providing sufficient energy. This protects the battery and prolongs its operating life.

Reduced Maintenance and Handling costs

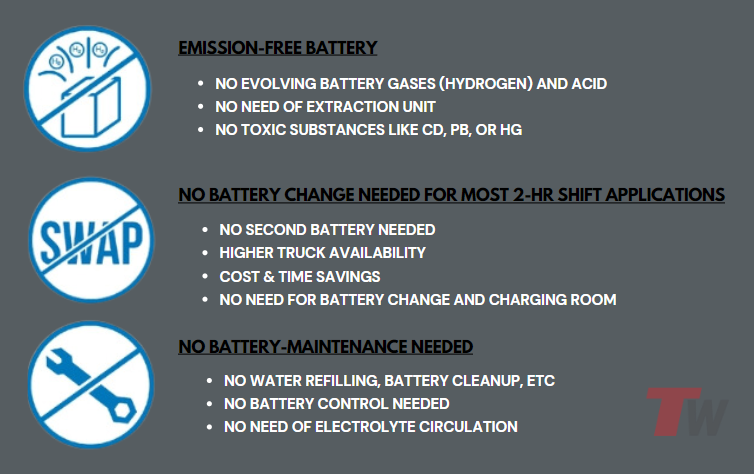

The use of conventional lead-acid batteries comes with a whole series of maintenance and handling costs, which are completely eliminated with Li-ION batteries. These include, for example, the cost of a second battery, personnel costs for replenishing the batteries with water and battery replacement.

Lean Charging Infrastructure

In addition, the complex charging infrastructure with separate battery room and suction device for the gases is a thing of the past. Instead, the charger for the Li-ION batteries can be set up as required at sensible waypoints, such as near break areas for quick recharging or in the application area to save on driving time.

Availability

For seamless logistics operations, optimal availability of warehouse equipment and forklifts is paramount. Linde’s Li-ION batteries excel in this regard, boasting high efficiency and flexibility in charging cycles and frequencies compared to traditional lead-acid batteries.

High Speed Charging

Linde batteries can be fully charged within just one hour, making them ideal for quick replenishment during lunch breaks. With this rapid recharge, vehicles are primed for several more hours of operation, ensuring continuous productivity.

Short Interim Charging Preferred

While conventional batteries require full charging cycles to safeguard their longevity, Li-ION batteries operate differently. Even brief, interim charges of just a few minutes are not only permissible but preferable. Maintaining these batteries between 20 to 80 percent of total capacity optimizes their performance, enhancing vehicle availability and flexibility in charging.

Customized Protection Against Deep Discharge

Linde’s CAN bus technology offers customizable settings to safeguard against deep discharge. When nearing minimum residual capacity, the battery management system for Li-ION batteries automatically adjusts drive and lift functions to preserve battery life. These settings can be tailored to meet the specific requirements of each customer, ensuring optimal balance between truck availability and battery protection.

Different Capacities for Different Applications

Linde provides flexibility with two capacity options for each battery type, allowing companies to tailor their vehicles’ energy supply to their specific operational needs. For instance, opting for the larger battery enables uninterrupted three-shift operation for forklift trucks without the need for charging during shifts.

Safety

Linde’s Li-ION technology prioritizes driver and vehicle safety at the highest level. Their engineers have meticulously crafted a comprehensive safety concept for both the battery and vehicle system, including rigorous stress and crash tests during the development phase.

No Hazardous Gases

Lead-acid batteries pose a risk of producing hazardous oxyhydrogen gas, whereas Li-ION batteries eliminate this danger. Furthermore, as lead-acid batteries do not require replacement, drivers are no longer exposed to injury risks. With virtually maintenance-free Li-ION cells, operators are not at risk of contact with hazardous acids.

Multi-Level Safety System

Linde’s Li-ION batteries feature a comprehensive multi-level safety system, operating at the cell, module, and battery levels. Battery management continuously monitors and coordinates vehicle functions, charging processes, and the battery system to ensure optimal usage and prevent damage from overpressure, overheating, over-charging, or deep discharge.

Moreover, the CE-compliance of both the vehicle and battery extends to the entire system, including the charger, ensuring tested safety across all components. This comprehensive safety assurance is not typically offered when purchasing the battery as a standalone component.

Sustainability

Linde’s cutting-edge energy systems not only excel in efficiency but also prioritize safety for both people and the environment. Our Li-ION batteries fulfill all sustainability standards, ensuring emission-free operation.

Furthermore, employing this technology in forklifts and warehouse equipment drastically enhances energy efficiency, achieving equivalent output with reduced energy consumption.

Extended Life Cycle

The manufacturing process of Li-ion batteries generates fewer pollutants compared to conventional lead-acid batteries. Additionally, the longer life cycle of Li-ion batteries contributes to the conservation of environmental resources.

Comprehensive Recycling Process

Linde is committed to sustainability extends from battery production to end-of-life recycling. When Li-ION batteries reach the end of their service life, they can be returned to any Linde network service partner. These batteries are then sent to certified recycling facilities, where they undergo comprehensive recycling processes.

During recycling, batteries are disassembled, and components are sorted. Electronic parts and cables are recycled conventionally, while battery cells are melted down and metallurgically processed to recover valuable elements such as lithium, cobalt, and nickel. Through this integrated approach, Linde stands as a pioneering force in intralogistics Li-ION battery recycling.

Characteristics of Linde’s Li-Ion Batteries and Chargers

At Total Warehouse, we can ensure that the process of converting to lithium-ion is extremely easy so that you can explore the advantages of Li-Ion Batteries and Chargers. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.