Key Features

Compliance Backed by Certification

Our professionals are trained, certified, and fully insured, ensuring you receive quality care at every job site. We maintain all necessary credentials for national and local compliance.

- Certified rack installation experts

- Fully bonded and insured

- Nationwide licensing coverage

- Regular training on safety and specs

Learn More: Total Warehouse Rack Installation

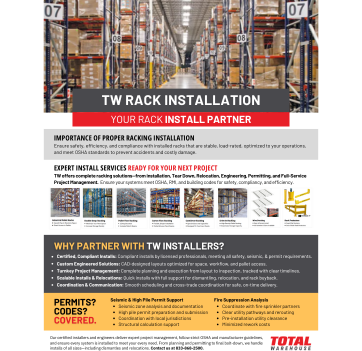

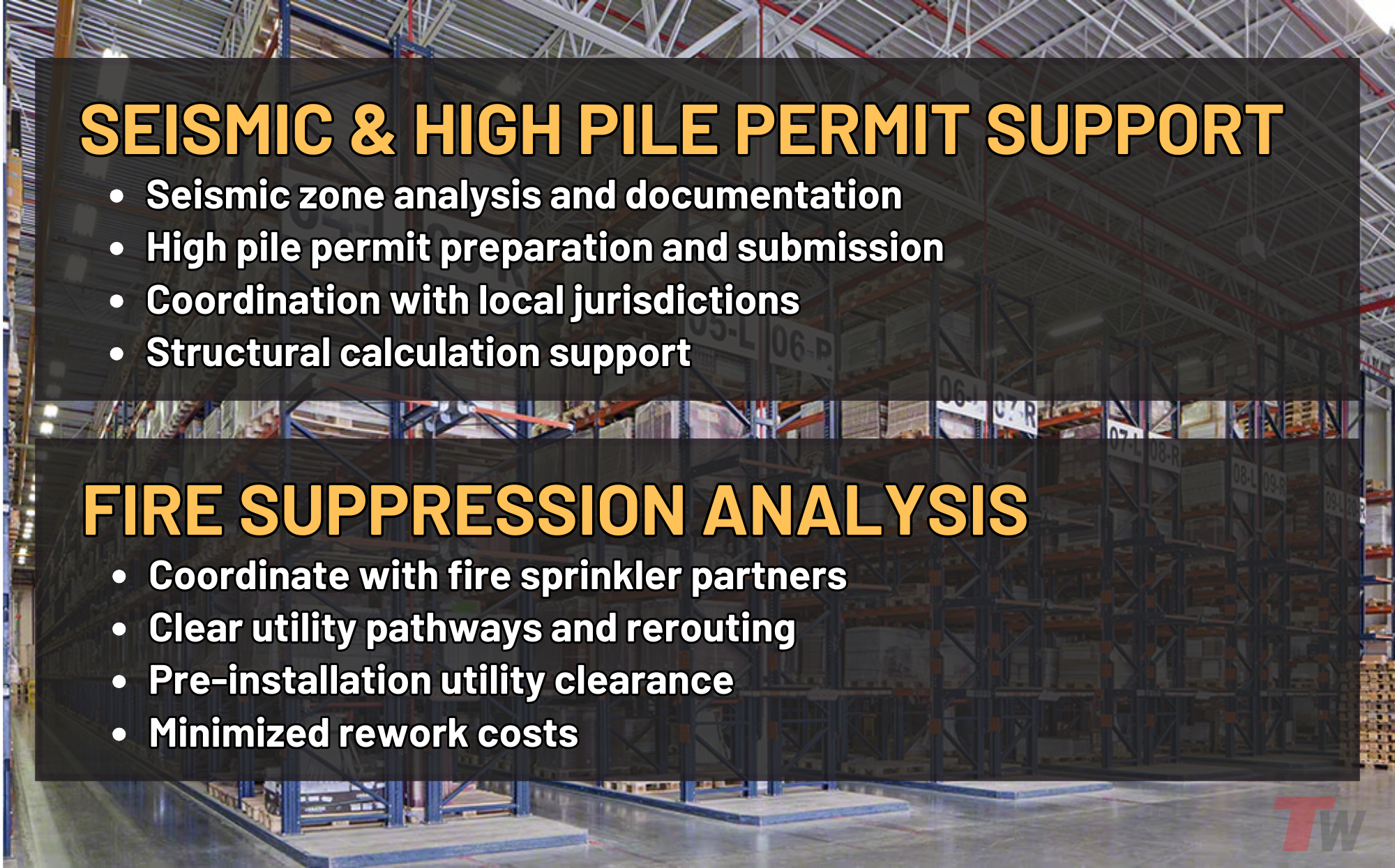

Permits. Codes. Covered.

Our team handles city permits, seismic analysis, and fire code regulations to protect your investment. You won’t need to chase approvals—we bring them to you.

- High pile permits and fire code clearance

- Seismic zone requirements

- Signed-off engineering drawings

Built to Scale with You

Whether you’re adding 10 bays or 100, our racking installs grow with your business. Our modular solutions adapt as your inventory and space needs change.

- Pallet racking, cantilever, high-density, and more

- Compatible with existing systems

- Future-proofed installations

Your Space. Our Responsibility.

When it’s time to relocate or refresh, we dismantle safely, cleanly, and quickly. We respect your workspace and limit disruption.

- Debris removal and equipment handling

- Labeled, packed, and stored materials

- PPE and site protection compliance

Wherever You Grow, We Go.

We support multi-site rollouts and corporate compliance standards across the entire West Coast. Our teams are experienced with both regional builds and national warehouse chains.

- Consistent installs across facilities

- Familiar with corporate vendor protocols

- Centralized communication

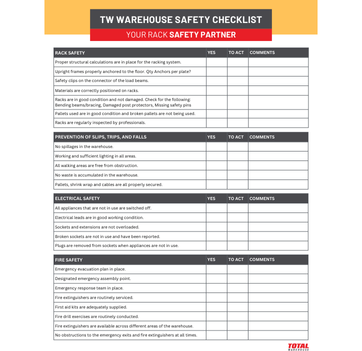

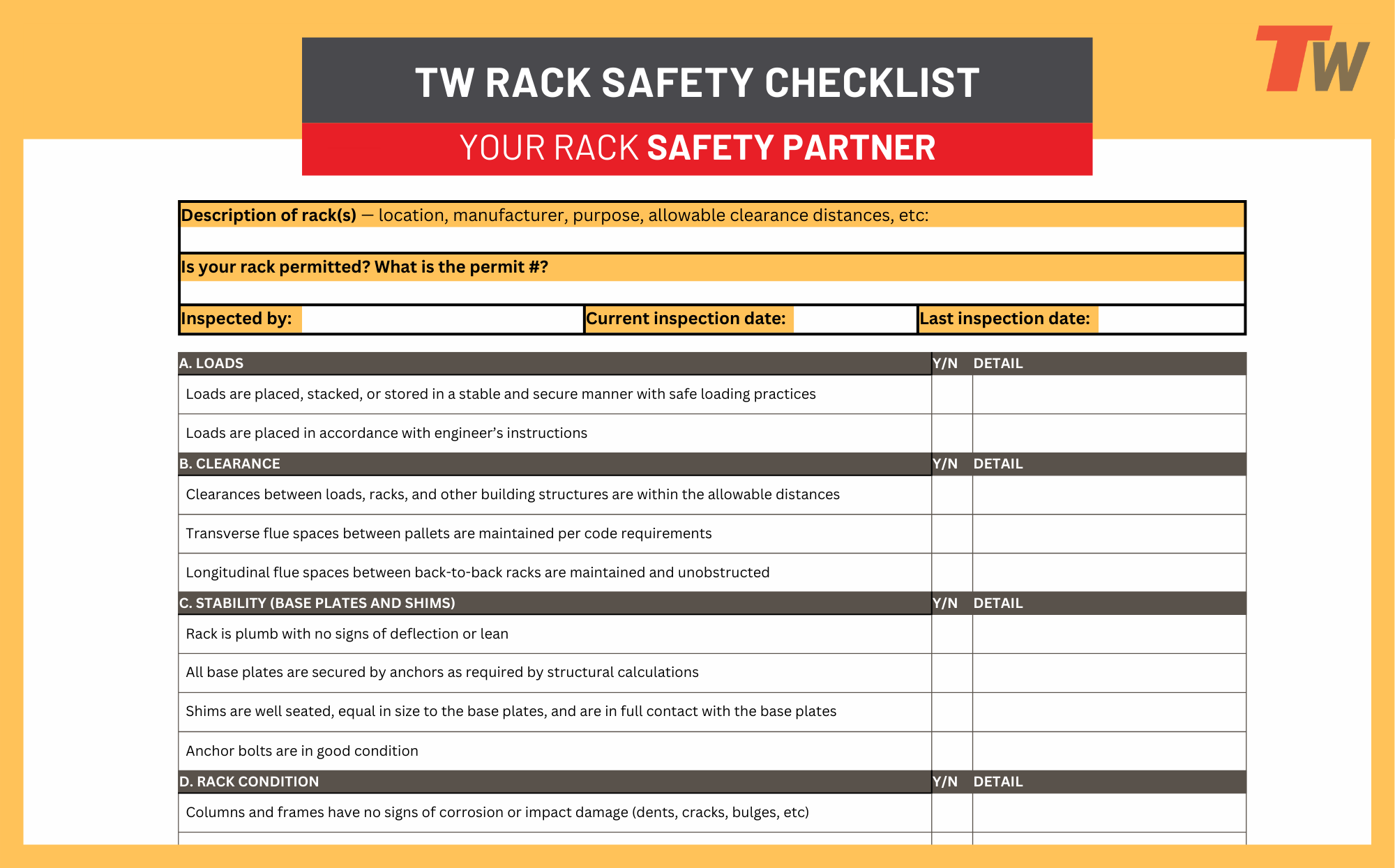

Inspected for Safety, Installed for Excellence

TW installation delivers expert, compliant setup tailored to your warehouse needs. Our Rack Inspection Checklist ensures every system meets every safety and quality standard.

- Professional Installation: Certified installers ensure correct assembly and anchoring.

- Safety Compliance: Installations meet OSHA, RMI, and local regulations.

- Quality Assurance: Pre and Post inspections confirm structural integrity and quality.

- Operational Readiness: Systems are ready for immediate and safe use.

Learn More: TW Rack Inspection Checklist

📦 Pallet Rack Installation FAQ

1. Why is proper pallet rack installation so important?

Proper installation ensures the safety of your employees, prevents product damage, and maximizes the efficiency and lifespan of your racking system.

2. When should I start planning for pallet racking in a new warehouse?

As early as possible. Planning ahead helps avoid delays due to long lead times for permits, manufacturing, and installation scheduling.

3. Do I need permits for pallet racking?

Yes—racks over 5’9″ require permits. Depending on your location and product type, you may also fall under high-pile storage regulations.

4. How long does the permit process take?

The typical permit process takes 6–8 weeks, but can extend to 2–8 months if fire safety or sprinkler upgrades are required.

5. What are high-pile storage requirements?

If you’re storing product over 12 feet, your racking may need additional fire suppression measures and code compliance to pass inspection.

6. What is included in the pre-installation process?

We inspect materials, verify plans, flag obstructions, confirm floor conditions, and ensure the crew is trained on safety and procedures.

7. How thick should the warehouse floor slab be for pallet racks?

Typically, a 6-inch concrete slab is required to support standard pallet racking systems.

8. How long does it take to manufacture pallet racking?

Lead times range from 2 to 12 weeks depending on order size and whether standard or custom racking is needed.

9. Should I order racking before permits are approved?

Ideally, no. Ordering before permit approval carries risk—denial may require costly adjustments to racking or your building’s sprinkler system.

10. How long does installation take?

Most small-to-medium jobs take 2–4 weeks, though larger projects or limited installer availability can extend this timeline.

11. What is a special inspection?

A special inspection checks pallet rack anchors for compliance and safety. It usually takes place within 1–3 days of installation.

12. What happens during the final inspection?

After passing the special inspection, the city/county will conduct a final review to approve your permit and clear your racking for use.

13. What does a typical rack installation crew look like?

We use a trained team of 3–5 certified professionals who follow OSHA standards, manufacturer specs, and project-specific guidelines.

14. What can delay my racking project?

Common delays include permit denials, missing documentation, backordered materials, or uncovered building compliance issues.

15. Why choose Total Warehouse for rack installation?

We provide turnkey service with certified installers, OSHA-compliant practices, project management, equipment operation, and ongoing communication—all with safety, quality, and efficiency in mind.

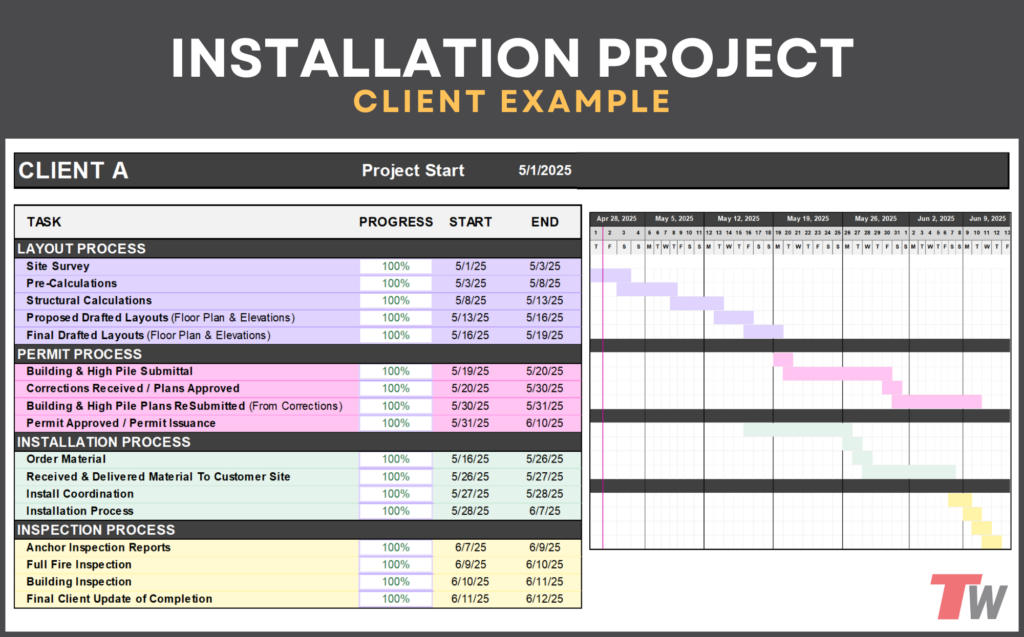

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

Optimize Your Warehouse

By TW Installation

Partnering with clients for 50+ years, our in-house engineering and install experts help businesses maximize space, efficiency, and pallet positions with professional installation and implementation of storage systems.

- Certified and Licensed Professionals

- Ensure OSHA-Compliant Rack Systems

- Project Management Services for All Installations

- Permit Submittal & Acquisition

- Ensure Adherence to OSHA Guidelines

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.