Key Features

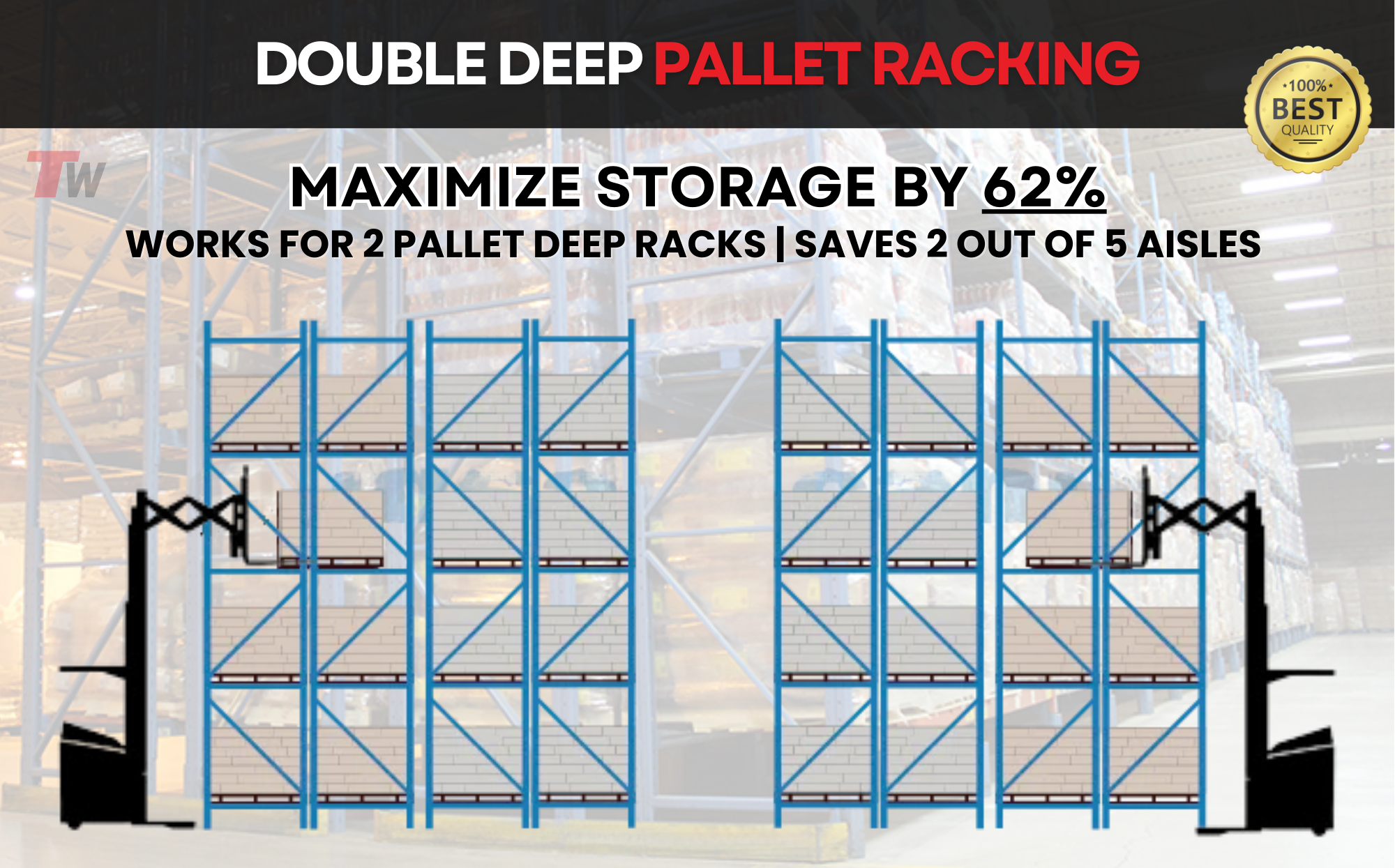

Maximize Your Storage Density

Double deep racking delivers high-density storage and efficient handling for operations storing multiple pallets per SKU.

- Stores pallets two-deep to significantly increase storage capacity

- Scalable vertically and horizontally to fit any warehouse footprint

- Adapts easily to various pallet sizes and load heights

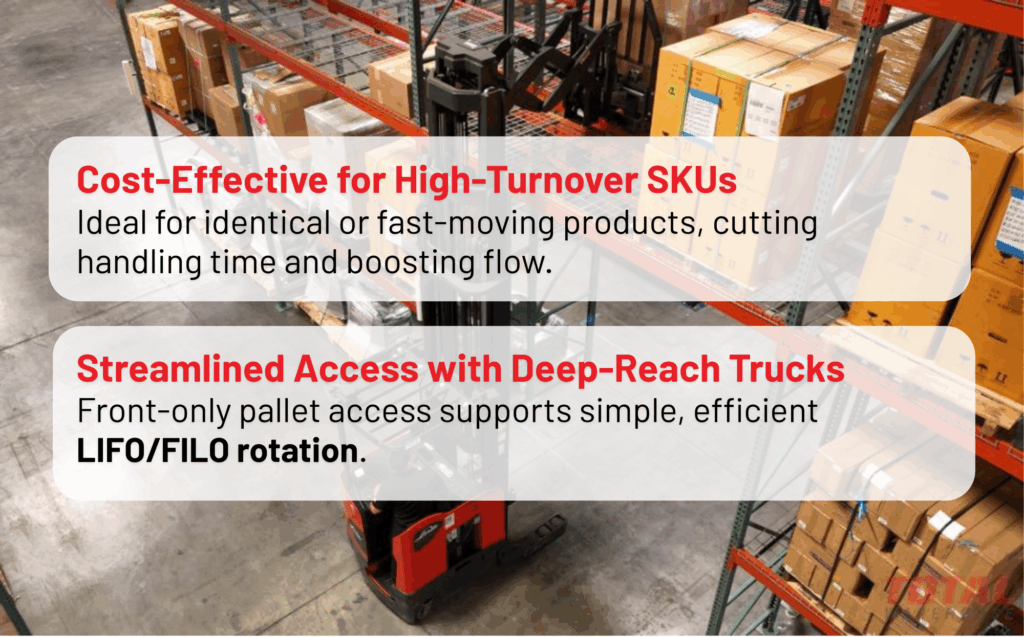

- Ideal for LIFO/FILO inventory systems and high-turnover, uniform products

Partner with Total Warehouse: We’ll design a customized double deep racking system that safely optimizes your storage density, workflow, and long-term growth.

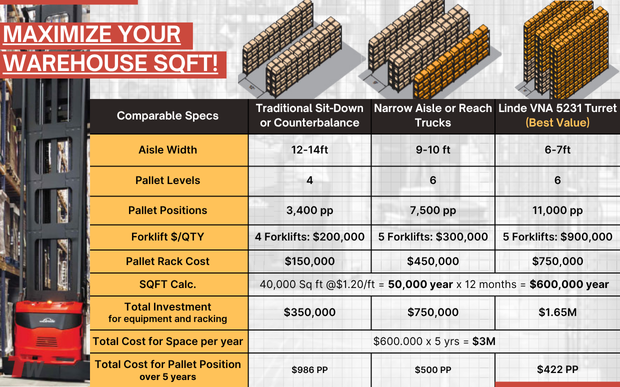

TW Engineered Solutions

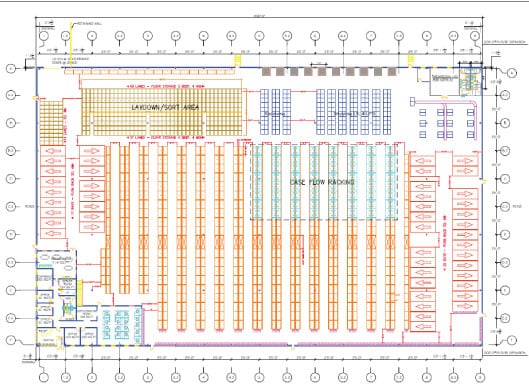

Our experts design personalized, expert solutions to optimize your storage space.

- We Analyze Your Space & Load Requirements

- We Perform Comprehensive Seismic Calculations

- We Provide Detailed CAD Designs for Tailored Rack Systems

- Receive a Comprehensive Site Analysis

- We Match BEST EQT Utilization for Maximizing Space

Learn More: TW Engineers

Turn Aisle Space into Storage Space

Double deep racking reduces the number of aisles needed and boosts warehouse capacity up to 65% without expanding the footprint.

- Fewer Aisles: Frees up space for more pallet positions.

- Higher Density: 2x pallet storage capacity within the same footprint.

- Optimized Layout: More space efficiency for high-demand storage environments.

- Better Space Use: Ideal for facilities with limited square footage.

- Increased Capacity: Up to 65% more storage than single-deep racks.

Safeguard Your Storage

Our experts ensure that double deep racking is a safe, high-density storage solution for heavy loads when properly designed, installed, and maintained according to manufacturer specifications and safety standards.

- Load Limits Adherence – Stay within manufacturer-rated beam & upright capacities.

- Ensure Structural Integrity – Use high-strength steel construction for durability

- Use Proper Equipment – Operate with deep reach trucks to load and extract pallets

- Maintain Regularly – Conduct routine inspections and repairs to uphold safety

- Stay Compliant – Follow OSHA and relevant warehouse safety regulations

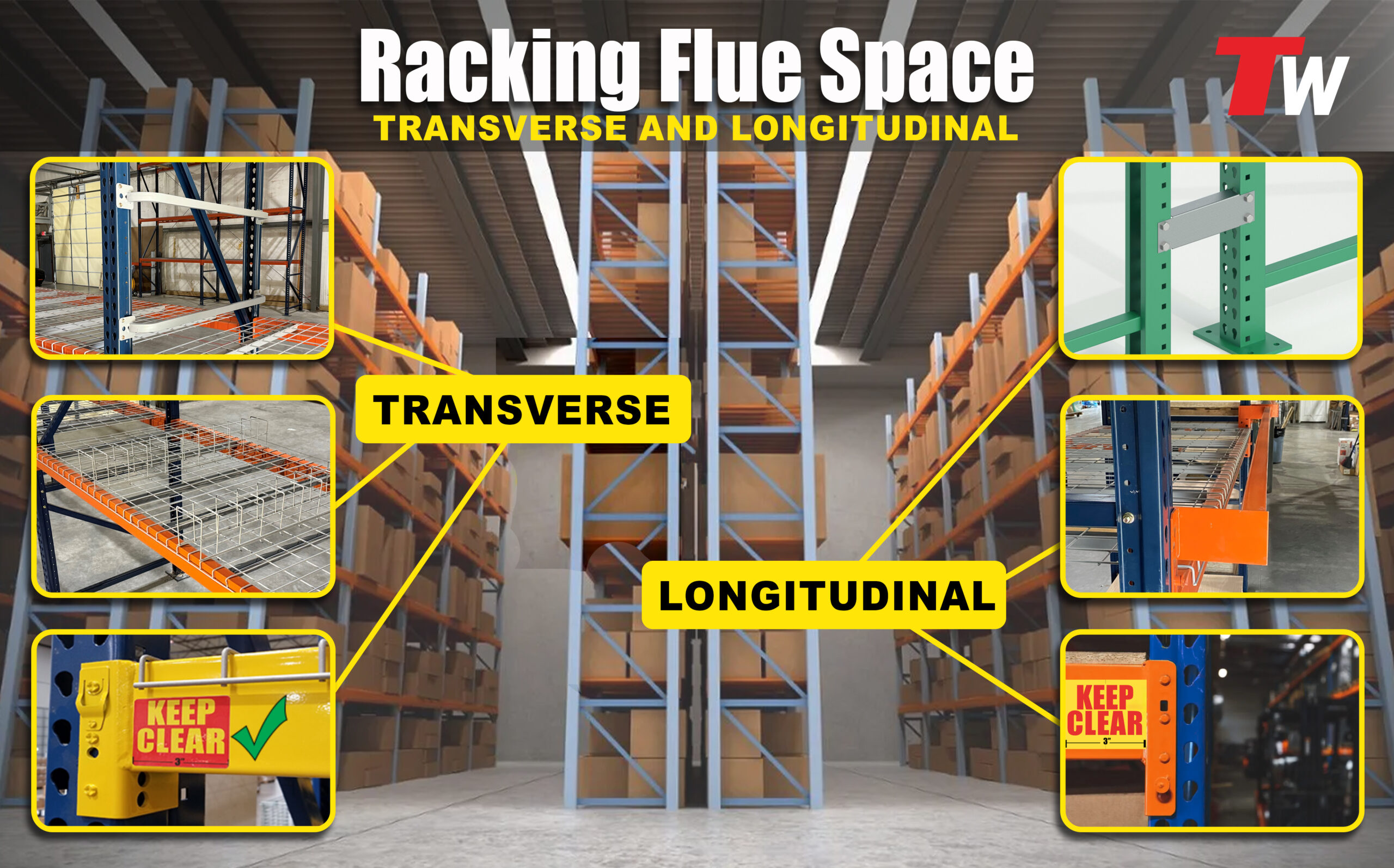

Flue Space Optimization

Proper transverse and longitudinal flue spacing is essential for fire safety and sprinkler performance. Our layouts ensure code-compliant spacing, using tools like indicator bars and labels to maintain clearances and support NFPA requirements.

- Transverse Spacing: Between pallets side-to-side

- Longitudinal spacing: Between rack rows front-to-back

- Supports NFPA and local fire codes

- Enhances sprinkler coverage and emergency response

- Reduces risk of blocked water distribution

Learn More: Pallet Rack Flue Space

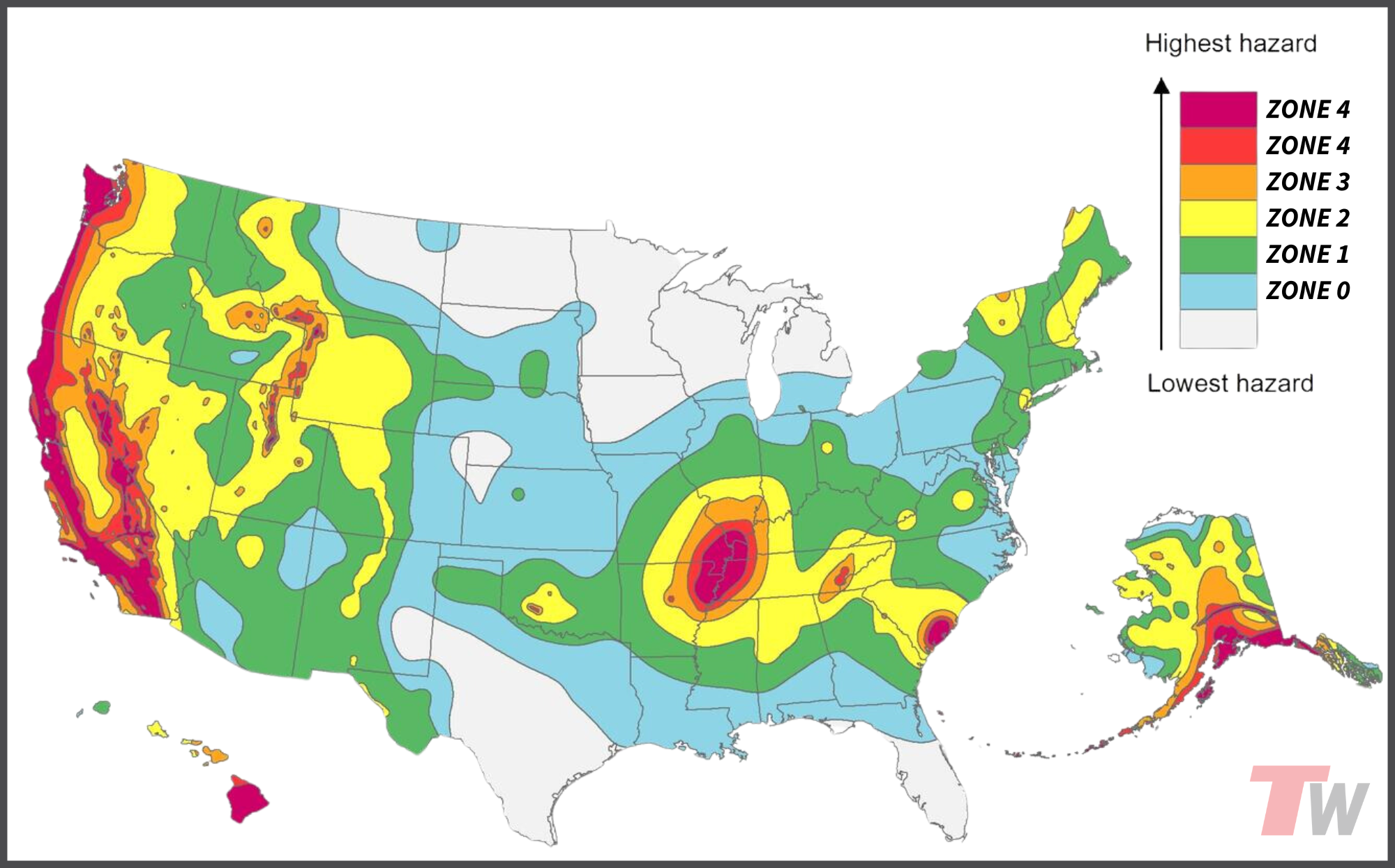

Seismic Engineering & Structural/Building Permits

Seismic zones dictate the earthquake resistance required for safe, compliant racking. We provide structural and seismic calculations to prevent collapse, protect inventory and staff, and minimize downtime in your area.

TW Engineering & Design Experts Provide:

- Seismic-compliant racking with structural analysis

- Code-compliant, permit-ready documentation

- Full support with permit submittals and regulatory compliance

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

Double Deep Value

Provides 30-40% more pallet locations compared to single entry shelving, while ensuring 50% product accessibility at all times. Its compact design optimizes warehouse space, striking a favorable balance between storage capacity and accessibility.

- Best Floor Space Usage with Strong Aisle/Shelving Ratio

- Keep Product Lines Together by Storing 2 Pallets Deep

- Increase storage density by around 30-40%

- Cost-effective Racking Configuration

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.