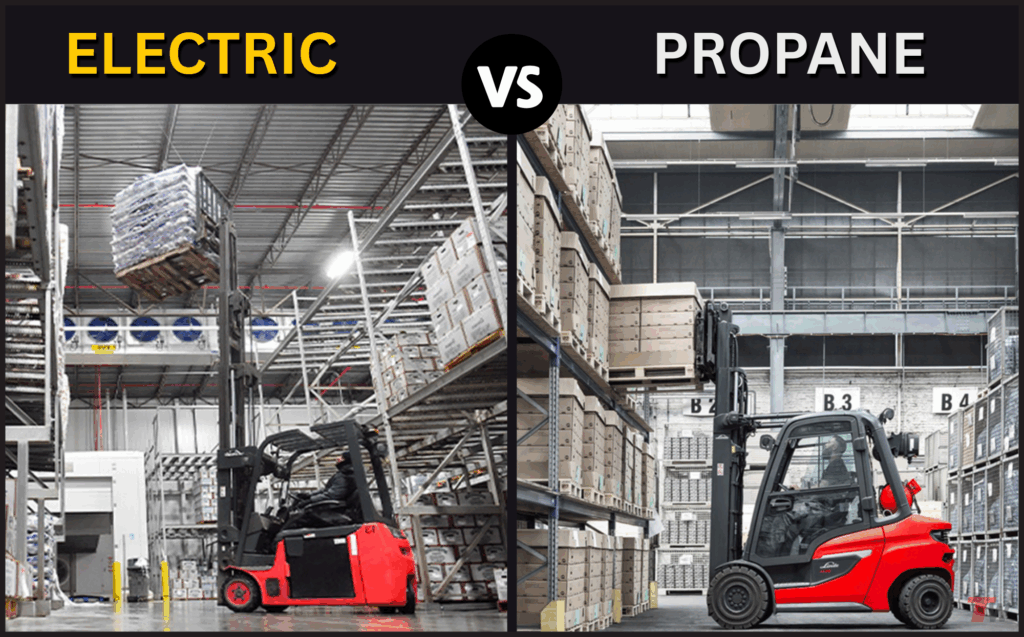

Electric vs Internal Combustion IC Forklifts: Which is Right for Your Operation?

One of the most common questions in material handling today is: Electric Forklifts vs Internal Combustion (IC) Forklifts — which should I choose? Selecting the right forklift for your specific application can save time, reduce costs, and improve efficiency. Because work environments and operational needs vary widely, it’s essential to evaluate your unique situation carefully. Total Warehouse offers expert guidance to help you make the best choice for your business.

⚡Electric Forklifts

Applications: Electric forklifts are preferred for indoor environments due to zero emissions. Many models feature sealed motors and controllers that allow outdoor use in certain conditions.

Advantages:

- Produce zero emissions, improving indoor air quality

- Lower maintenance costs with fewer moving parts

- Longer economic lifespan and quieter operation

- Lower fueling costs as they run on electricity

- Smaller aisle width requirements, enhancing maneuverability

Disadvantages:

- Higher initial investment

- Limited availability for models over 15,000 lbs. capacity

- Require battery changing stations and trained staff for battery maintenance

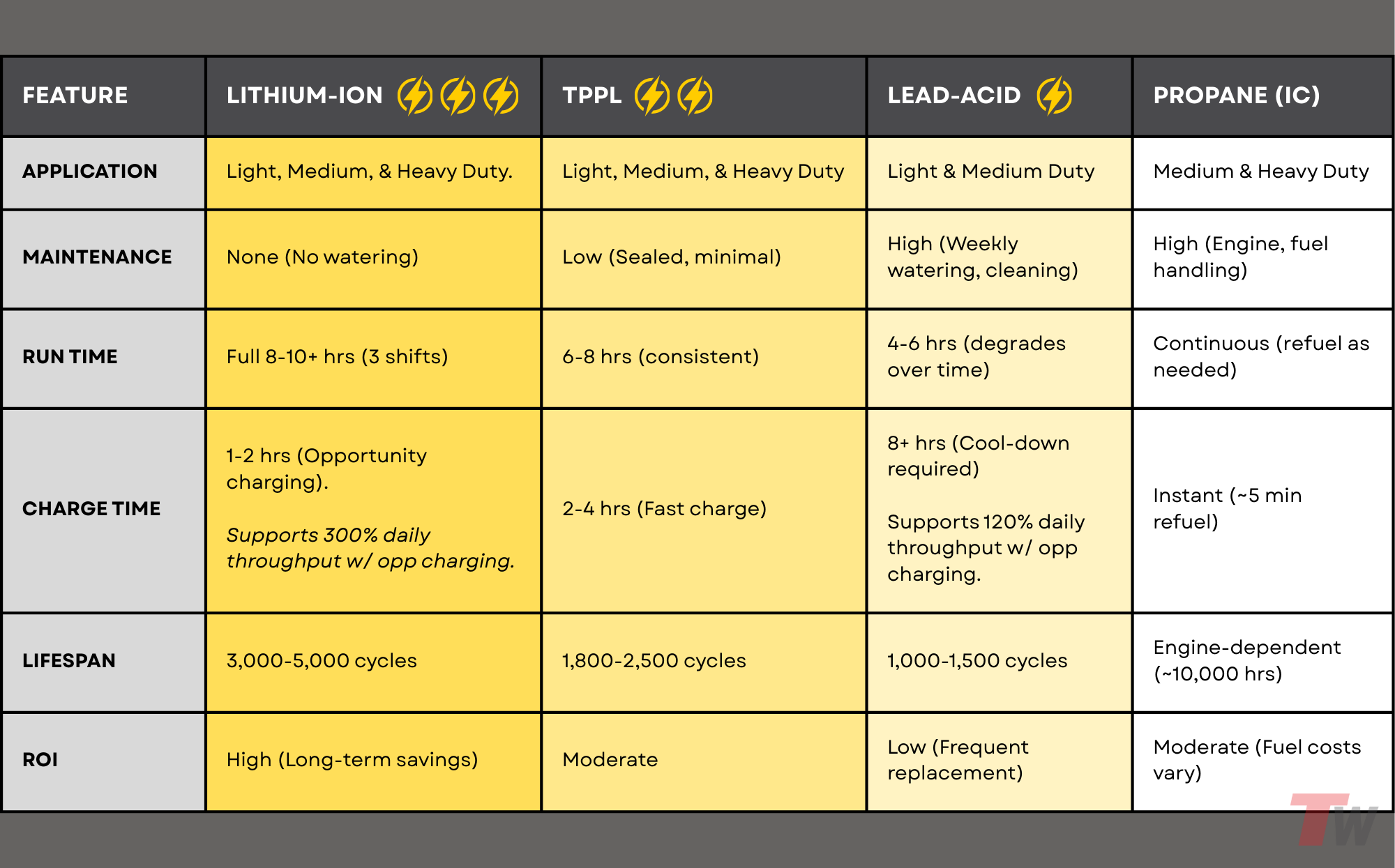

Recharging and Efficiency: Electric forklift batteries typically take 8 hours to recharge plus additional cooling time, so operations with multiple shifts may need extra batteries or vehicles. Total Warehouse offers energy-efficient electric forklifts that can run up to two shifts on a single battery charge, helping you save time and reduce expenses on batteries and chargers.

Fuel and Maintenance Savings: Electric forklifts operate on electricity, reducing fuel expenses significantly. Maintenance costs are generally lower because electric trucks have fewer components needing repair.

Learn More: Electric Forklift Solutions with Lithium-Ion, TPPL, & Lead-Acid Batteries

⛽ Internal Combustion Forklifts

Applications: Ideal for outdoor use, internal combustion (IC) forklifts powered by diesel, gasoline, or compressed natural gas are robust machines designed to handle tough jobs. Propane-fueled IC forklifts can also be used indoors with proper ventilation.

Advantages:

- Lower upfront cost compared to electric forklifts

- Superior for long runs, ramps, and high-speed applications

- Heavy lifting capacity exceeding 35,000 lbs.

- Quick refueling—simply swap propane tanks or refill gas/diesel

Disadvantages:

- Require well-ventilated indoor environments due to emissions

- Higher maintenance needs including regular engine checks

- Higher fueling costs over time

Refueling and Maintenance: The main advantage of IC forklifts is the ability to refuel quickly, minimizing downtime during shifts. However, they demand regular engine maintenance such as oil changes and spark plug replacements. These upkeep tasks can lead to higher maintenance costs compared to electric models.

Performance: IC forklifts excel in heavy-duty applications like brick and lumber yards, where lifting power and durability are critical. Recent electric forklift advancements are bridging the gap, making electric models viable for more outdoor uses.

Electric vs IC Forklifts: Pros and Cons at a Glance

⚡Electric Forklift Pros:

- Battery costs are declining, with lithium-ion technology enabling quicker charging and multi-shift use without battery swaps

- Up to 75% less expensive to operate than propane forklifts

- Easier maintenance due to fewer moving parts and tight turning radius for compact spaces

- Increasingly suitable for outdoor use with protected components

⚡Electric Forklift Cons:

- Higher upfront cost than IC models

- Multi-shift operations require multiple vehicles or extra batteries and charging infrastructure

- Requires technical skill for installation and battery maintenance

- Additional space needed for battery charging and storage

⛽IC Forklift Pros:

- Suitable for indoor (with ventilation) and outdoor applications

- Potentially lower total operating costs for multi-shift use

- Quick refueling by swapping propane tanks minimizes downtime

- Requires less storage space for fuel compared to electric battery systems

⛽IC Forklift Cons:

- Regular engine maintenance needed, increasing operational complexity

- Generates waste such as engine oil and transmission fluids that require proper disposal

Let Total Warehouse Help You Decide

Choosing between electric forklifts vs internal combustion forklifts depends on your facility’s needs, application, and budget. Our experienced material handling experts are ready to provide tailored recommendations and supply the best forklift solutions to maximize your operational efficiency. Contact Total Warehouse today to explore our comprehensive range of forklifts and learn which model is right for your business.

Raising the Bar for Reliability — The Total Warehouse Standard

Total Warehouse are proud dealers for EnerSys, Dematic, Linde, Big Joe, UniCarriers, and Landoll. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.