Order Picking Solutions in Narrow Aisles: Equipment, Strategies & Safety

Order picking is the backbone of warehouse operations — but when space is limited, efficiency and safety become even more critical. Warehouses with tight aisles or very narrow aisle (VNA) configurations must rely on specialized equipment and smart strategies to maintain throughput without sacrificing safety. At Total Warehouse, we specialize in solutions that help businesses optimize storage density, improve picking speed, and maximize ROI in space-constrained environments.

Learn More: Total Warehouse Equipment

Specialized Equipment for Tight Aisles

1. Order Pickers Order Picking Solutions

Order pickers are designed for operators to ride up with the forks and access products directly at shelving height. This direct access reduces pick times, improves accuracy, and allows for safer retrieval in tall racks. In narrow aisles, their compact turning radius makes them highly maneuverable.

Learn More: Linde VNA 5231

2. Turret Trucks (VNA Forklifts) Order Picking Solution

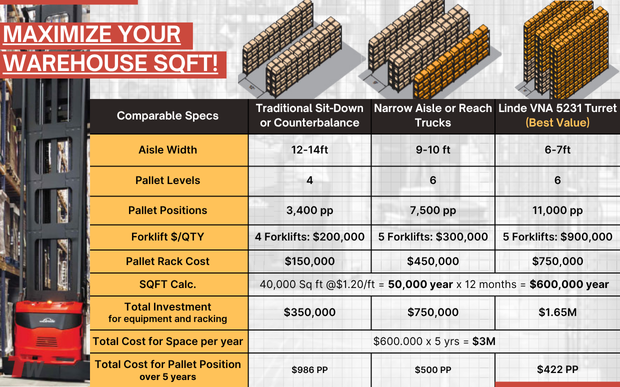

Also known as very narrow aisle trucks, turret trucks feature forks that rotate up to 90 degrees, enabling operators to pick from either side of the aisle without turning the vehicle. This capability allows aisles to be built narrower while still providing full product access — a major advantage in high-density storage facilities.

Learn More: Linde VNA 5231

3. Reach Trucks Order Picking Solutions

Reach trucks are versatile solutions for narrow aisles, particularly for high-bay storage. Their extendable forks allow operators to “reach” deep into racking systems, making them perfect for warehouses where vertical storage is key.

Learn More: Linde 5195

4. Wire Guidance Systems

Many narrow aisle forklifts incorporate wire guidance systems. Embedded wires in the floor communicate with sensors on the truck, automating steering and reducing operator fatigue. This allows trucks to operate with minimal clearance, maximizing usable storage space while enhancing precision.

Learn More: Smart Wire Guidance System

5. Pedestrian Stackers

For lower-level picking in very tight spaces, pedestrian stackers are a cost-effective and agile solution. Their small footprint and maneuverability make them ideal for smaller warehouses or secondary storage areas.

Learn More: Big Joe S22 & S30

Strategies & Best Practices for Tight Aisle Picking

Leverage Mobile Technology

Technologies like pick-to-light, RF scanners, and pick-to-voice systems streamline operator workflows by guiding them directly to the correct pick location. This reduces errors and increases pick speed, which is essential in high-SKU operations such as e-commerce fulfillment.

Implement Efficient Picking Methods

Strategies like pick-and-pass — where orders are divided into zones and passed between operators — can significantly improve workflow efficiency. This reduces congestion in tight aisles and keeps picking operations moving smoothly.

Prioritize Operator Safety

In tight aisle applications, operator safety is paramount. OSHA requires operators using order pickers to wear safety harnesses and lanyards secured to the lift truck at all times. Regular training, fall protection equipment, and adherence to safety protocols protect both workers and operations.

Optimize Warehouse Design

A well-planned warehouse layout can make or break tight aisle efficiency. By designing aisles to accommodate specific equipment (e.g., turret trucks or wire-guided systems), businesses can maximize storage density while maintaining safe traffic flow. Slotting strategies — organizing SKUs based on demand frequency — further reduce wasted travel time.

Scale with Flexibility

Consider hybrid solutions that combine equipment types, such as pairing turret trucks for high-volume picking with stackers for smaller tasks. This allows operations to stay agile and adapt to seasonal surges or SKU growth.

Why Tight Aisle Solutions Are Growing in Demand

With the rise of e-commerce, 3PL logistics, and urban fulfillment centers, the demand for narrow aisle and VNA solutions is increasing. Real estate costs are climbing, and maximizing every square foot of storage has become essential. By investing in the right equipment and operational strategies, businesses can increase storage capacity by up to 40% without moving to a larger facility.

At Total Warehouse, we partner with global leaders like Linde Material Handling to deliver advanced narrow aisle forklifts, order pickers, and turret trucks, all backed by service, training, and fleet management solutions tailored to your needs.

Final Thoughts

Order picking in tight aisles doesn’t need to slow your business down. With the right combination of specialized equipment, advanced technologies, and smart warehouse design, companies can turn tight spaces into high-performance, high-density operations with our order picking solutions.

If you’re ready to optimize your warehouse, Total Warehouse can help with equipment selection, layout consultation, and ongoing support. Contact us today to explore how our order picking solutions can transform your operation.

Looking for the Best Linde Forklift for Your Fleet?

At Total Warehouse, we specialize in Linde forklifts to help you boost productivity and efficiency. Contact us today to explore our Linde forklift options and schedule a demo!

Total Warehouse are proud dealers for Linde, Big Joe, UniCarriers, Landoll. and Dematic. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.