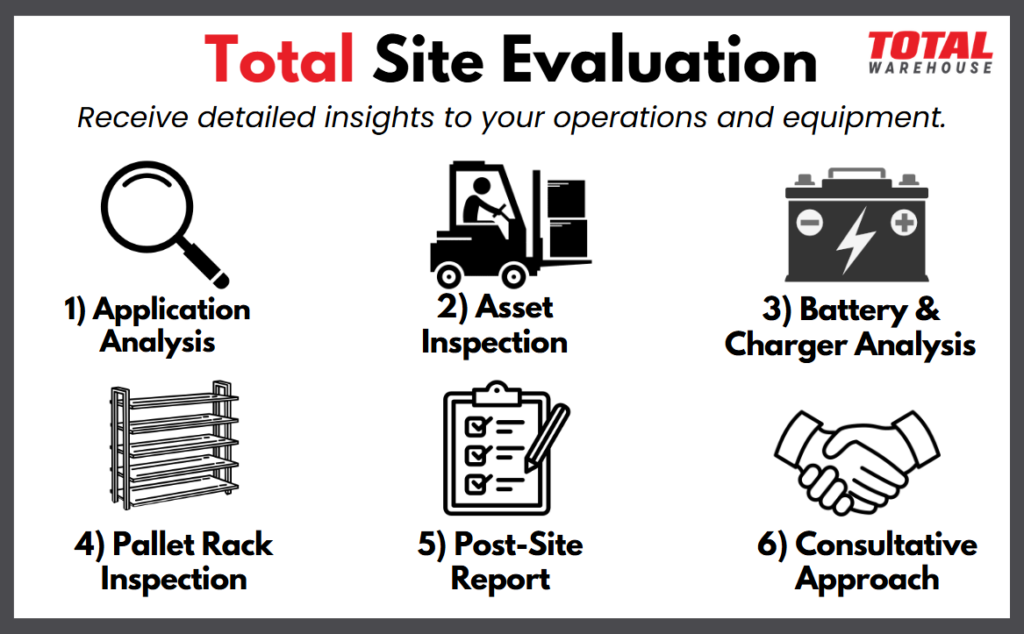

6 TW Strategic Steps

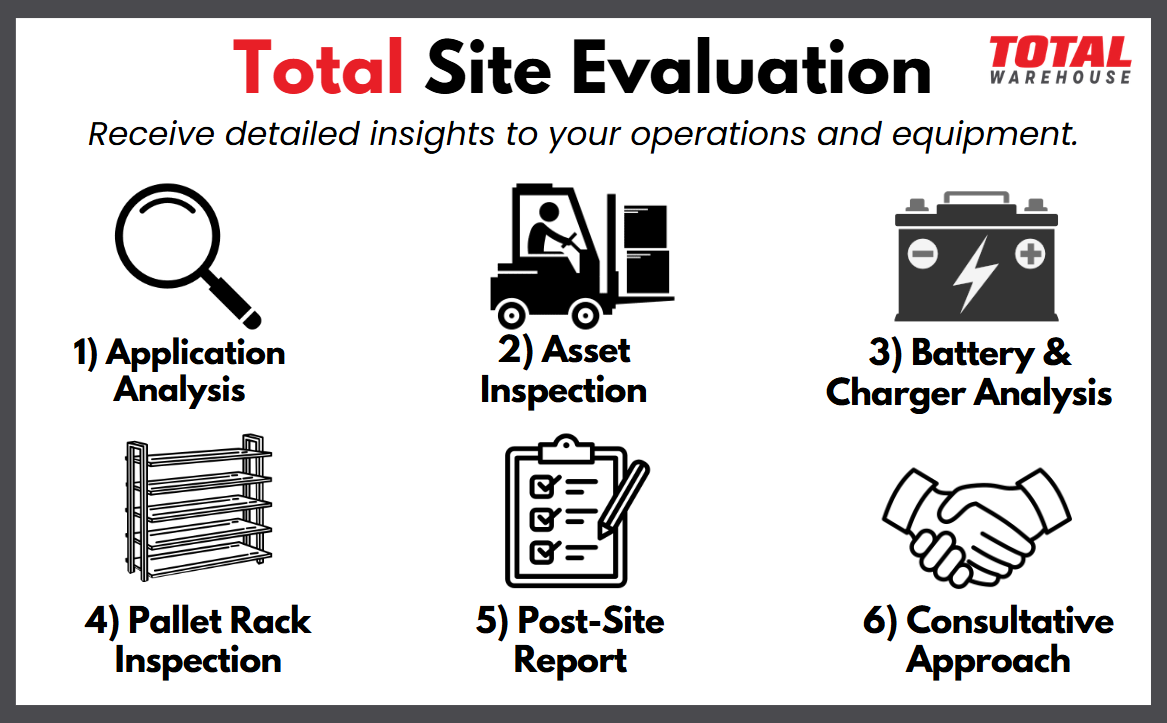

Comprehensive Application Analysis

We examine your operation’s size, workflows, equipment usage, product, and activity trends to understand your operational demands.

Why it matters:

- Identifies equipment overuse or underuse

- Helps define right-size fleet composition

Warehouse Application Analytics

- Analyze warehouse systems, inventory processes, and workflows

- Evaluate space utilization and layout efficiency

- Review picking, packing, and order fulfillment procedures

- Identify opportunities for operational improvements and cost savings

Detailed Current Fleet Analysis

This includes age, service history, hours of use, and performance metrics to assess each unit’s health and value.

Why It matters:

- Uncovers high-maintenance or outdated units

- Establishes a baseline for future upgrades or replacements

- Maximizes the full lifecycle and uptime of every forklift in your fleet

Equipment Lifecycle

- Track each unit through usage, maintenance, and End-of-Life

- Reduce downtime and optimize ROI with strategic fleet planning

- ALWAYS Know When to Extend, Recondition, Resell, or Dispose.

Comprehensive Battery & Charger Analysis

We evaluate your current power system setup, including charge times, battery rotation, charger compatibility, and storage environment.

Why it matters:

- Reduces downtime and costs from battery-related issues

- Extends battery life and ensures energy-efficient charging

Power & Energy Analytics

- Analyze battery & charger specifications and conduct testing & analysis

- Review regular maintenance and inspection schedule

- Ensure safe charging environment and emergency equipment

Learn More: TW Energy Solutions

Storage Space & Racking System Analysis

We inspect your pallet racking systems for compliancy, hidden damage, layout inefficiencies, and capacity mismatches.

Why it matters:

- Enhances operator safety, compliancy, and reduced risk of costly racking failures

- Supports smoother, faster order picking and replenishment

Storage Space Assessment

- Analyze space and load requirements for structural, legal, and operational standards

- Review city permits, seismic analysis, and fire code regulations

- Review path of egress, flue space, fire safety equipment, etc.

Learn More: TW Engineering

Post-Site Evaluation & Recommendations

After evaluations, we deliver a clear, actionable post-site report with condition summaries, fleet metrics, safety issues, and cost-saving opportunities tailored to your warehouse.

Why it matters:

- Gives stakeholders a snapshot of current challenges and opportunities

- Prioritizes recommendations for maximum ROI

- Sets up your team with a data-driven action plan

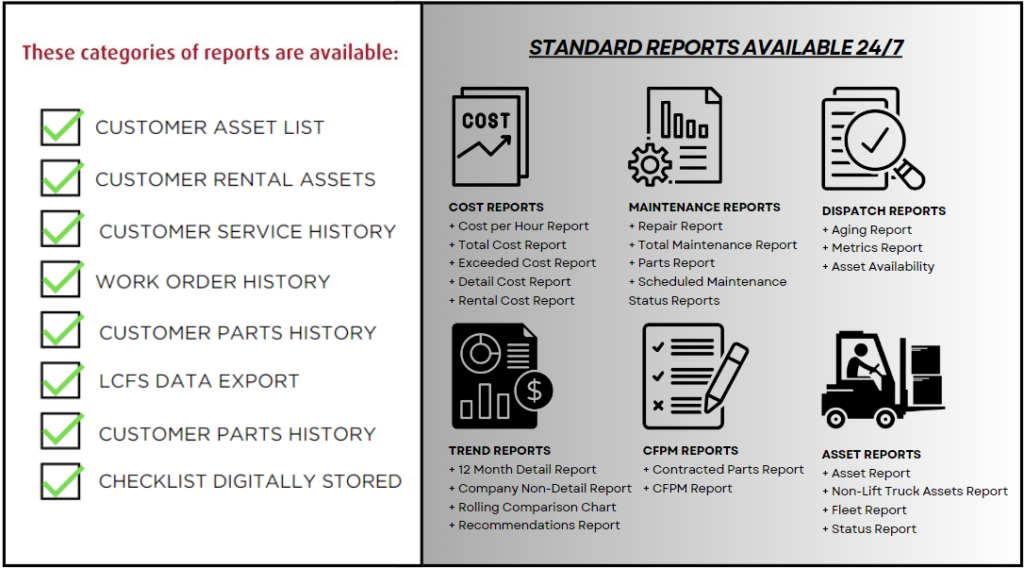

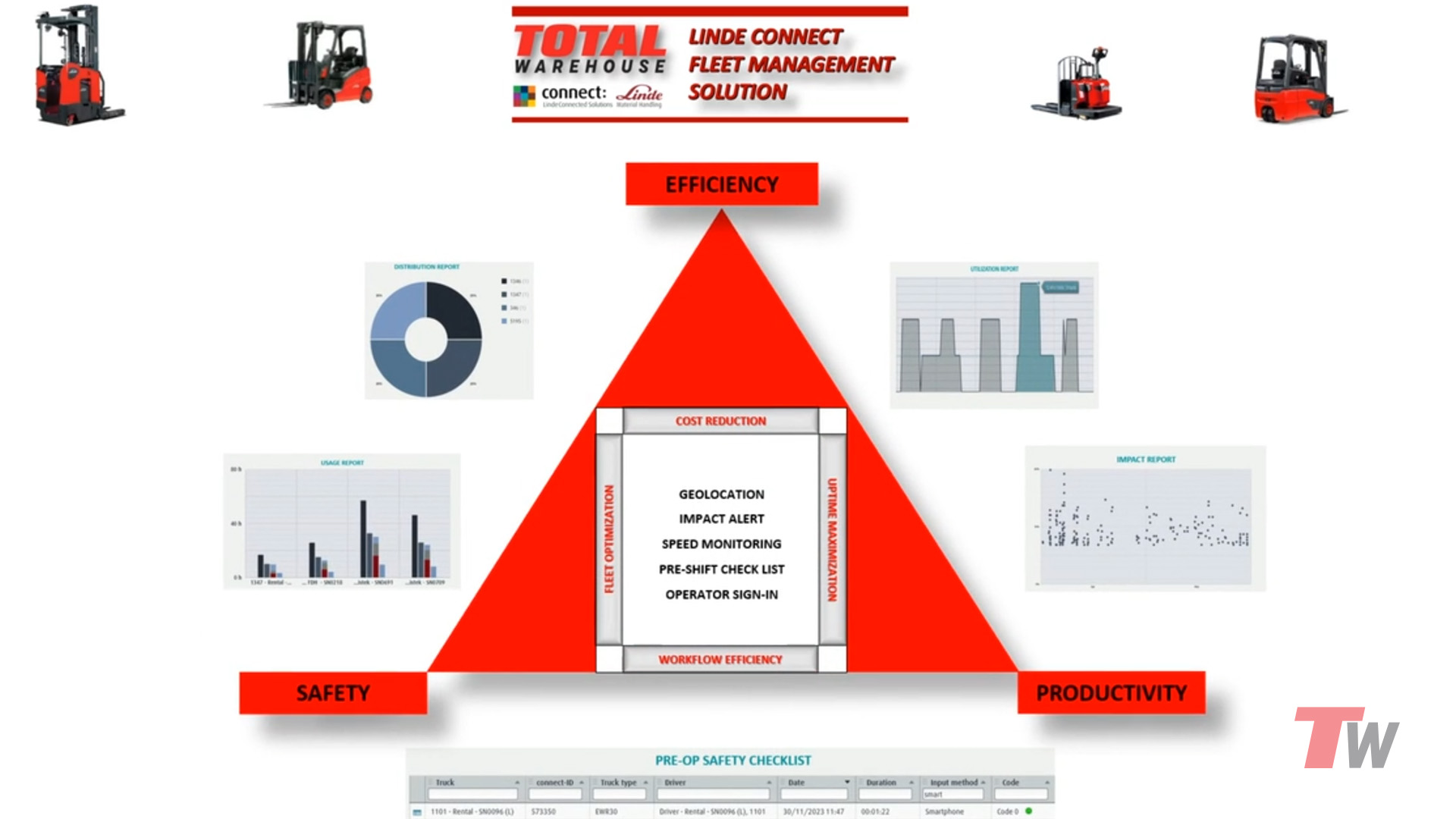

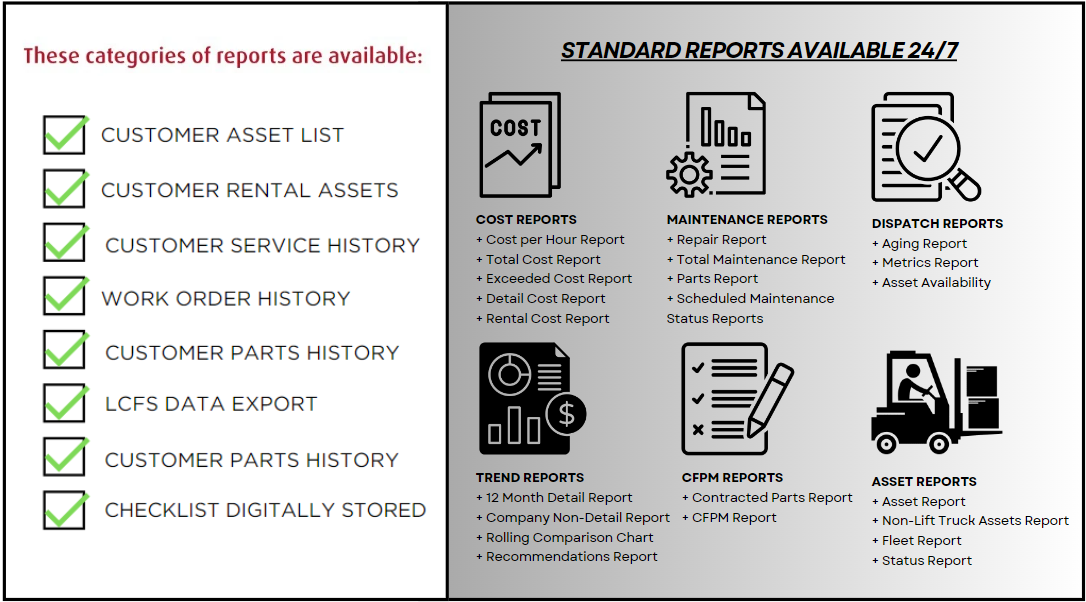

Strategic Partners for Continued Improvement

Total Warehouse is your strategic partner, providing ongoing support with equipment replacement, telematics integration, fleet tracking, and service maintenance.

- Monitor multiple sites simultaneously

- View service trends, history, and asset inventory (exportable)

- Track orders, invoices, and request service directly

- Operator authentication and OSHA safety checklist compliance

- Analytics on fleet usage and driver behavior

TOTAL FLEET MANAGEMENT

MOVE YOUR BUSINESS FORWARD

Leverage our in-house expertise and resources to evaluate, design, and implement integrated warehouse solutions that improve your current operations.

Asset Management Platform: TW Oracle Cloud (Client-Facing Platform)

Telematic Solutions: Linde-Connect (Intelligent Fleet Management System)

Forklift Energy Solutions: Energy Solutions (Propane to Electric Program)

Service Programs: Forklift Service Plans (Repair & Service Program)

TW Site Evaluations

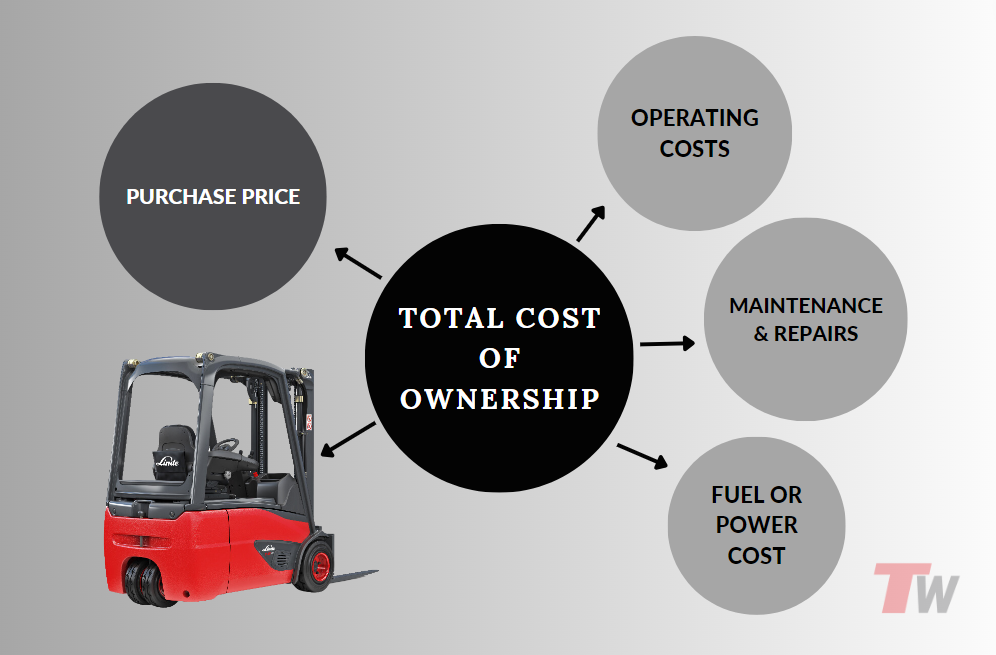

Data-Driven Solutions

We evaluate your operations, equipment, and team with a focus on Total Cost of Ownership (TCO). Using this data, our experts identify opportunities to boost uptime, cut costs, and improve overall efficiency.

- Pre-Site Evaluation: Review asset lists and determine needs.

- Site Evaluation: Analyze the building, applications, and all assets

- Post-Site Evaluation: Review results and prep post-site report.

- Next Steps: Review findings with stakeholders and discuss execution goals.

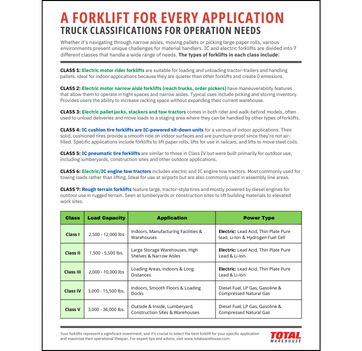

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.