6 Strategic Steps To Warehouse and Forklift Fleet Management for Max Efficiency & ROI

In today’s fast-paced warehouse and distribution environments, intelligent forklift fleet management is a necessity. Whether you operate a single facility or manage a national network of locations, the ability to track, optimize, and maintain your forklift fleet is crucial for reducing costs, improving safety, and boosting productivity.

At Total Warehouse, we offer advanced fleet management solutions tailored to your specific operational goals, leveraging the latest technology to connect your equipment, operators, and data. We’ve outlined our 6 essential steps to help you implement an effective forklift fleet management strategy.

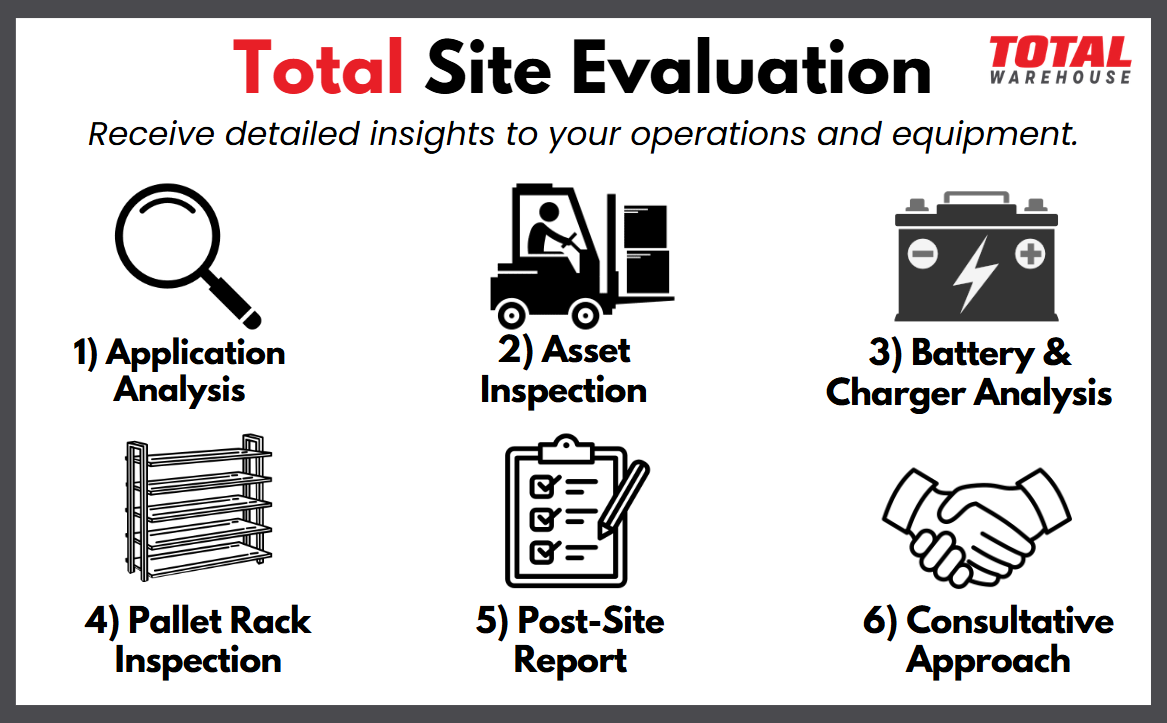

Steps To Total Warehouse Site Evaluation

![]() Step 1: Application Analysis

Step 1: Application Analysis

Before any solutions are introduced, we begin with a comprehensive application analysis. Our experts examine your operation’s size, workflows, equipment usage patterns, and peak activity times to understand the demands placed on your forklift fleet.

Why it matters:

- Identifies equipment overuse or underuse

- Helps define right-size fleet composition

- Lays the foundation for operational efficiency

Warehouse Application Analytics

- Analyze warehouse systems, inventory processes, and workflows

- Evaluate space utilization and layout efficiency

- Review picking, packing, and order fulfillment procedures

- Identify opportunities for operational improvements and cost savings

Learn More: TW Forklift Fleet Management

![]() Step 2: Asset Inspection

Step 2: Asset Inspection

Once we understand how your forklifts are used, we perform a detailed inspection of your current fleet. This includes age, service history, hours of use, and performance metrics to assess each unit’s health and value.

Why it matters:

- Uncovers high-maintenance or outdated units

- Establishes a baseline for future upgrades or replacements

- Supports long-term cost control and uptime

Equipment Lifecycle

- Aim to maximize the full lifecycle of every forklift in your fleet

- Gain complete visibility into asset performance and costs

- Track each unit through usage, maintenance, and End-of-Life

- Reduce downtime and optimize ROI with strategic fleet planning

- ALWAYS Know When to Extend, Recondition, Resell, or Dispose.

Learn More: TW Forklift Fleet Management

![]() Step 3: Battery & Charger Analysis

Step 3: Battery & Charger Analysis

Forklift batteries and chargers are critical to uptime and performance in electric fleets. We evaluate your current power system setup, including charge times, battery rotation, charger compatibility, and storage environment.

Why it matters:

- Reduces downtime from battery-related issues

- Extends battery life and reduces utility costs

- Aligns with energy-efficient charging strategies

Power & Energy Analytics

- Conduct battery testing and analysis

- Analyze charger specifications and battery requirements

- Review regular maintenance and inspection schedule

- Ensure safe charging environment and emergency equipment

Learn More: TW Energy Solutions

![]() Step 4: Pallet Rack Inspection

Step 4: Pallet Rack Inspection

Your racking infrastructure plays a big role in forklift safety and productivity. We inspect your pallet racking systems for damage, layout inefficiencies, and capacity mismatches that could hinder material flow.

Why it matters:

- Enhances operator safety

- Prevents costly racking failures

- Supports smoother, faster order picking and replenishment

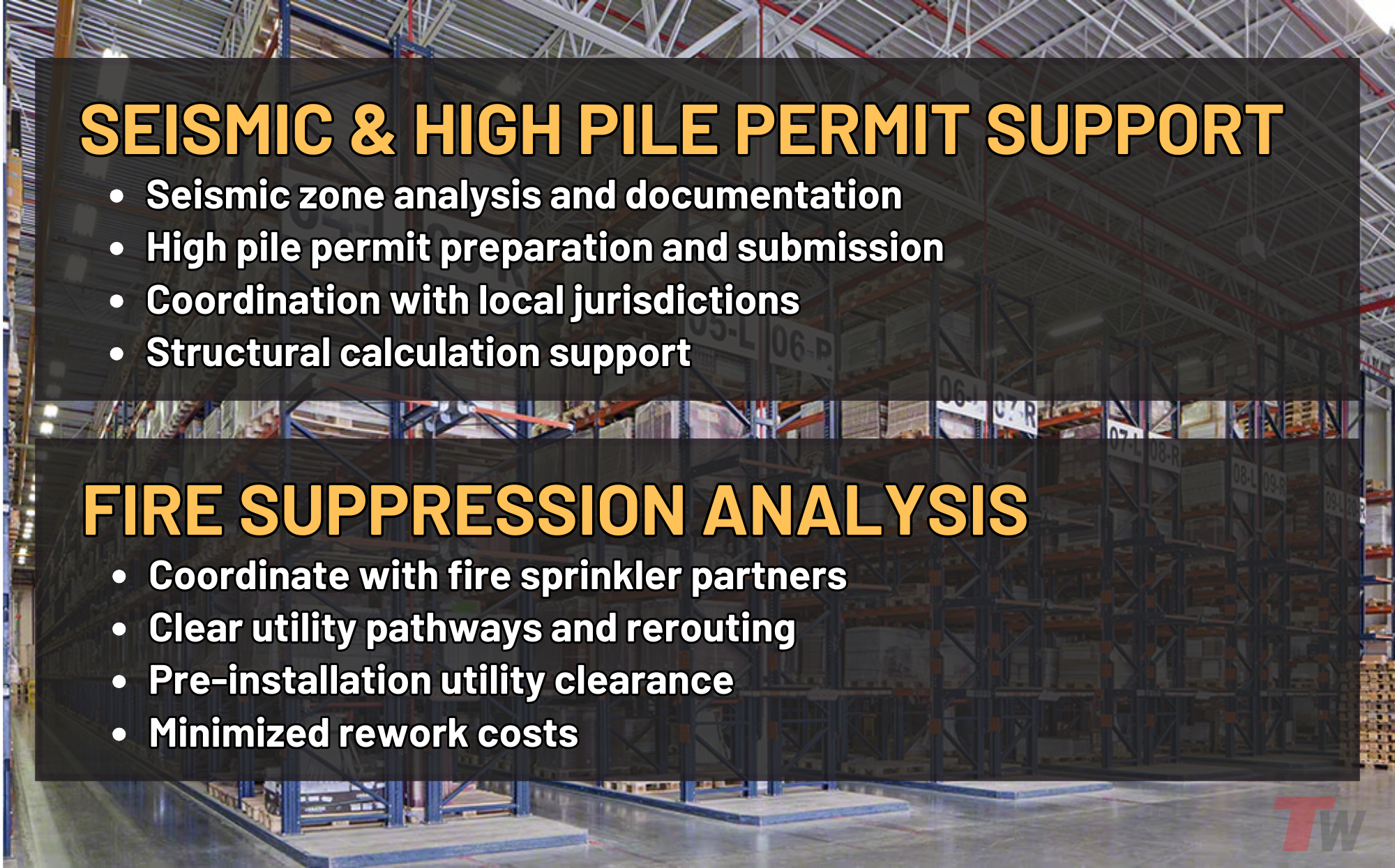

Storage Space Assessment

- Analyze space and load requirements

- Ensure systems meet structural, legal, and operational standards

- Review city permits, seismic analysis, and fire code regulations

- Analyze flue space optimizations in place or needed

- Ensure safe charging environment and emergency equipment

Learn More: TW Engineering

![]() Step 5: Post-Site Report

Step 5: Post-Site Report

After completing the above evaluations, we provide a clear, actionable post-site report. This includes condition summaries, fleet utilization metrics, safety concerns, and cost-saving opportunities—tailored specifically to your warehouse operations.

Why it matters:

- Gives stakeholders a snapshot of current challenges and opportunities

- Prioritizes recommendations for maximum ROI

- Sets up your team with a data-driven action plan

Learn More: TW Forklift Fleet Management

![]() Step 6: Consultative Approach & Ongoing Support

Step 6: Consultative Approach & Ongoing Support

Total Warehouse isn’t just a supplier—we’re your strategic partner. We deliver ongoing support through equipment replacement strategies, telematics integration, fleet performance tracking, and proactive maintenance solutions.

Why it matters:

- Drives continuous improvement and measurable savings

- Enables full visibility and control through forklift fleet management technology

- Leverages Total Warehouse’s relationship with top brands like Dematic for total material handling automation

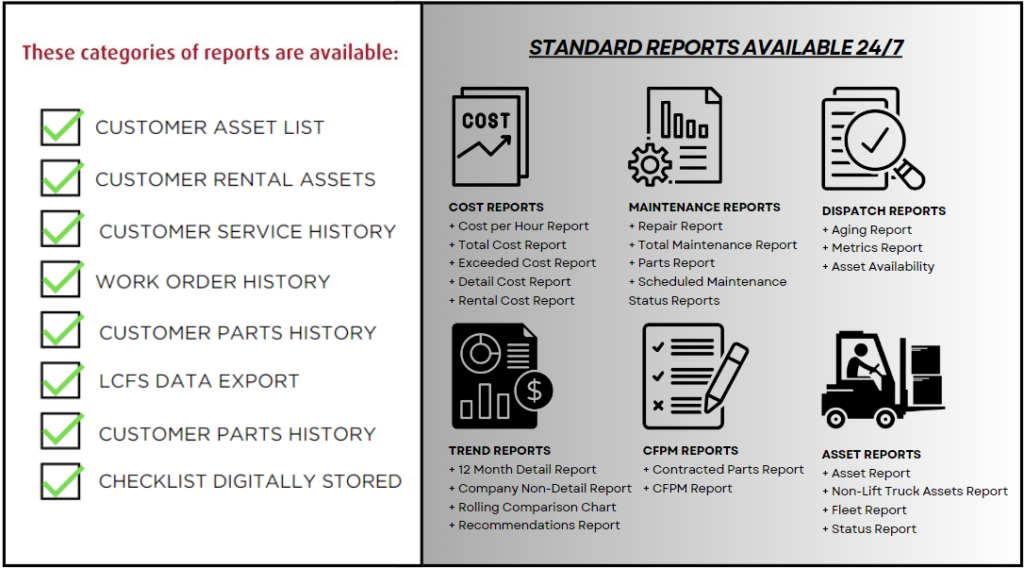

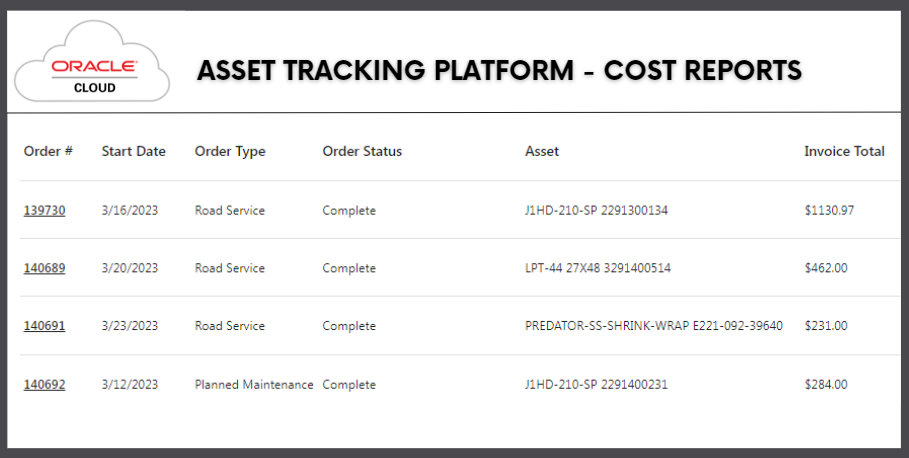

TW Customer-Facing Portal

- Monitor Multiple sites & Locations at Once

- Detailed Service Trends

- Overview of Service History (Exports Available)

- Summary of Asset Inventory (Exports Available)

- Track Orders and Invoices

- Request Service Directly from the Portal

TW Linde-Connect Telematics

- Real-time updates from production to the warehouse

- Receive data analytics on fleet usage and driver behavior

- Ensure OSHA safety checklist is completed by operators

- Improve safety with operator authentication control

Learn More: TW Forklift Fleet Management

Optimize Your Forklift Fleet and Operations with Total Warehouse

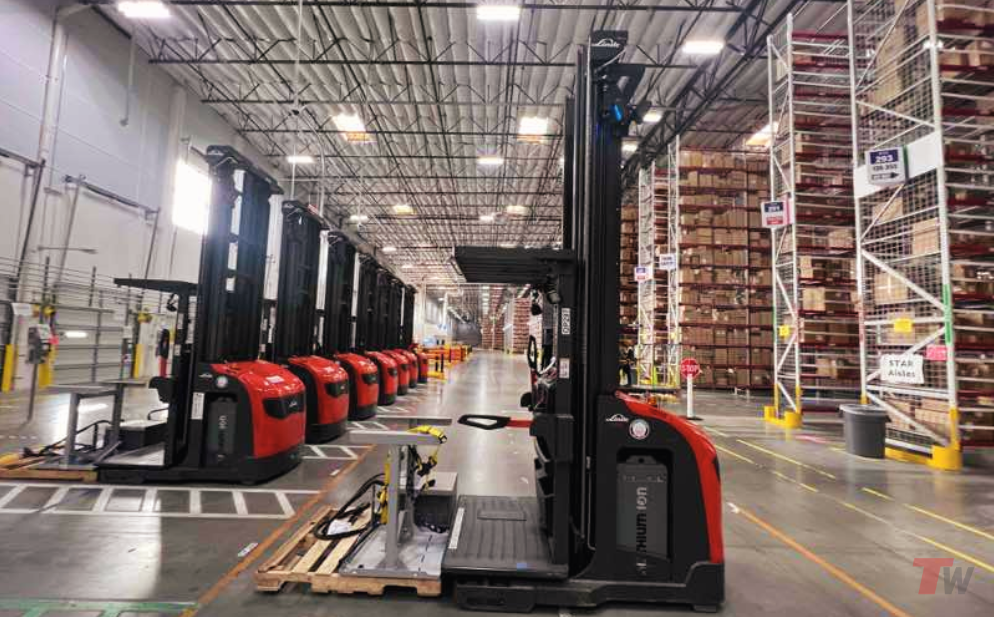

Total Warehouse offers customized, scalable forklift fleet management solutions that enhance safety and drive operational efficiency while reducing overall costs. Leveraging real-time telematics and a client-facing asset tracking portal, they provide instantaneous insights across multiple sites—covering service trends, maintenance histories, fleet utilization, and invoice tracking—to ensure your equipment consistently performs at peak levels.

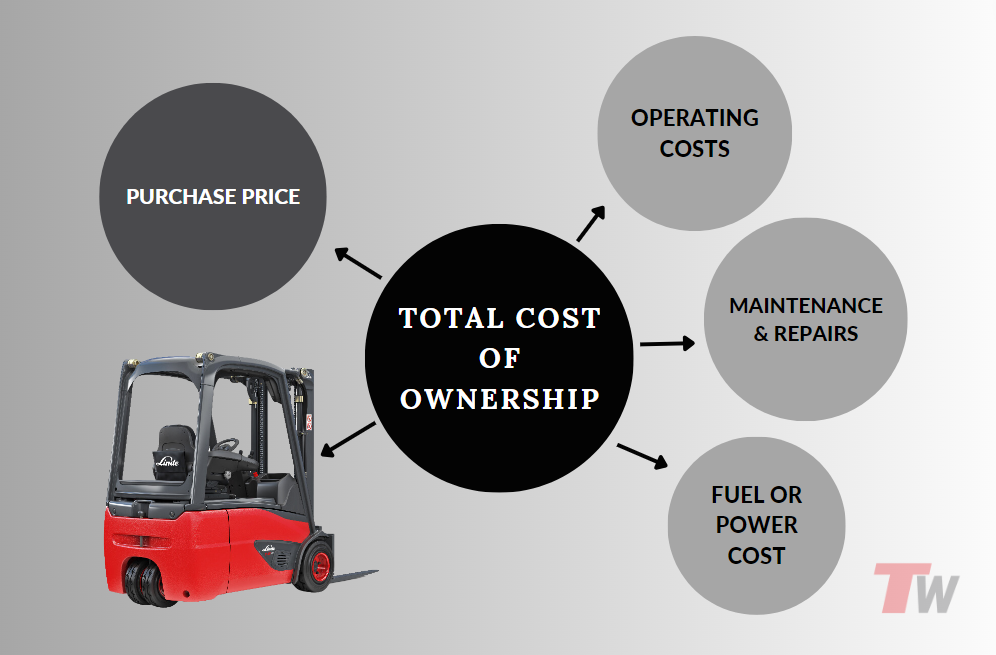

Our comprehensive approach provides full visibility into each forklift’s lifecycle—from initial site evaluation and asset inspection to battery and charger analysis and usage monitoring. Armed with this data, we help you develop strategic replacement, reconditioning, or disposal plans, optimize asset utilization, and continuously refine operations based on actionable metrics—all designed to minimize total cost of ownership and maximize return on investment.

With expertise in forklift fleet management, material handling automation, and integration with technologies like Dematic automation, industrial conveyor solutions, and Dematic AutoStore, Total Warehouse helps you turn operational data into smarter decisions. From electric forklifts to energy systems and racking solutions, our consultative services are built to maximize every square foot of your facility. Contact Total Warehouse today to explore our comprehensive range of forklifts and learn which model is right for your business.

Raising the Bar for Reliability — The Total Warehouse Standard

Total Warehouse are proud dealers for EnerSys, Dematic, Linde, Big Joe, UniCarriers, and Landoll. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.

<table>

<tr><th>Model</th><th>Capacity</th><th>Best Use Case</th><th>Key Feature</th></tr>

<tr><td>Toyota Core Electric</td><td>Up to 6,500 lbs</td><td>General warehousing</td><td>Compact design</td></tr>

<tr><td>Toyota Large Electric</td><td>Up to 12,000 lbs</td><td>Heavy operations</td><td>Maximum power</td></tr>

<tr><td>Toyota 7FBEU15</td><td>3,000 lbs</td><td>Light duty</td><td>Energy efficient</td></tr>

</table>