Ensuring that the best attachment is selected for your forklift can be challenging. Simplify the process with this easy formula to ensure compatibility between your lift truck and chosen attachment. Calculate your weight Forklift Capacity for Attachments using your maximum load moment and our simple calculations.

(Truck Capacity x Load Center) / (New Load Center) = Revised Capacity

Forklift Attachment Capacity

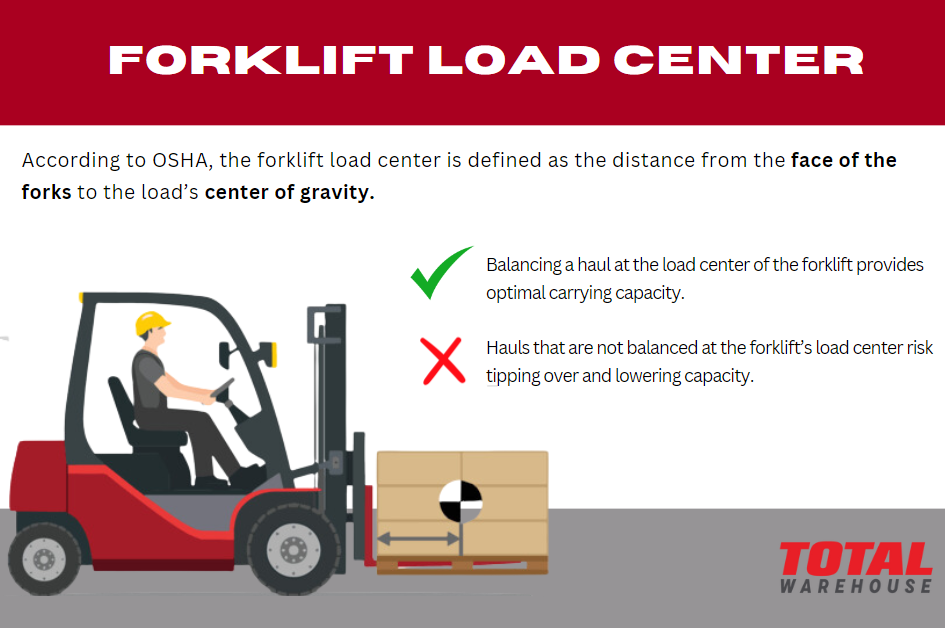

Navigating the world of forklift attachments can be daunting, especially when it comes to understanding how they affect your capacity requirements. Your journey begins with assessing your lift truck’s rating at the load center, which indicates the maximum safe weight it can handle with a centered load.

However, as you deviate from the center point, your capacity diminishes. For instance, a forklift with a 5,000-lb. capacity might only handle 4,000 lbs. if the load is shifted to a greater distance from the center. This phenomenon underscores the critical importance of load center management.

When assessing the potential capacity of attachments for your forklift, it’s vital to consider the forklift’s rating at its load center. This rating determines the safe lifting capacity of the machine and directly impacts the feasibility of using longer, high-capacity attachments such as forklift fork extensions.

Forklifts are rated based on a specific load center, meaning the farther the load is from the mast, the lower the lifting capacity. For instance, a forklift with a 5,000 lb. capacity can safely lift that weight with 48-inch forks (with a 24-inch load center). However, extending to 60 inches (with a 30-inch load center) reduces the capacity to 4,000 lbs.

Load Moment

Load Moment, a critical concept in forklift operation, calculates attachment capacity by considering weight distribution and center load distance. Ensuring safety entails avoiding overextension of the load center, which can lead to truck overturning.

Calculating Load Moment involves multiplying a load’s weight by its distance from the fulcrum, typically the axle of the front wheels for counterbalance sit-down trucks. This measure reflects the overturning force applied to the forklift’s front.

Factoring Load Center Modifications:

When modifying load centers with attachments, adjustments are crucial. By dividing the new load center by the Maximum Load Moment, revised capacity can be determined. For instance, shifting from 48-inch forks to 60-inch forks alters the load center, affecting the truck’s capacity accordingly.

(Truck Capacity x Load Center) / (New Load Center) = Revised Capacity

Load Positioning Considerations:

Real-world scenarios often involve non-uniform products and unevenly distributed pallet weights, challenging load positioning accuracy. When evaluating attachments that affect load centers, account for material size and shape. Extensions may further reduce load capacity beyond initial projections.

Explore Total Warehouse Attachments

Explore our Carton Clamp Forklift Attachments

Explore our Slip-Sheet Push-Pull Forklift Attachments

Explore our Single Double Fork – Multi Pallet Handler Attachments

Explore our Forklift Rotator Attachments

At Total Warehouse, we’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.