How to Charge a Forklift Battery

Electric forklifts, essential for material handling, rely on either lead-acid or lithium-ion batteries for power. Proper charging is crucial to extend the lifespan of your electric forklift battery, regardless of type.

Charging should ideally occur when the battery reaches 20 to 30 percent capacity, whether in the forklift or through removal and replacement. However, handling batteries, particularly lead-acid ones, poses significant risks including exposure to sulfuric acid and toxic fumes. It’s essential that only trained individuals handle batteries with care and skill to mitigate potential hazards.

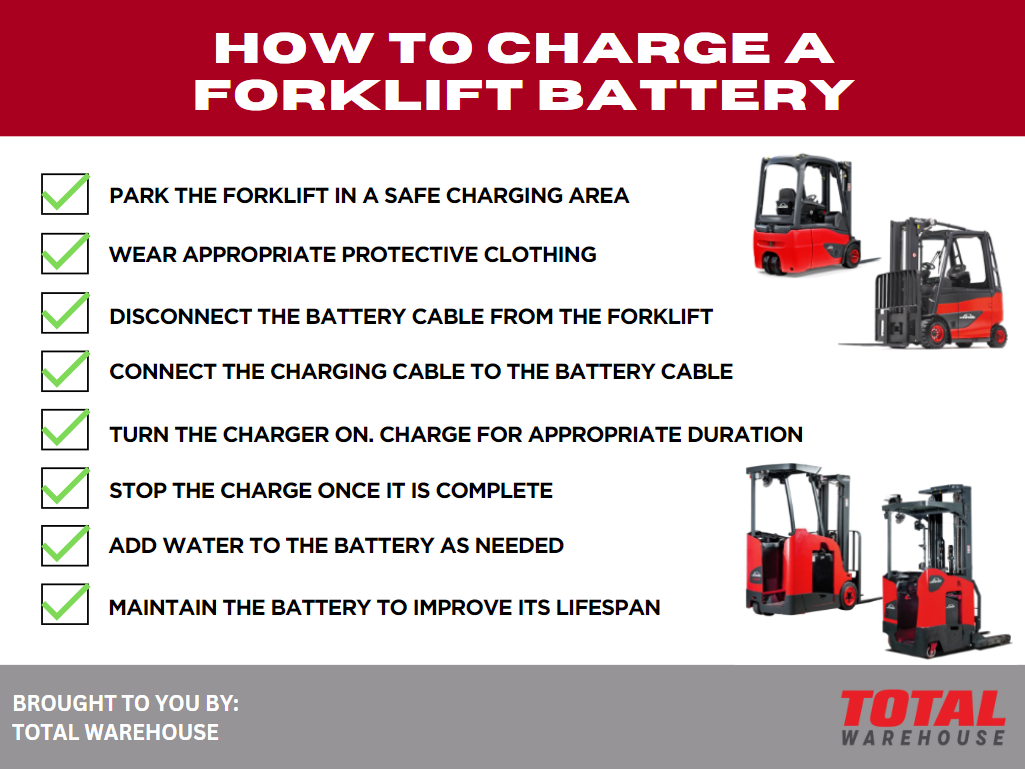

To ensure safety and maximize battery life, this post provides a detailed, step-by-step guide on proper forklift battery charging procedures. Additionally, it offers valuable tips on battery maintenance to help you safeguard both yourself and your job site.

Learn About the Forklift Battery Charger Basics

Steps to Take Before Charging a Forklift Battery

1. Prepare the Charging Area: Move the forklift to the designated charging area before beginning the charging process.

2. Ensure Safety Features: Charging stations should have adequate ventilation to dissipate hydrogen vapors, especially if there’s a risk of ignition due to sparks.

Additionally, essential safety equipment such as fire protection systems or fire extinguishers, safety showers, eyewash stations, and no smoking signs must be present.

Acid neutralization materials should also be readily available.

3. Refer to OSHA Guidelines: For comprehensive information on forklift safety, including guidelines on batteries and charging procedures, consult the OSHA website.

Once the forklift is properly parked in the charging area and all safety measures are in place, you’re ready to proceed with the charging process. Ensure strict adherence to safety protocols to mitigate any potential risks.

How to Safely Charge Your Forklift Battery

1. Prepare the forklift: Apply the parking brake and turn the key to the off position. Raise the seat to access the battery compartment.

2. Safety first: Don the proper personal protective equipment (PPE), including safety glasses, a face shield, gloves, and an apron.

3. Choose the right charger: Select a charger that matches the output voltage and capacity of the forklift battery.

4. Inspect charger cables: Check cables for any signs of damage or wear. If any issues are found, contact a forklift battery repair service.

5. Disconnect the battery: If necessary, remove the battery from the forklift using proper equipment such as a pallet jack with a transfer carriage.

6. Secure transportation: Ensure the battery is securely positioned to prevent spillage during transport.

7. Connect the charger: Safely connect the charger to the battery, avoiding plugging it into the forklift terminal.

8. Monitor charging: Check the charger to confirm that charging is in progress.

9. Stop charging safely: Always stop the charger before disconnecting the battery to prevent dangerous electrical arcs.

10. Add water if needed: If dealing with a flooded lead-acid battery, wait until after charging is complete and the battery has cooled before adding water.

Keep a log of watering intervals for maintenance purposes.

Follow these steps to ensure the safe and efficient charging of your forklift battery, prolonging its lifespan and maintaining optimal performance.

Total Warehouse Energy Solutions

In our commitment to providing comprehensive solutions for material handling needs, we offer a range of forklift battery chargers tailored to various environments, budgets, and battery types. Our selection includes dedicated fast and opportunity charging systems, along with CEC certified universal chargers capable of charging both lead-acid and lithium-ion batteries.

Total Warehouse are proud dealers for Linde, Big Joe, UniCarriers, and Landoll. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.