KEY FEATURES

Your Rack Safety Partner

TW brings industry expertise to ensure your racking systems meet structural, legal, and operational standards.

- Identify hidden damage early to prevent costly accidents

- Ensure OSHA and RMI compliance

- Maintain load integrity and system performance

- Minimize downtime and increase warehouse efficiency

- Receive expert documentation and repair recommendations

Learn More: Annual Rack Inspections

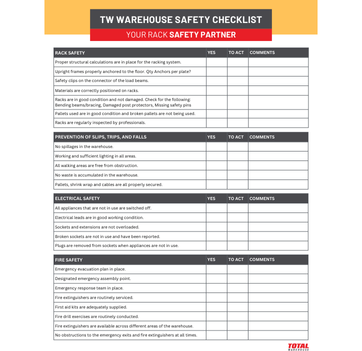

Ensure Safety & Compliance In Your Warehouse

Protect your team, inventory, and infrastructure with racking solutions engineered for clear aisles, safe forklift access, and regulatory compliance.

TW Engineering Delivers:

- Rack Inspections & Maintenance: Annual audits and proactive checks to prevent hazards and downtime.

- Code Compliance: Engineered systems that meet OSHA, ADA, and fire safety standards.

- Smart Safety Features: Pallet stoppers to prevent overhang, wire decking for sprinkler access, and clear aisle planning.

Learn More: Rack Safety Checklist

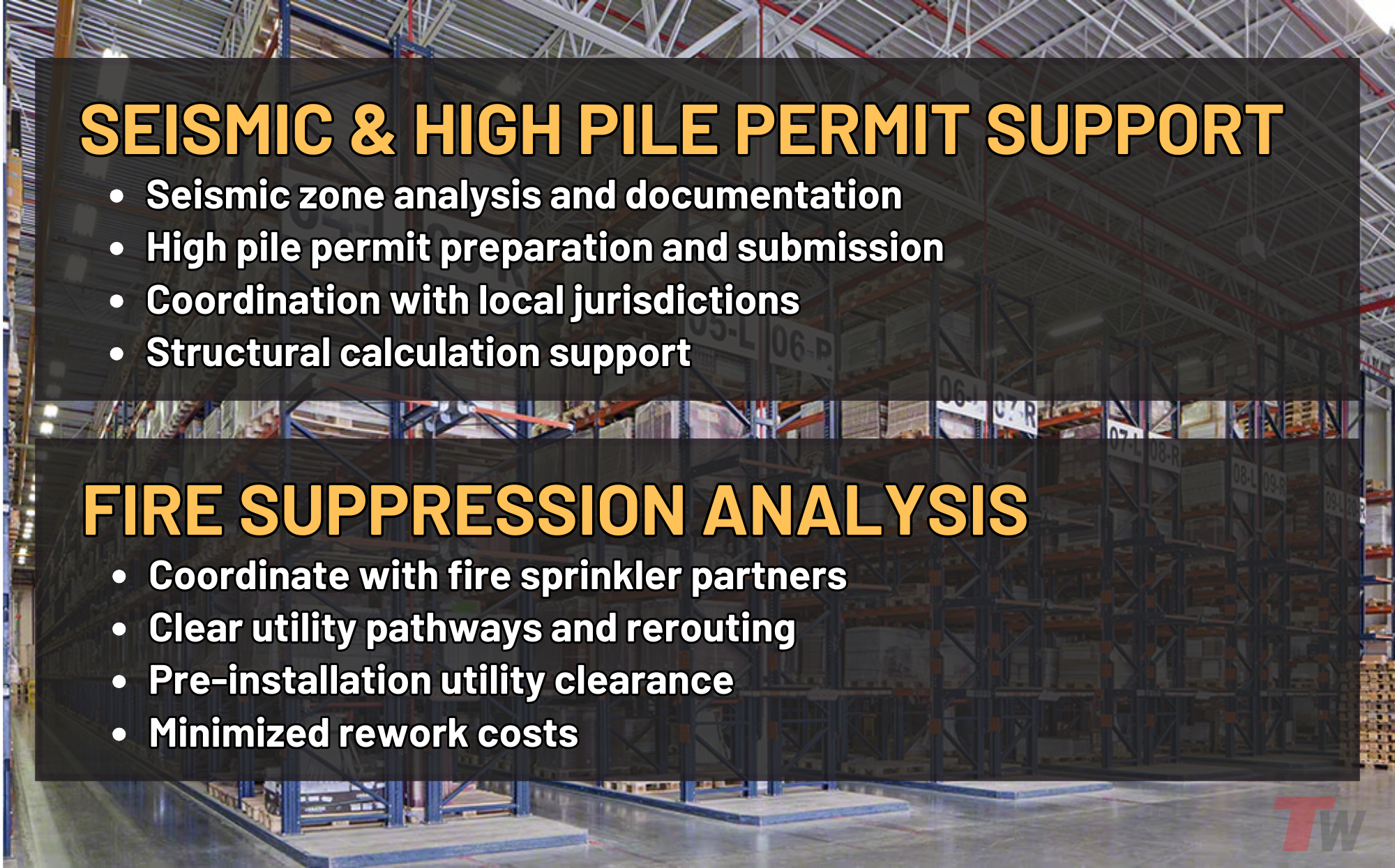

Permits. Codes. Covered.

Our team handles city permits, seismic analysis, and fire code regulations to protect your investment. You won’t need to chase approvals—we bring them to you.

- High pile permits and fire code clearance

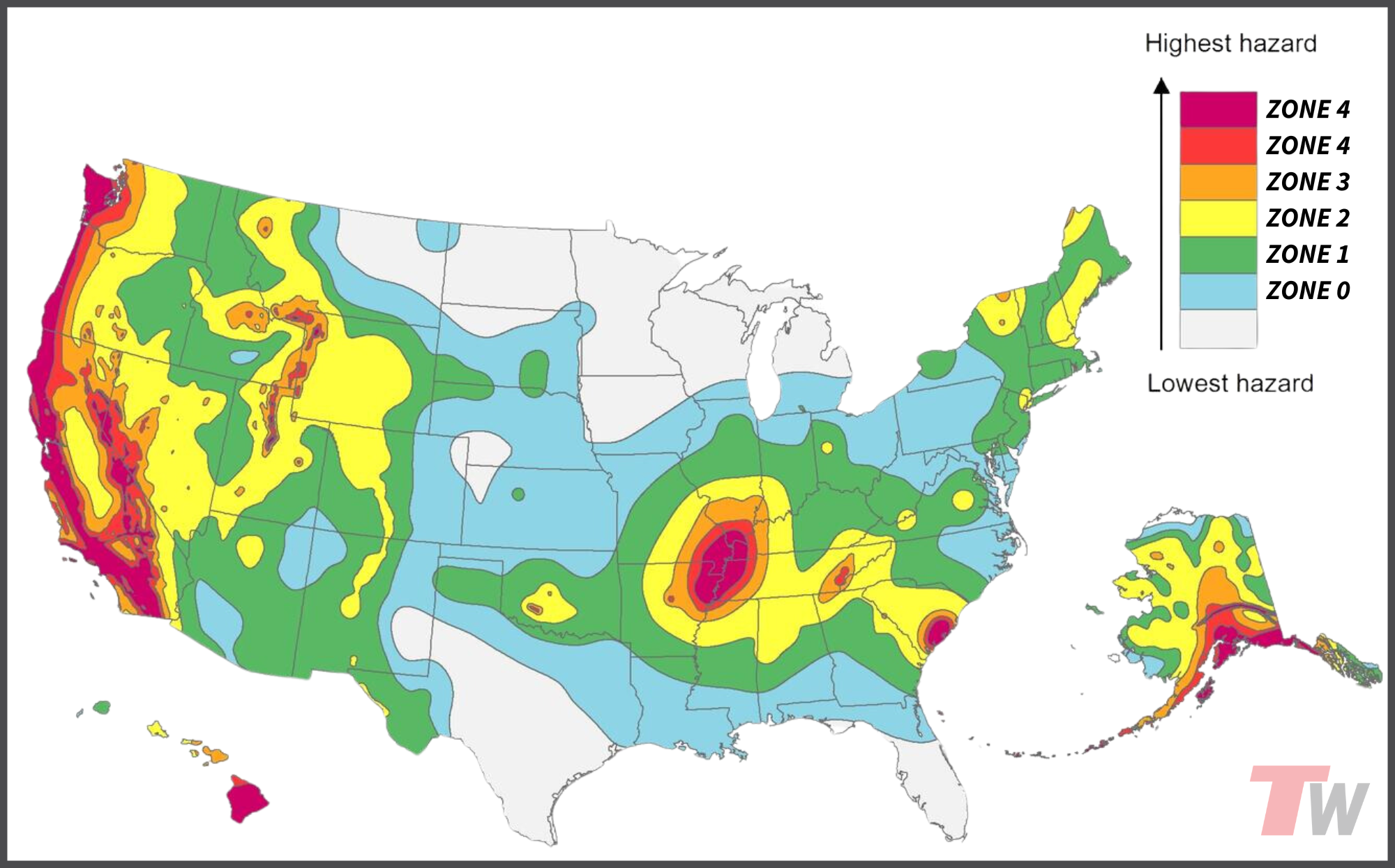

- Seismic zone requirements

- Signed-off engineering drawings

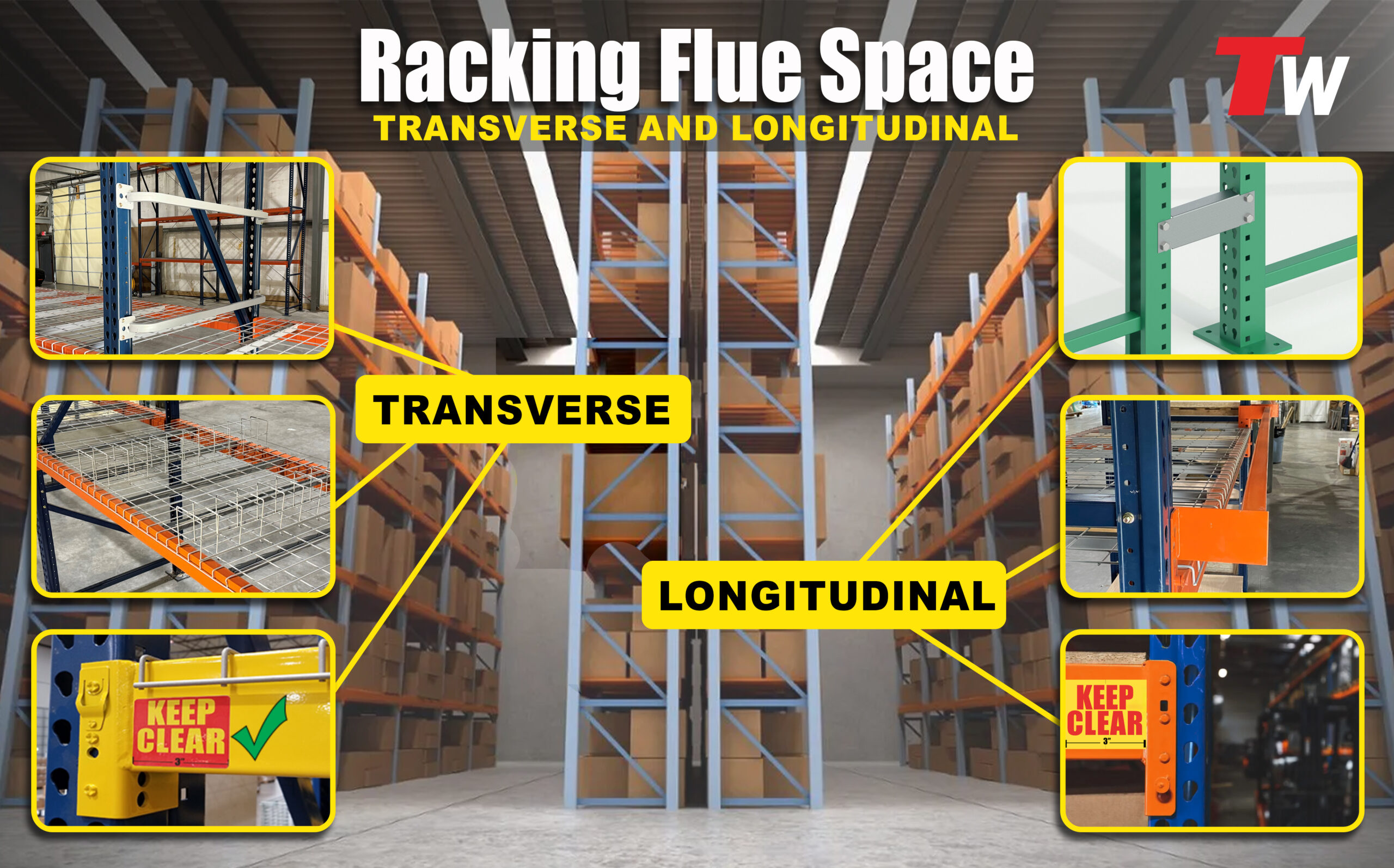

Flue Space Optimization

Proper transverse and longitudinal flue spacing is essential for fire safety and sprinkler performance. Our layouts ensure code-compliant spacing, using tools like indicator bars and labels to maintain clearances and support NFPA requirements.

- Transverse Spacing: Between pallets side-to-side

- Longitudinal spacing: Between rack rows front-to-back

- Supports NFPA and local fire codes

- Enhances sprinkler coverage and emergency response

- Reduces risk of blocked water distribution

Learn More: Pallet Rack Flue Space

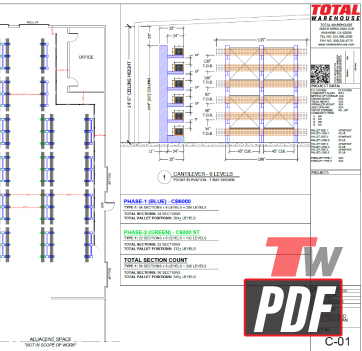

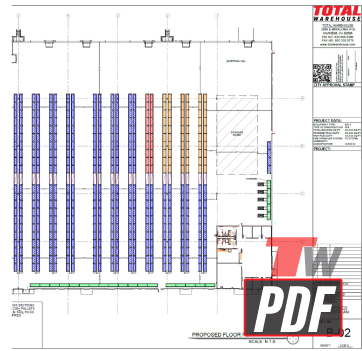

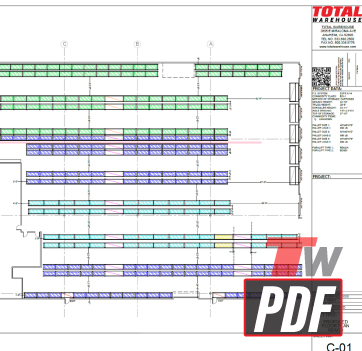

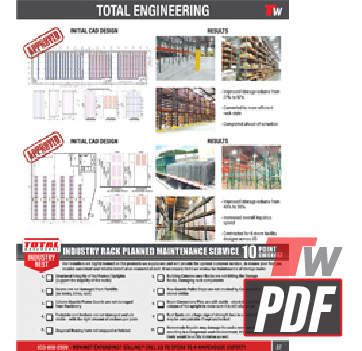

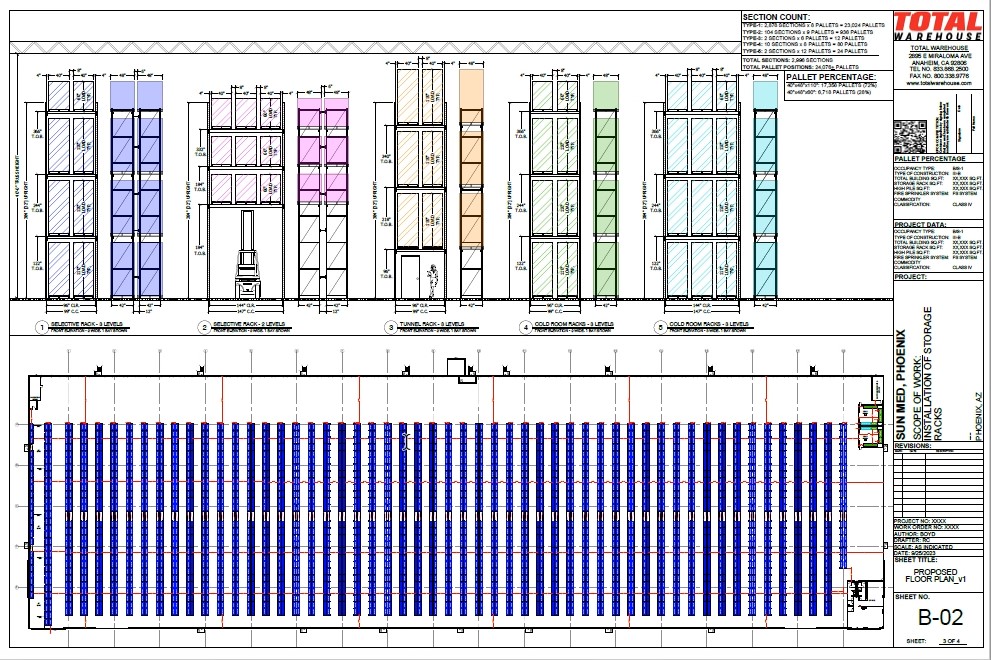

Engineering Design Services

Need a CAD layout? Whether you’re optimizing warehouse efficiency or applying for a building permit, our engineering team delivers tailored storage and processing solutions that align with your budget, labor, and equipment needs.

TW Engineering & Design Deliverables:

- Concept & Installation Drawings

- Floor Plans, Racking Elevations, Site Plans

- CAD Drawings, Load Capacities & Seismic Design

- Inventory Slotting & High-Pile Analysis

Backed by experience across industries—food & beverage, retail, 3PL, manufacturing, and more—we design to fit your unique operational goals.

Seismic Engineering & Structural/Building Permits

Seismic zones dictate the earthquake resistance required for safe, compliant racking. We provide structural and seismic calculations to prevent collapse, protect inventory and staff, and minimize downtime in your area.

TW Engineering & Design Experts Provide:

- Seismic-compliant racking with structural analysis

- Code-compliant, permit-ready documentation

- Full support with permit submittals and regulatory compliance

High Pile Storage Analysis & Permits

High pile storage without proper permits can delay operations or result in code violations. This ensures safe storage, fire department access, and proper suppression—critical for safety, compliance, and business continuity.

TW Engineering & Design Experts Handle:

- Expert guidance on high pile storage fire code compliance

- Permit-ready layouts and fire protection plans

- Complete submittal process with local fire departments and municipalities.

- Maximized vertical storage while staying inspection-ready

Trusted Manufacturer Partners

Partnerships With Leading Racking Manufacturers

Our products are built for strength, durability, and long-term performance in demanding warehouse environments.

- Heartland, Nucor/Hannibal, Interlake/Mecalux, UMH

- Additional Partners: Maverick, Steel King

Aligned with Industry Standards By Reputable Organizations

Our solutions are designed to reflect safety, compliance, and performance.

- MHI (Material Handling Industry) | MHEDA (Material Handling Equipment Distributors Association)

- RMI (Rack Manufacturers Institute)

- NFPA (National Fire Protection Association)

🏗️ Warehouse Racking & Engineering – Q&A

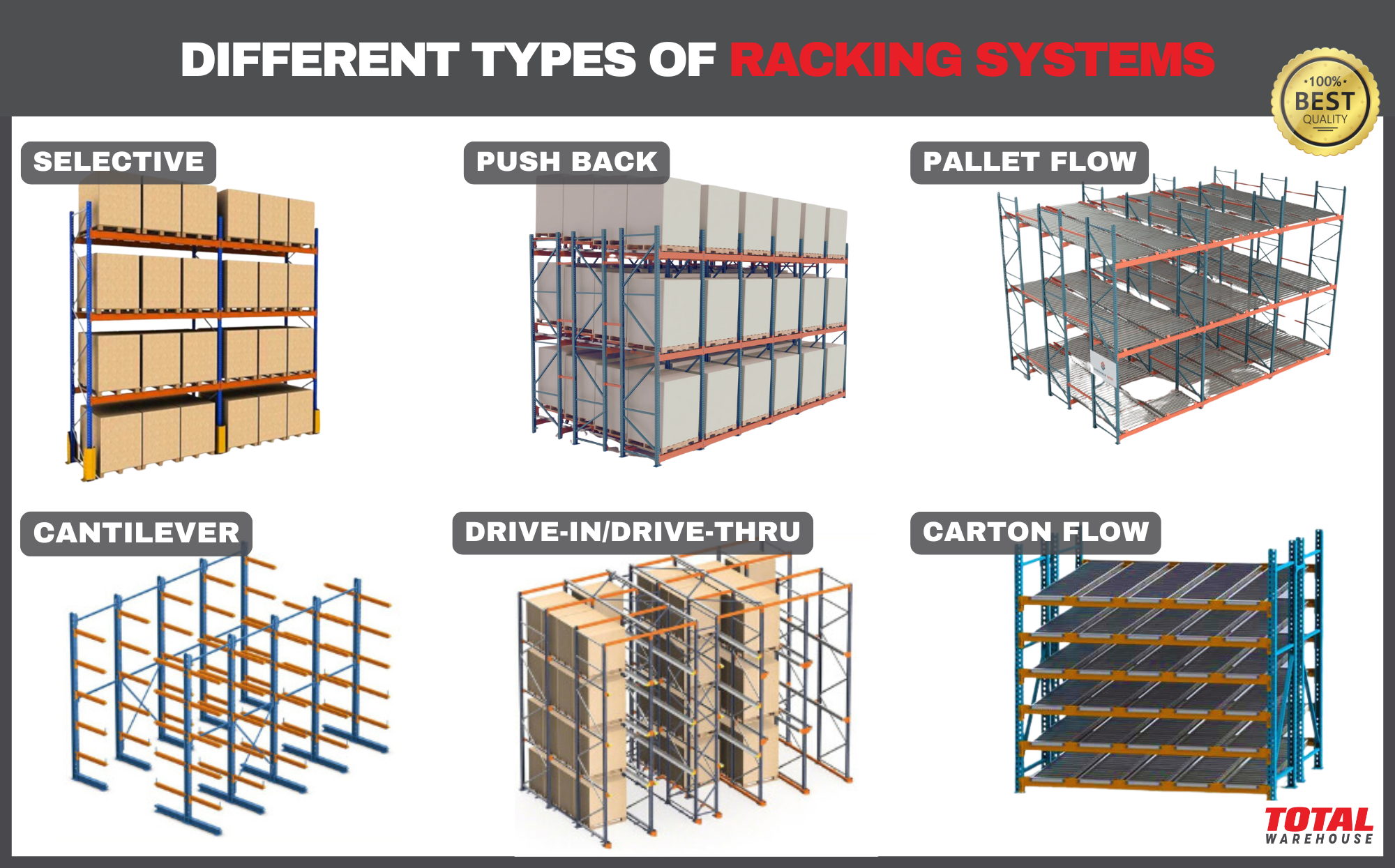

1. How do I know which pallet racking system is right for my warehouse?

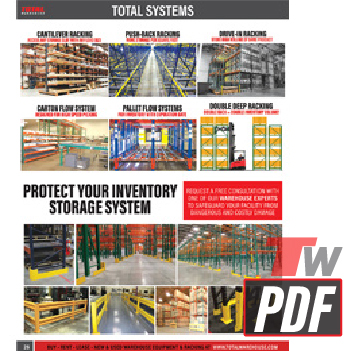

Choosing the right pallet racking configuration is essential to meet your storage needs. With various options available, it’s important to select the system that best fits your space and inventory requirements. From drive-in racks to push-back systems, understanding your needs can help you optimize your storage efficiency.

Our experts assess your inventory, workflow, space, and goals to recommend the best system for your needs—whether it’s selective, push-back, drive-in, or cantilever.

2. What services do your engineering and design experts offer?

We provide site assessments, seismic calculations, CAD drawings, slotting analysis, equipment matching, and permit-ready documentation.

3. Can you help with seismic requirements and compliance?

Yes, we offer seismic-compliant racking designs complete with structural analysis and permit documentation for areas in seismic zones.

4. What is high pile storage, and do I need a permit?

High pile storage involves stacked goods over a certain height. We manage permit submittals and fire safety planning to ensure code compliance and smooth inspections.

5. Do you provide custom racking layouts?

Absolutely. We design efficient, space-maximizing layouts tailored to your product types, throughput rates, and long-term growth plans.

6. How can your team help with warehouse safety?

We ensure OSHA and ADA compliance, provide pallet stoppers, wire decking for fire safety, and offer annual rack inspections and maintenance support.

7. Do you perform site visits and assessments?

Yes, we perform full site analyses to understand your space, equipment, and structural conditions before designing your system.

8. Can you assist with installation services?

Yes, we manage full installation—from concept to completion—ensuring correct assembly, anchoring, and safety compliance.

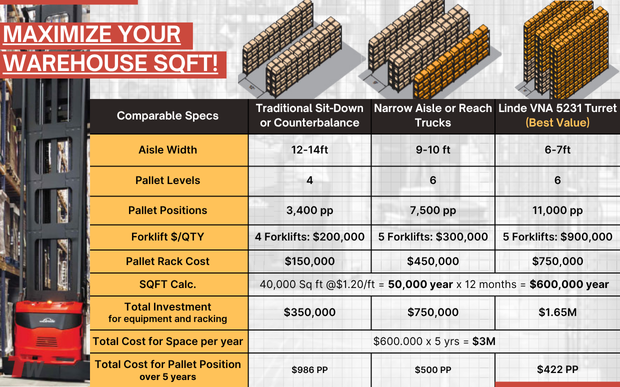

9. How do you maximize warehouse space?

We use data-driven design to improve vertical storage, reduce aisle space where possible, and match equipment to your load and workflow needs.

10. What industries do you serve?

We serve a wide range of industries including food & beverage, retail, automotive, 3PL, electronics, and manufacturing.

11. Do you help with racking permits?

Yes, we handle the full permit submittal process, including code compliance checks and communication with local officials.

12. What makes your racking systems more efficient?

We integrate lean practices, advanced engineering, and ERP/WMS compatibility into each design for faster throughput and reduced waste.

13. What types of racks do you work with?

We support a wide range of systems, including Interlake, Mecalux, Penco, Speed Rack, Structural Rack, Unarco T-Bolt, and many more.

Rack Examples Include: Interlake Old Style Tear Drop, Kingway Tear Drop, USP Tear Drop, Speed Rack Tear Drop, Mecalux Tear Drop, Lyon Metal Tear Drop, Interlake New Style Tear Drop, Space Rack Tear Drop, Bull Dog Tear Drop, Highline, Buckley, Unarco T-Bolt, Penco Slotted, Redi Rack, Frick Gallagher, Keystone, Palletier Old Style, Speed Rack, Husky Slotted, Buckley Master, Republic Keystone, Triple A, Cantennial, EMI Arrowstar, Amerilock, Prest Tear Drop, Palletier New Style, Sammons, EMI, Artco, Unarco 2, Ace Rack, Hiline, Prest Web Style, Strudi Built, Ridge U Rack, Burtman, Palmershile, Speed Rack, Structural Rack, Amerack and MI-Rack

14. What deliverables can I expect in a design project?

Deliverables include floor plans, elevation drawings, CAD layouts, load calculations, and slotting analysis customized for your space.

15. Why should I choose Total Warehouse?

We bring deep industry knowledge, personalized service, advanced tools, and full-scope project execution to deliver safer, smarter, and scalable racking solutions. Learn new strategies for optimizing space utilization in your warehouse.

Check out our article on guidelines for maintaining warehouse space.

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

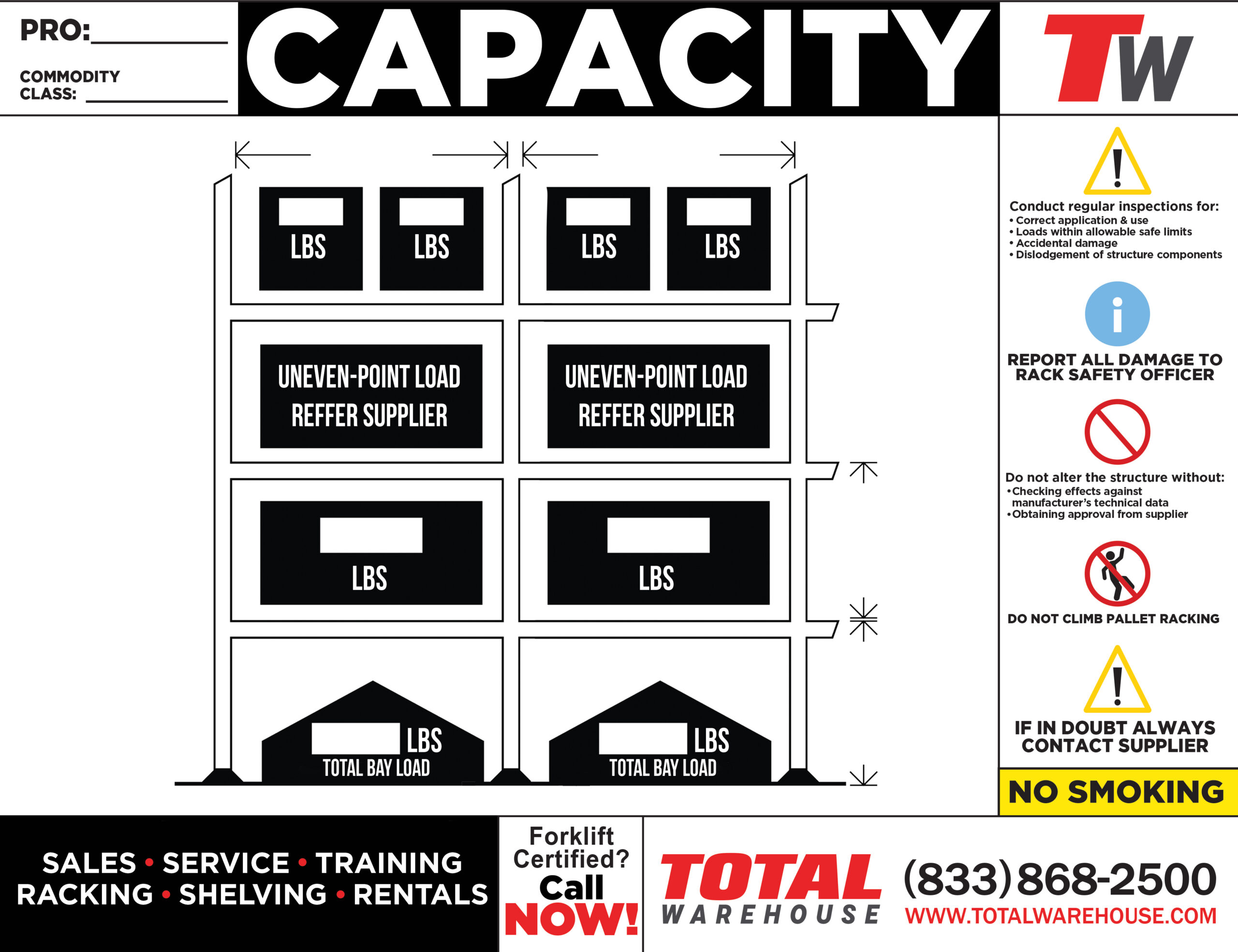

Capacity & Throughput

Achieve More in Less Time

With our expert engineering and racking solutions, you can amplify your storage capacity utilization. Increasing your pallet positions will bring huge value to your bottom line.

- Maximize Your Square Foot

- Maximize Your Equipment Investment

- Maximize Your Racking Investment

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.