Key Features

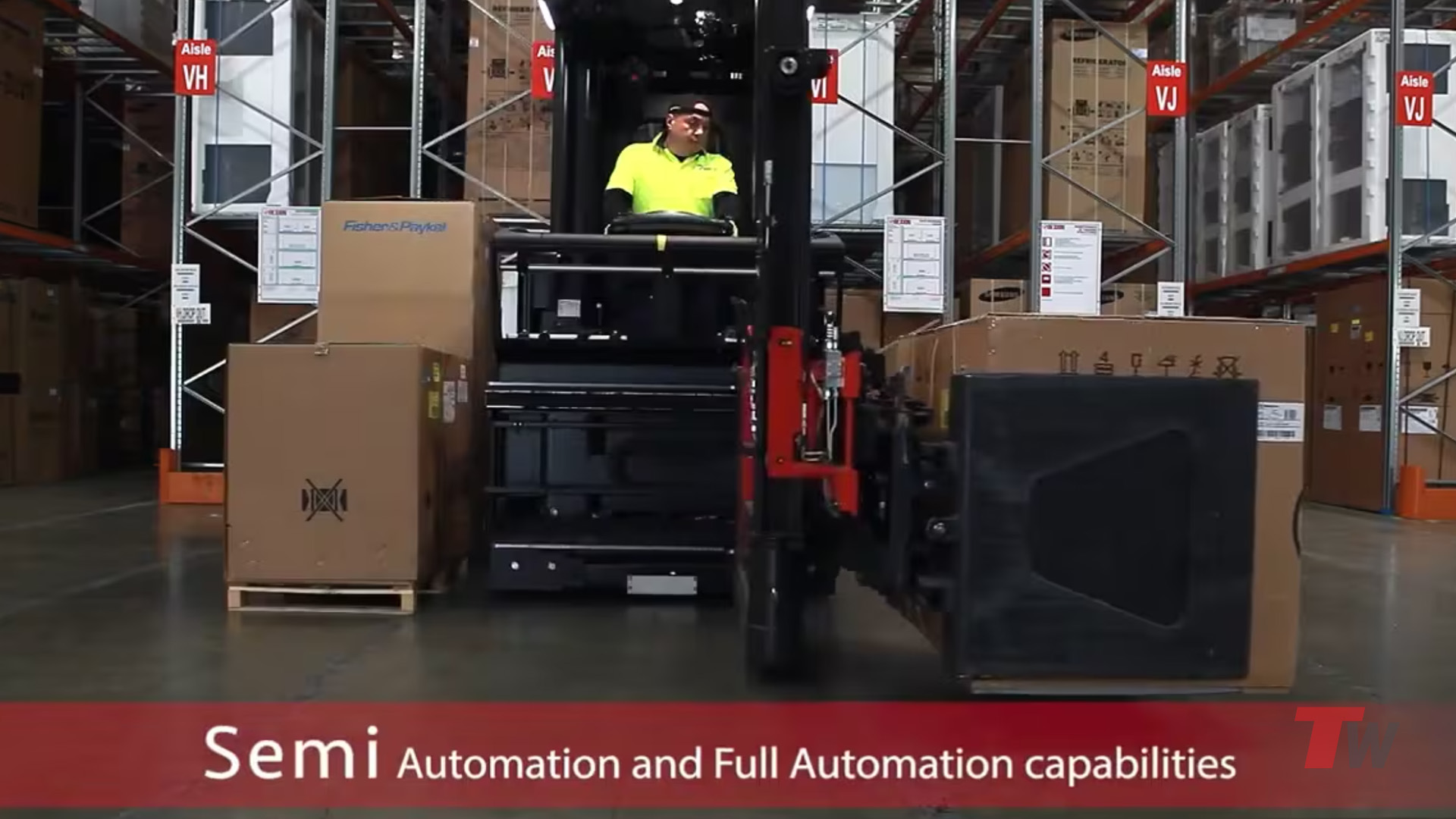

- Narrow aisle storage offers high storage density but places demands on drivers due to numerous storage locations, often resulting in misplaced pallets.

- Linde Warehouse Navigation addresses this challenge by guiding drivers efficiently, enhancing productivity in narrow aisle warehouses.

- Avoid errors and maximize productivity in the warehouse by identifying the sources of errors in advance and show the drivers the most efficient path between the 2 points in the high rack every time.

- With the K trucks superb cabin layout the operator feels immediately at ease and acclimatized.

- With generous space for freedom of movement, the cab offers a comfortable operational environment for fatigue-free working and promotes optimum efficiency and productivity.

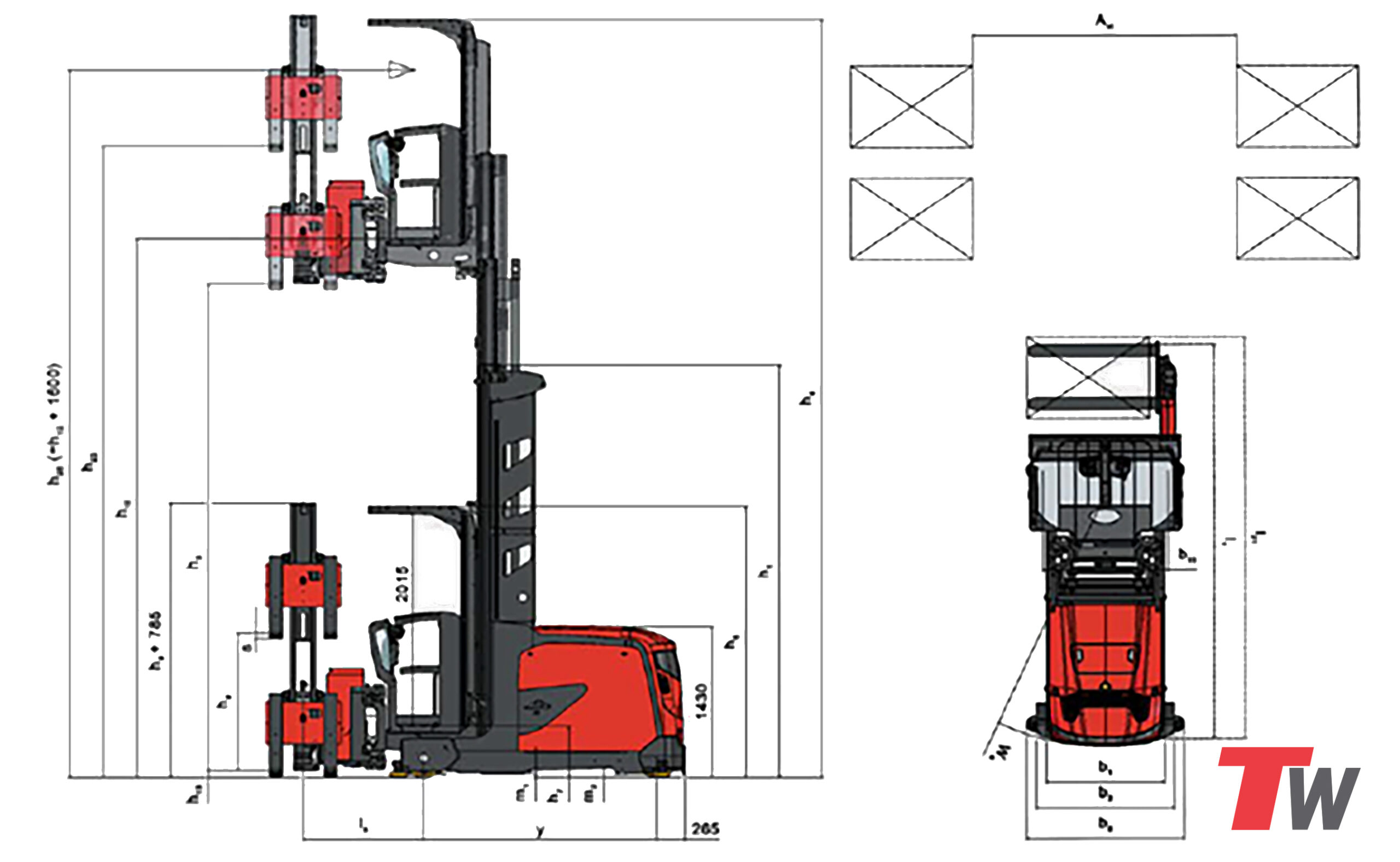

- Unique modular design concept enables the perfect specification for each application

- Combination of different lift and drive motors (light, normal, heavy duty)

- Truck capacities from 1,000 to 3,000 lbs

- Cabins optimized for picking or storage or combined use

- Various chassis width

With efficient load handling in high rack warehouses, calculations come down to the millimeter. Very narrow aisle trucks are used for working at great heights. The aisles are narrow and the distances to the rack are calculated very precisely. Because of that, even the slightest unevenness in the warehouse floor can become a problem and cause the truck to oscillate dangerously.

Before commissioning a new VNA truck, a service technician must ensure that there are no safety risks attached to driving on any of the warehouse floors. If the floors are uneven, the technician must reduce the maximum speed of the truck: This results in lower handling performance and economic losses.

This is a problem that many warehouse operators had to contend with in the past, but Ttoal Warehouse and Linde Material Handling now offer an innovative solution with its Active Stability Control (ASC) assistance system for the K truck.

The Linde 5321 offers an Operators Cabin that is extremely robust, but opens easily for convenient entry and exit. The comfortable cushioning supports that operator when leaning over the barriers.

- Reduced shock and vibration due to isolation of cabin from chassis.

- Easy and low access height.

- Various comfortable and adjustable seats.

- 3 different Cabins available– Combi cabin (combined picking/ stacking) – Comfort cabin with +100mm more depth – Cold store cabin (-30°C)

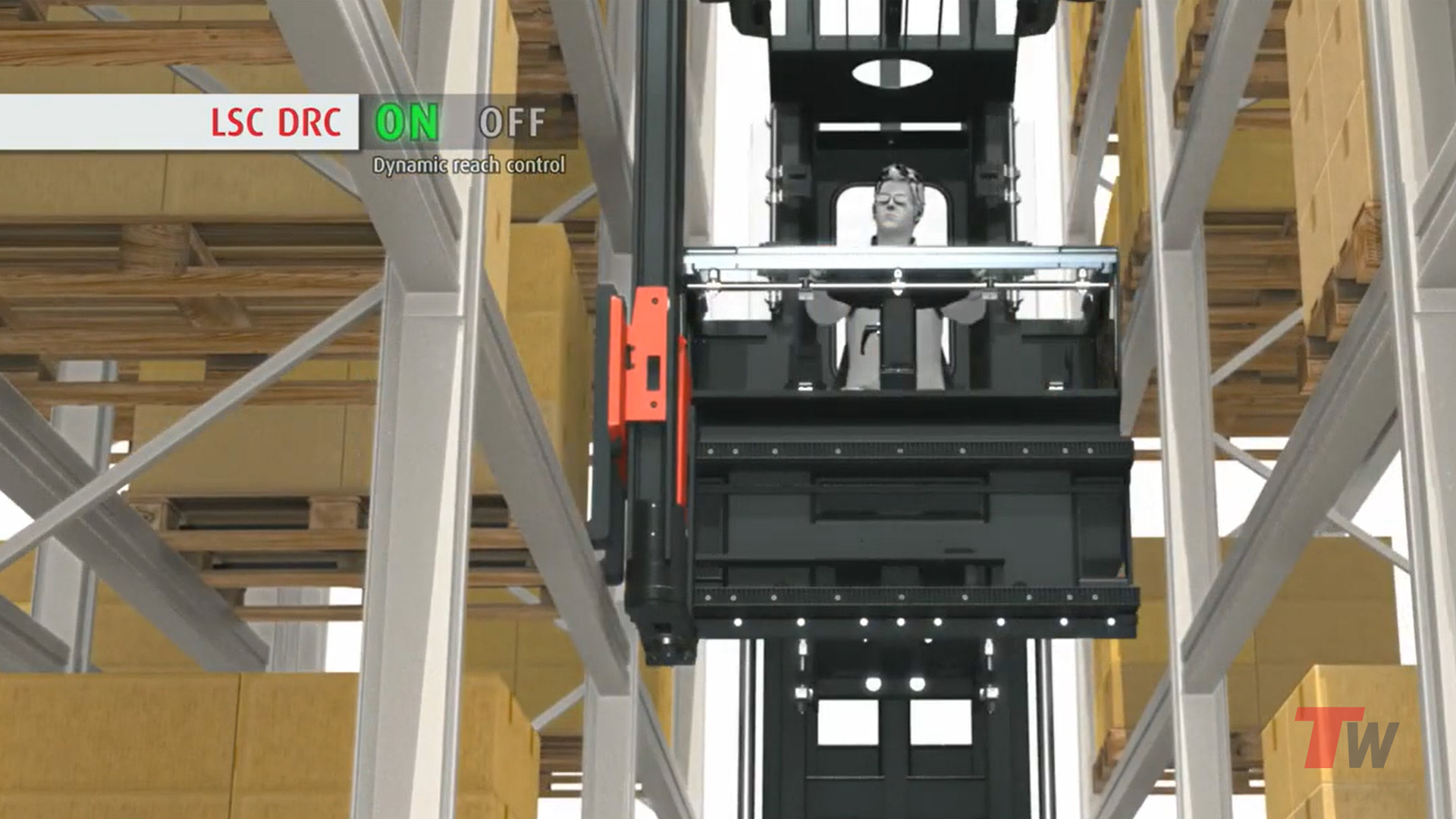

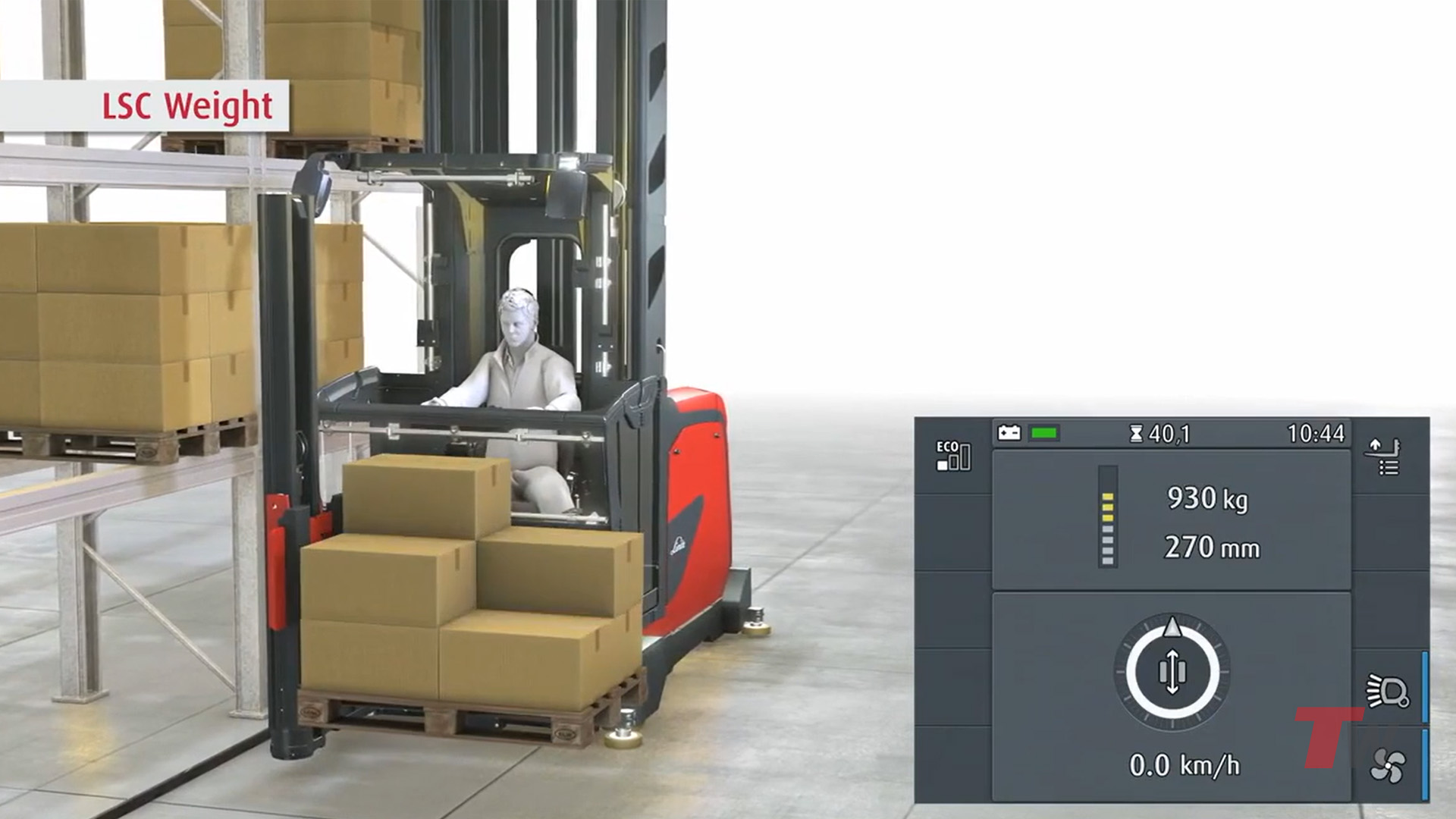

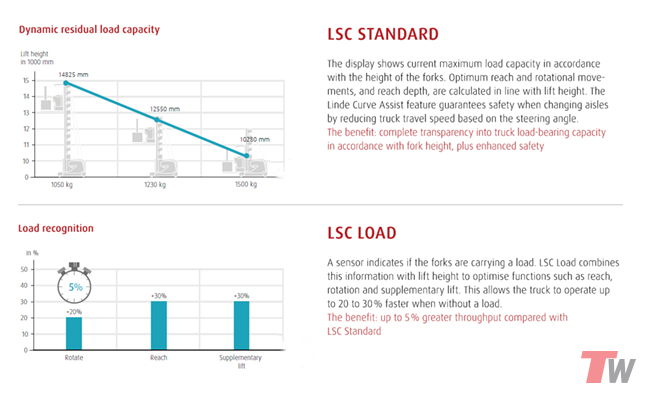

Linde has developed powerful, pioneering technology to ensure optimum control of its VNA man-up and man-down trucks: Linde System Control (LSC)

LSC emplys a sensor to detect the height of the fork, and calculates the maximum residual load capacity. The speed of the truck is automatically adjusted in accordance with the detected height. This all occurs in real time and is displayed to the operator.

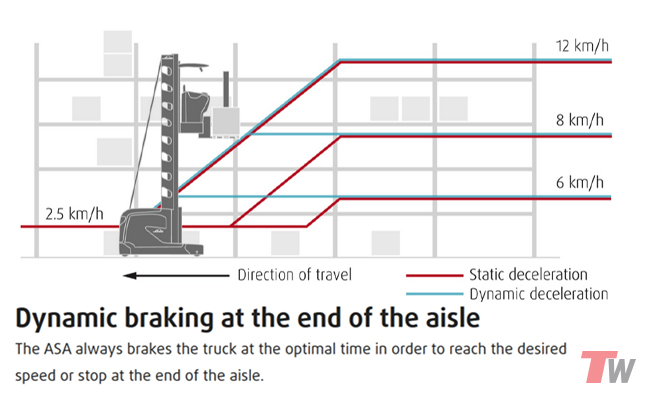

With the help of the Aisle Safety Assistant (ASA) from Linde Material Handling, the very narrow aisle truck adjusts its movements to the warehouse environment. This significantly reduces the risk of collisions with the warehouse’s infrastructure as well as damage to the truck, the goods and the working environment.

The aisle safety assistant works similarly to the passive driver assistance systems used in cars, which help the driver to control the vehicle. With the help of the ASA, the very narrow aisle truck navigates using RFID tags embedded in the floor or barcodes that are affixed to the rack columns. This enables the truck to determine where in the warehouse the very narrow aisle truck is situated at any time. At the same time, the height sensor determines the height of the cab. The truck control unit therefore knows the truck’s exact position and current height dimensions at all times.

To avoid collisions, obstacles that protrude into the rack aisle are marked on the digital map with their position and dimensions. If the truck approaches the marked area, the ASA prevents the driver from driving into it. The system knows the exact dimensions of each truck at all times, including the mast, cabin and fork position and stops the very narrow aisle truck automatically, before it reaches the obstacle.

The K series man-up turret truck from Linde Material Handling enables high turnaround capacity for order picking and handling processes in high rack warehouses. The powerful drive trains make this possible, as the truck can move and lift at the same time. Also, even at high lift levels the speed remains high, and a high level of residual lift capacity is available.

Various assistance systems are available that help to navigate accurately through the warehouse or to avoid obstacles. In particular, the Linde System Control improves the process; depending on the version, the system adjusts the lift and travel speed according to the weight being transported. There are various versions of the mast, chassis, battery and cab for the very narrow aisle trucks, which can be combined according to usage requirements. There are around 10 million possible truck configurations.

Total Warehouse has been servicing the material handling needs of a large variety of industries for over 60 years. The Linde forklifts are distinguished by their innovative industrial technology, ensuring customer confidence in the brand. Efficient energy management and reduced operating costs allow us to reach a level of up to 40% savings compared to other brands.

Competitive Rates

Available for Rent, Lease, and Sale

Total Warehouse has a massive rental fleet ready to be delivered to your business at a moment’s notice. We offer daily, weekly, and monthly rental rates that allow you to maximize operations at the bare minimum cost. We have you covered with the top material handling products for operational optimization that is customized to your specific needs.

| Model | Capacity (lbs) | Lift (ft) | Battery voltage / rated capacity |

| KTURRET_5231_0.7 | 1400 | 18' | 48 V |

| KTURRET_5231_0.9 | 1800 | 23' | 80 V |

| KTURRET_5231_1.5 | 3000 | 51' | 80 V |

Strong motors enable high lift- and driving-speeds, while the ergonomic control panel enables quick load handling with minimal hand movement. Assisting systems like LSC or the Aisle Safety Assist support the operator for maximum throughput in safe operation. The innovative Active Stability Control assistance system ensures a smooth and fast travel speed even on floors that do not comply with VDMA guidelines. The electro-mechanical sensors identify and automatically compensate for unevenness of the floor to achieve maximum handling performance.

Strong motors enable high lift- and driving-speeds, while the ergonomic control panel enables quick load handling with minimal hand movement. Assisting systems like LSC or the Aisle Safety Assist support the operator for maximum throughput in safe operation. The innovative Active Stability Control assistance system ensures a smooth and fast travel speed even on floors that do not comply with VDMA guidelines. The electro-mechanical sensors identify and automatically compensate for unevenness of the floor to achieve maximum handling performance.

Strong motors enable high lift- and driving-speeds, while the ergonomic control panel enables quick load handling with minimal hand movement. Assisting systems like LSC or the Aisle Safety Assist support the operator for maximum throughput in safe operation. The innovative Active Stability Control assistance system ensures a smooth and fast travel speed even on floors that do not comply with VDMA guidelines. The electro-mechanical sensors identify and automatically compensate for unevenness of the floor to achieve maximum handling performance.

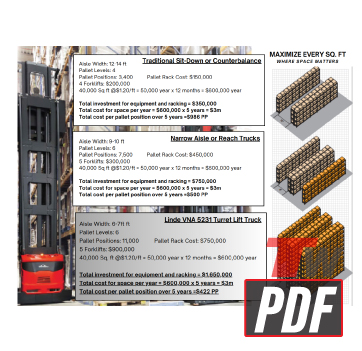

VNA Turret Truck

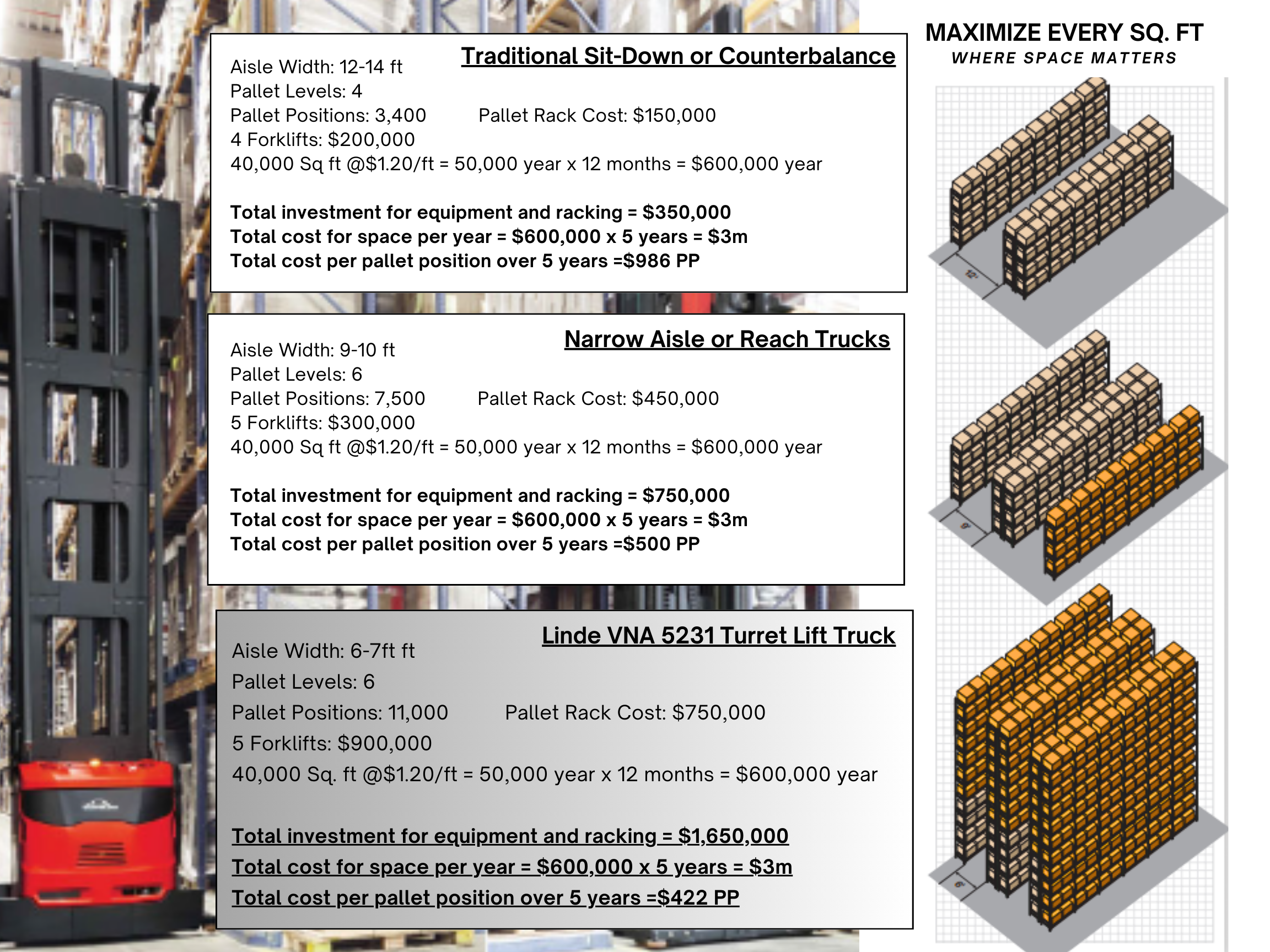

Make Every Square Foot Count

Amplify your storage capacity utilization with the LINDE VNA 5231 Turret Truck. Increasing your pallet positions will bring great value to your bottom line.

- Increase Pallet Levels

- Increase Pallet Positions

- Increase Capacity

- Get The Most Out Of Your Investment

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.