WAREHOUSE STORAGE SOLUTIONS

We Expertly Match Racking with BEST EQT Utilization for Maximizing Space

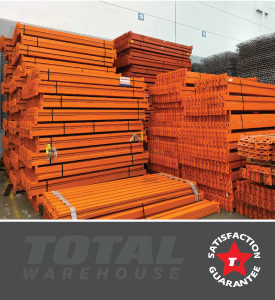

Total Warehouse is a leading industry provider of top storage solutions and material handling equipment. Our goal is to optimize the use of your space, equipment, and labor force. Our engineers determine the perfect system for your application to maximize your square space through extensive warehouse assessment, design, and development solutions. We excel in meeting diverse storage needs to make every square foot count so you can get the most out of your investment.

Our Engineering Team provides pallet racking, high-density storage, and boltless shelving solutions for every type of industry and facility. This includes engineering (space planning, on-site surveys, custom CAD layout & system designs, seismic calculations, high-pile analysis), delivery & installation, permit compliance & applications, and more.

We Match Racking with BEST EQT Use for Max Space.

Our Engineering Team delivers pallet racking, high-density storage, and shelving solutions for any industry. We optimize your space, equipment, and labor through expert design and warehouse assessment. Our goal is to maximize your storage efficiency and investment.

Maximize Every Square Foot

Strategic warehouse storage solutions transform operational efficiency through optimized vertical capacity and streamlined inventory workflows. Heavy-duty pallet storage racks form the foundation of high-performance distribution centers serving diverse industrial sectors including manufacturing, e-commerce fulfillment, and third-party logistics.

Primary benefits of specialized rack configurations:

- Selective pallet racking provides immediate access to individual pallet locations

- Double deep racking doubles storage capacity while preserving reasonable accessibility

- Drive in racking delivers maximum cube utilization for bulk inventory storage

- Push back racking enables LIFO product flow with enhanced forklift maneuverability

- Pallet flow racking utilizes gravity conveyors for automated FIFO inventory rotation

- Cantilever racking accommodates lengthy materials without obstructing vertical posts

Certified Pallet Racking Engineering & Essential Safety Features

Load-bearing calculations and structural specifications require certified pallet racking engineering compliance with local construction standards and earthquake resistance protocols. Engineering assessments determine appropriate beam ratings, column spacing, and foundation anchor requirements.

Rack protectors absorb forklift impacts protecting structural uprights from operational damage. Required flue space clearances ensure sprinkler system effectiveness and fire safety code adherence. Used pallet rack provides budget-friendly capacity expansion after thorough structural inspection and load certification.

Space-Maximizing Storage Configurations

Proven high-density warehouse storage solutions:

- Narrow aisle layouts reducing floor space requirements by 40%

- Integrated mezzanine levels doubling available cubic footage

- Continuous rack runs eliminating wasted aisle space

- Adjustable beam positioning accommodating varying product dimensions

- Specialized zone configurations optimizing product-specific storage needs

Double deep racking configurations require reach trucks but increase storage density substantially. Push back racking systems eliminate deep-reach handling while maintaining last-in-first-out inventory control. Drive in racking maximizes warehouse cube for high-volume SKUs with consistent turnover cycles. Wire decking creates secure storage platforms preventing product loss through beam openings.

Transform your facility today – contact our regional specialists for custom warehouse storage solutions featuring new and used pallet storage racks. Professional design consultation included with every project quote. Browse our extensive selection of drive-in, selective, and cantilever systems ready for immediate shipment. Complete installation services and ongoing technical support available nationwide.